asphalt plant process diagram

The Asphalt Manufacturing Process Explained Wolf Paving

Asphalt for paving goes through a mixing process in either a drum mix plant, which is a large-output and continuously operating facility, or a batch plant, which is a smaller-output plant that mixes in batches. Getting the

Hot mix asphalt production and laying process for road

For the asphalt mixing and developmental process (as shown in Figure 2 ), bitumen of standard grade 60/70, or any desired grade, was lightly heated in heat burner drums to make it soft in form...

Asphalt Batch Mix Plant Operation and Components Atlas

2017年10月7日The process of asphalt batch mix plant is explained in details below. This equipment makes hot mix asphalt in batches. Each batch is of a specific proportion of each item that we need to mix.

11.1 Hot Mix Asphalt Plants Mississippi Department Of

General process flow diagram for batch mix asphalt plants.43 (Source Classification Codes in parentheses.) 11.1-2 EMISSION FACTORS 1/95. In the reclamation

Hot Mix Asphalt Plants Emission Assessment Report US EPA

Asphalt Plant B, Clayton, North Carolina EPA 454/R-00-022 April 2000 Hot Mix Asphalt Plants General process flow diagram for batch mix asphalt plants..4 2. General

General process flow diagram for batch mix asphalt plants

Process Fugitive Emissions Open Dust Emissions BURNER 3-05-002-01, -51, TRUCK LOAD-OUT (SCC 3-05-002-14) ASPHALT CEMENT STORAGE (SCC3-os-OD2.os, .07.

11.1 Hot Mix Asphalt Plants US EPA

General process flow diagram for batch mix asphalt plants (source classification codes in parentheses). 3. 3/04 Mineral Products Industry 11.1-3 In the reclamation process, old asphalt pavement is removed from the road base. This material is then transported to the plant, and is crushed and screened to the appropriate size for further

Asphalt Production PID EdrawMax Templates

2021年3月17日A Process Flow Diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details like piping or designation. Typically, process flow diagrams of a

4. Asphalt Plant Alaska

The process is shown in the diagram on the page 4-4. Aggregate at the plant starts at the cold bins (see Figure 4-1). There are usually three or four bins for Asphalt Plants 4-2 Asphalt Pavement Inspector’s Manual Effective November 2002 dries it. The dryer consists of a revolving cylinder, a large burner, and a fan. The revolving cylinder is

Schematic representation of the wet and dry process in a

Download scientific diagram Schematic representation of the wet and dry process in a discontinuous asphalt plant. Valves (a, b, d) open ¼ wet process; valves (c, e) open ¼ dry process

Asphalt Production PFD Free Asphalt Production PFD

Asphalt Production PFD Template A simple PFD showing the process of YSG type modified asphalt production clearly. It will make you instantly productive when making similar PFDs. Download Template: Get EdrawMax Now! Free Download Share Template: Popular Latest Flowchart Process Flowchart Workflow BPMN Cross-Functional

11.1 Hot Mix Asphalt Plants Mississippi Department Of

General process flow diagram for batch mix asphalt plants.43 (Source Classification Codes in parentheses.) 11.1-2 EMISSION FACTORS 1/95. In the reclamation process, old asphalt pavement is removed from the road base. This material is then transported to the plant, and is crushed and screened to the appropriate size for

General process flow diagram for batch mix asphalt plants

Process Fugitive Emissions Open Dust Emissions BURNER 3-05-002-01, -51, TRUCK LOAD-OUT (SCC 3-05-002-14) ASPHALT CEMENT STORAGE (SCC3-os-OD2.os, .07. (SCC 305-002-12) General process flow diagram for batch mix asphalt plants (source classification codes in parentheses). Author:

Research progresses of fibers in asphalt and cement materials: A

2023年3月2日Natural plant fiber is a multi-layered thick-walled cavity structure as shown in Fig. 2.The structure consists of primary wall, secondary wall and cavity, where the thickness of the primary wall is small, and the secondary wall consists of three layers, i.e., S 1, S 2 and S 3, which are thicker and each layer has a long chain of helical cellulose

Hot Mix Asphalt Plants Emission Assessment Report US EPA

Asphalt Plant B, Clayton, North Carolina EPA 454/R-00-022 April 2000 Hot Mix Asphalt Plants General process flow diagram for batch mix asphalt plants..4 2. General process flow diagram for counter-flow drum mix asphalt plants..5. viii LIST OF TABLES Number Page 1.

