lead and zinc ore crushing and grinding

BACKGROUND REPORT AP-42 SECTION 12.18 LEAD

LEAD-BEARING ORE CRUSHING AND GRINDING Prepared for U.S. Environmental Protection Agency OAQPS/TSD/EIB Research Triangle Park, NC 27711 Updated March

AP42 12.18 Leadbearing Ore Crushing and Grinding

12.18 Leadbearing Ore Crushing And Grinding 12.18.1 General1 Leadbearing ore is mined from underground or open pit mines. After extraction, the ore is processed by

Galena Sphalerite FlotationSeparation Method

2016年4月23日The size of crushing equipment will depend on the size of ore and tonnage of material delivered to the crusher. GRINDING Lead

How to Process Lead-Zinc Ore by Gravity and Froth Flotation?

Mineral Testing of Lead-Zinc OreLead-Zinc Ore Beneficiation FlowFeatures and Case of Lead-Zinc Ore Gravity SeparationFeatures and Case of Lead-Zinc Ore Flotation

Flotation features of lead-zinc oreProcess advantages 1. Good separation effect and high quality for refractory lead-zinc ores; 2. Flotation method can realize the separation of lead and zinc, improving the content of lead and zinc; 3. Flotation process is energy-saving and high-yield. The energy-saving can reach 60% anLead-zinc ore flotation in Peru Free Customized DesignFtmmachinery lead-zinc ore flotation case in Peru The main minerals of a lead-zinc mine in Peru are 5.1% galena and 15.0% sphalerite. The ores are characterized by a high lead-zinc oxidation rate (10-30%) and a large amount of easy-floating pyrite (20-30%). The mineral content is as fol在ftmmachinery上查看更多信息

Lead Zinc Mining SolutionEquipment Mineral

Generally, lead zinc flotation processing plant main process divided into three stages: crushing and screening grinding flotation separation- concentate and dewatering. 1.CrushingScreening: The crushing

How to Process Low-Grade Lead Zinc Ore by Flotation

2016年4月27日Lead and Zinc Pb-Zn Separation Process Circuit Primary Washing and Crushing A Drag or Conveyor is used to bring the dump material to a Revolving Trommel Screen which discards all plus 2″

Lead-zinc ore crushing and grinding process mpl Ultrafine

2022年6月10日In the crushing process, the three-stage closed-circuit crushing is a more modern method suitable for the crushing of high-hardness lead-zinc ore, which can

Lead and Zinc ore dressing Mining And Mineral Processing

2021年3月12日Lead and Zinc ore dressing flow chart The flotation process of zinc oxide ore as follows: flotation process of zinc oxide ore A. Grinding argillaceous zinc oxide

Effect of a Crushing Technique on Lead–Zinc Ore Processing

2018年4月16日Effect of a Crushing Technique on Lead–Zinc Ore Processing Performance N. G. Barnov, A. A. Lavrinenko, O. G. LusinyanV. V. Chikhladze Journal

BACKGROUND REPORT AP-42 SECTION 12.18 LEAD-BEARING

LEAD-BEARING ORE CRUSHING AND GRINDING Prepared for U.S. Environmental Protection Agency OAQPS/TSD/EIB Research Triangle Park, NC 27711 Updated March 2007 Due to ore body formations, lead and zinc ores are normally deep mined (underground), whereas copper ores are mined in open pits. Lead, zinc, copper, and

Utilization of lead ions to improve surface hydrophobicity and

Zinc oxide minerals often coexist with lead minerals in ores, and lead ions (Pb 2+) dissolve from lead minerals during grinding and slurry stirring.These dissolved Pb 2+ ions affect the surface properties of zinc oxide minerals and the interaction between the mineral surface and flotation reagents, causing a change of the flotation behavior of the zinc oxide minerals.

(PDF) Comminution Effects on Mineral-Grade

2020年10月9日in mineral processing, the crushing and grinding of extracted ore are crucial operations for the following separation steps. Comminution is the most energy-consuming operation in mining, and

Lead and Zinc Energy

6.1.2.1 Lead and Zinc Ore Milling Treatment of lead and zinc ores begins with milling. Milling is a multi-stage crushing and grinding operation. It involves coarse crushing followed by wet grinding. Crushing is usually a dry operation that utilizes water sprays to control dust. Primary crushing is often performed at

Effect of a Crushing Technique on Lead–Zinc Ore Processing Performance

2018年4月16日Under consideration is the influence of various crushing techniques on the particle-size distribution and selectivity of dissociation of basic mineral components in the composition of Dalnegorsk complex ore under pretreatment. Distribution of basic elements per size grades is determined in crushing feed and in products of magnetic separation

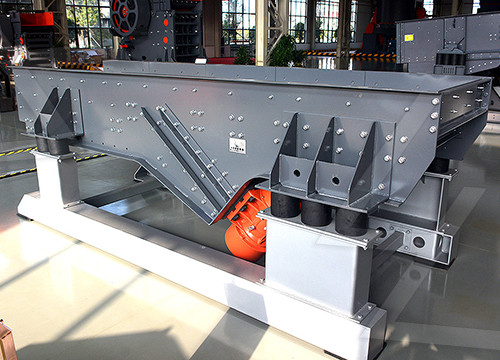

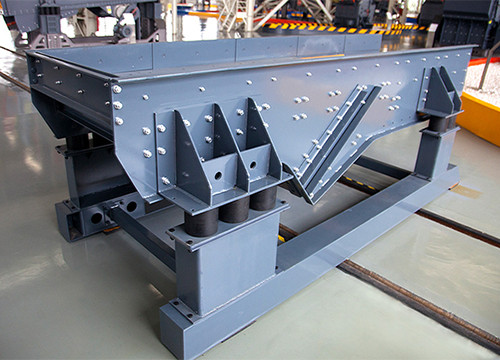

What Ore Processing Equipment Is Used for Lead Zinc

2022年11月20日The crushing and grinding stage of lead-zinc ore can be divided into two parts: crushing and screening and grinding and classification. This stage determines the selected material particle size of lead-zinc ore, which is related to the smooth progress of subsequent lead-zinc ore beneficiation.

Lead-zinc ore processing

Lead-zinc ore introduction:. The processing technology of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation.In the process of crushing, the three-stage closed-circuit crushing is modern and suitable for the crushing of high-hardness lead-zinc ore, which can complete the work of ore crushing and partial

LeadZinc Ore Processing Prominer (Shanghai)

General processing technologies for copper ore are summarized as below: I. Physical processing technology: Crushinggrinding solution Flotation process Flotation process is mostly used for lead and zinc beneficiation.

HPT Cone Crusher Popular in Metallic Mining Industry

When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

12.18 Leadbearing Ore Crushing And Grinding Epa.gov

After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease of some 15,000 Mg (16,500 tons) from 1990 production. Except for mines in Missouri, lead ore is closely interrelated with zinc and silver. Lead ores

Effect of Microwave Pretreatment on Grindability of Lead-Zinc Ore

2021年7月16日The influence of microwave pretreatment on grindability of lead-zinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below 0.074 mm, energy consumption, and other indexes of grinding products before and after microwave pretreatment in the ball milling process.