Supplemental Application Form Concrete, Asphalt Concrete,

Part III: Asphalt Concrete Plant Only. Type of Plant (check one) Batch Continuous Drum Mix counter flow Drum Mix parallel flow Attachment E208-A: Process Information and Flow Diagram Submit a process flow diagram indicating all related equipment, air pollution control equipment and stacks, as applicable.

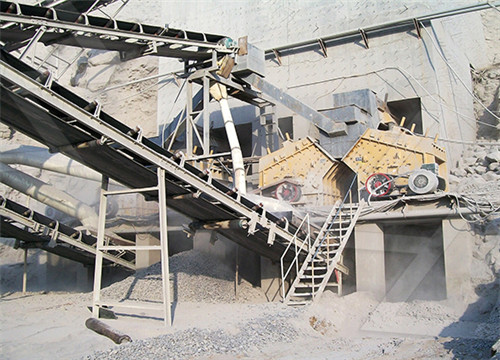

A typical drum asphalt plant (Pavement Tools Consortium, 2010)

Download scientific diagram A typical drum asphalt plant (Pavement Tools Consortium, 2010) from publication: A simulation methodology for online process control of hot mix asphalt (HMA

Asphalt Production PID EdrawMax Templates

2021年3月17日A Process Flow Diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details like piping or designation. Typically, process flow diagrams of a

11.2 Asphalt Roofing US EPA

dry looper, the felt may pass into the spray section of the saturator (not used in all plants), where asphalt at 205 to 250°C (400 to 480°F) is sprayed onto one side of the felt through several nozzles. In Asphalt blowing process flow diagram.1,4 (SCC = Source Classification Code) 11.2-2 EMISSION FACTORS 1/95. Figure 11.2-2.

Schematic representation of the wet and dry process in a

Download scientific diagram Schematic representation of the wet and dry process in a discontinuous asphalt plant. Valves (a, b, d) open ¼ wet process; valves (c, e) open ¼ dry process

Asphalt Production PFD Free Asphalt Production PFD

Asphalt Production PFD Template A simple PFD showing the process of YSG type modified asphalt production clearly. It will make you instantly productive when making similar PFDs. Download Template: Get EdrawMax Now! Free Download Share Template: Popular Latest Flowchart Process Flowchart Workflow BPMN Cross-Functional

General process flow diagram for batch mix asphalt plants

Process Fugitive Emissions Open Dust Emissions BURNER 3-05-002-01, -51, TRUCK LOAD-OUT (SCC 3-05-002-14) ASPHALT CEMENT STORAGE (SCC3-os-OD2.os, .07. (SCC 305-002-12) General process flow diagram for batch mix asphalt plants (source classification codes in parentheses). Author:

Research progresses of fibers in asphalt and cement materials: A

2023年3月2日Natural plant fiber is a multi-layered thick-walled cavity structure as shown in Fig. 2.The structure consists of primary wall, secondary wall and cavity, where the thickness of the primary wall is small, and the secondary wall consists of three layers, i.e., S 1, S 2 and S 3, which are thicker and each layer has a long chain of helical cellulose

id/asphalt plant process diagram.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.

Asphalt Plant Permitting: An Ongoing Quest for Compliance

2022年5月17日Plant layout. Emissions points of equipment Site plan Flow diagram Fuel type (s) Estimated emission levels. Noise levels depending on location. Height restrictions (if applicable) Safety plan...

Chapter 2 Asphalt and Asphalt Paving Materials APAI

The black cementing agent known as asphalt has been used for road construction for centuries. Although there are natural deposits of asphalt, or rock asphalt, most used today is produced by the oil refining industry. Asphalt is a constituent of most petroleums and is isolated through the refining process of distillation. (See Figure 2-1.)

Asphalt Plant Safety Health and Safety Authority

Simplified Basic Process of Making Asphalt Bitumen is stored in one or more tanks and is kept at a temperature in excess of 150 0 Centigrade and transported into the Asphalt process through a pipeline Raw materials are held in hoppers or storage bins which are transported by conveyor into a dryer