How to Process Oxidized Lead-Zinc Ore by Flotation

2016年4月27日The final lead and zinc concentrates are pumped by concentrate pumps to Thickeners for dewatering prior filtration. The thickener underflow at approximately 50% solids is pumped to a Disc Filter by means of a Diaphragm pump. The filter cakes pass to concentrate bins for storage. Sampling

Crushing, Grinding and Concentration of the Ore Class Notes

2023年2月16日(1) Crushing and Grinding of the Ore. The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders. These pieces are then reduced to fine powder with the help of a ball mill or stamp mill. This process is called pulverisation. (2) Concentration of Ore or Ore Benefaction

BACKGROUND REPORT AP-42 SECTION 12.18 LEAD-BEARING

LEAD-BEARING ORE CRUSHING AND GRINDING Prepared for U.S. Environmental Protection Agency OAQPS/TSD/EIB Research Triangle Park, NC 27711 Updated March 2007 Due to ore body formations, lead and zinc ores are normally deep mined (underground), whereas copper ores are mined in open pits. Lead, zinc, copper, and

Utilization of lead ions to improve surface hydrophobicity and

Zinc oxide minerals often coexist with lead minerals in ores, and lead ions (Pb 2+) dissolve from lead minerals during grinding and slurry stirring.These dissolved Pb 2+ ions affect the surface properties of zinc oxide minerals and the interaction between the mineral surface and flotation reagents, causing a change of the flotation behavior of the zinc oxide minerals.

(PDF) Comminution Effects on Mineral-Grade

2020年10月9日A preliminary study was performed in order to understand the crushing behavior under different comminution forces of a high-grade mixed Zn-Pb sulfide ore sample, collected in a...

Effect of a Crushing Technique on Lead–Zinc Ore Processing Performance

2018年4月16日Under consideration is the influence of various crushing techniques on the particle-size distribution and selectivity of dissociation of basic mineral components in the composition of Dalnegorsk complex ore under pretreatment. Distribution of basic elements per size grades is determined in crushing feed and in products of magnetic separation

Lead and Zinc Energy

6.1.2 Lead and Zinc Ore beneficiation Due to low zinc content, run-of-mine zinc-bearing ores must be concentrated before smelting and refining. Beneficiation, which usually occurs at the mine, consists of crushing, grinding, and flotation to produce concentrates of 50 to 60 percent zinc. Lead ore also requires processing to

AP42 12.18 Leadbearing Ore Crushing and Grinding

12.18 Leadbearing Ore Crushing And Grinding 12.18.1 General1 Leadbearing ore is mined from underground or open pit mines. After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease of some 15,000

LEAD-ZINC ORE CRUSHINGPROCESSING Linkedin

2015年9月18日Lead and zinc ore is the metal-rich mineral elements such as lead and zinc, blue gray, hardness 1.5, it is the most soft metals, lead is one of the earlier extracted in history, lead and zinc are

Lead-zinc ore processing

Lead-zinc ore introduction:. The processing technology of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation.In the process of crushing, the three-stage closed-circuit crushing is modern and suitable for the crushing of high-hardness lead-zinc ore, which can complete the work of ore crushing and partial

12.18 Leadbearing Ore Crushing And Grinding Epa.gov

After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease of some 15,000 Mg (16,500 tons) from 1990 production. Except for mines in Missouri, lead ore is closely interrelated with zinc and silver. Lead ores

4 Step Beneficiation Process of Lead-Zinc Ore Xinhai

2022年10月8日The separation of lead-zinc ore is mainly flotation, and its beneficiation process can generally be divided into four parts, namely: crushing and screening stage, grinding stage, separation stage and dehydration and concentration stage. The following are the detailed beneficiation process of lead-zinc ore.

Crushing, Grinding and Concentration of the Ore

2023年2月16日(1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders. These pieces are then reduced to fine powder with

Effect of Microwave Pretreatment on Grindability of Lead-Zinc Ore

2021年7月16日The influence of microwave pretreatment on grindability of lead-zinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below 0.074 mm, energy consumption, and other indexes of grinding products before and after microwave pretreatment in the ball milling process.

HPT Cone Crusher Popular in Metallic Mining Industry

When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc Mine

2023年3月4日The lead–zinc mine Bleiberg-Kreuth located in the Austrian federal state of Carinthia has had a long mining history, spanning from the early 14th century to the 1990s. The mining and processing activities undertaken over the centuries and, consequently, the composition of the waste rock material changed throughout this period.