putting up a clinker grinding cement plant

Set-Up Mini Clinker Grinding Unit 5 to 25 TPH YouTube

2020年12月30日Set-Up Mini Clinker Grinding Unit 5 to 25 TPH Ball Mill Close Circuit Cementpdm 44.1K subscribers Join Subscribe 314 Share 14K views 2 years ago #cementplant #cement #cementpdm Part-3 How...

CLINKER GRINDING IN CEMENT PRODUCTION Energosteel

2019年2月21日Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone

Differences between Clinker Grinding Plant and Cement Plant

2023年2月13日Clinker grinding plants have a simpler production process, lower capital costs, and lower maintenance costs, making them more suitable for small-scale or

How to set up a cement clinker grinding unit?

2023年2月22日The whole workflow of the cement grinding plant is as follows: the cement clinker, gypsum, and mixture in the cement silo are mixed by the belt conveyor

How to Start a Cement Factory AGICO Cement Plant

1. Clarify Your Production Scale and Cement Type. The first thing to do when you are planning to start a cement factory is to determine which type of cement you are going to

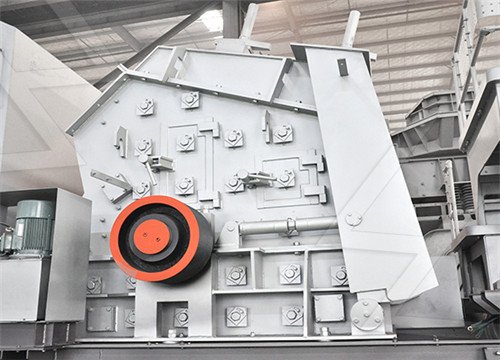

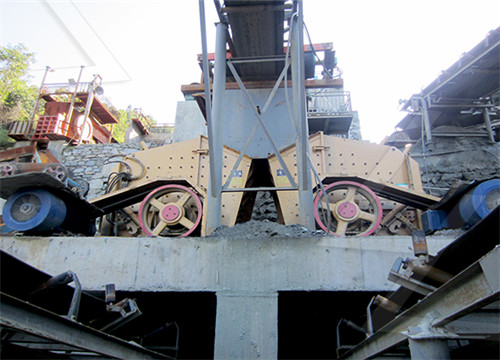

Cement Grinding Unit Cement Grinding Plant

Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 3.2 ×13m

Cement clinker Wikipedia

Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature. The products of the chemical reaction aggregate together at their sintering temperature, about 1,450

Breakthrough in Clinker Grinding Massachusetts Institute

2012年11月8日Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The European Cement Research Academy (ECRA) estimates that up to 70% of the power consumed in cement production is for material size reduction. Increasing the efficiency of particle size

World Cement GrindingMilling Q&A World Cement

2022年2月18日Along with the increasing demand for low clinker cements or high early strength cement types, the installation of the polysius ® booster mill is a highly energy-efficient solution for achieving the necessary cement quality even at existing cement grinding plants. It is a horizontal agitated bead mill based on a modular and very

Clinker size and cement grinding GCP Applied Technologies

2021年2月8日As a general rule, there should be less than 25% of clinker that is below 1mm in size. Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed. However, one drawback with this approach is that

sbm/sbm putting up a clinker grinding cement plant.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Cement Grinding Plant / Grinding Unit AGICO

With a strong R&D team, experienced engineers, and first-class technical services, we aim to provide users with the most advanced and optimized cement production solutions. The main task of the cement grinding

CLINKER GRINDING IN CEMENT PRODUCTION

2019年2月21日Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules

Clinker Plant Cement Plant Cement Equipment For Clinker

2019年12月2日Cyclone preheater: preheater in cement plant use suspension preheat to complete the raw meal preheating and partial precalcining. The cyclone preheater reduces the energy consumption of the clinker plant, also reduces the occupied area.

Cement Clinker Grinding Plant(Crusher-Ball Mill-Powder

2021年12月8日🔥Cement Grinding Plant: 👉Pls click web for latest price: https://fte-china/pro/cement_grinding_station.html?Yzl👉Whatsapp/wechat:

Cement clinker Wikipedia

Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature. The products of the chemical reaction aggregate together at their sintering temperature, about 1,450

Emission Estimation Technique Manual UNITAR

Cement Manufacturing 3 Emission Source for Wet and Dry Process General (A) Kiln (L) Clinker grinding (B) Raw material unloading (M) Cement silos (C) Raw material piles (N) Cement load out (D) Primary crushing (O) Raw mill feed belt (E) Secondary crushing (P) Raw mill weigh hopper (F) Screening (Q) Raw mill air separator Particulate Matter

Greenfield standalone cement grinding unit TNPCB

The Cement Grinding Plant comprises the following preparation, processing and handling units: Clinker unloading, handling, storing and retrieval system. Gypsum unloading, handling, storing and retrieval system. Clinker proportioning and feeding Gypsum storage, proportioning and feeding. Clinker and Gypsum Grinding. Fly ash classification,

Buildings Free Full-Text Study on the Effect of Supplementary

2023年3月6日In the preparation of ready-mixed concrete, it is inevitable to produce waste fresh concrete (WFC). An efficient, low-cost and environmentally friendly recycling scheme is the key to WFC recycling. In this work, we directly added some unhardened WFC to fresh concrete to prepare recycled fresh concrete (RFC); on this basis, fly ash (FA) and nano

Breakthrough in Clinker Grinding Massachusetts Institute

2012年11月8日Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The European Cement Research Academy (ECRA) estimates that up to 70% of the power consumed in cement production is for material size reduction. Increasing the efficiency of particle size

World Cement GrindingMilling Q&A World Cement

2022年2月18日Along with the increasing demand for low clinker cements or high early strength cement types, the installation of the polysius ® booster mill is a highly energy-efficient solution for achieving the necessary cement quality even at existing cement grinding plants. It is a horizontal agitated bead mill based on a modular and very

Clinker size and cement grinding GCP Applied Technologies

2021年2月8日As a general rule, there should be less than 25% of clinker that is below 1mm in size. Coarse clinker is more of an issue for ball mills. Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed.

Cement clinker Wikipedia

Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature. The products of the chemical reaction aggregate together at their sintering temperature, about 1,450

sbm/sbm putting up a clinker grinding cement plant.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Cement Grinding Plant / Grinding Unit AGICO

With a strong R&D team, experienced engineers, and first-class technical services, we aim to provide users with the most advanced and optimized cement production solutions. The main task of the cement grinding

Cement Grinding Plant Overview Cement Grinding Unit AGICO Cement

2019年10月11日The whole workflow of the cement grinding plant is as follows: the cement clinker, gypsum, and mixture in the cement silo are mixed by the belt conveyor in a certain proportion and transported to the cement roller press, cement mill or group of them for grinding. The cement is ground by the cement mill to the required particle size.

Cement Clinker Grinding Plant(Crusher-Ball Mill-Powder

2021年12月8日🔥Cement Grinding Plant: 👉Pls click web for latest price: https://fte-china/pro/cement_grinding_station.html?Yzl👉Whatsapp/wechat:

U.S. Portland Cement Industry: Plant Information Summary

2010 survey, Essroc Cement Co.’s Essexville grinding plant ceased operations and Essroc’s grinding-only facility in Nazareth, PA was combined with their clinker-producing plant bringing the number of grinding-only plants to seven. U.S. cement manufacturing is primarily a fossil fuel fired industry with 91.7% of all plants using coal,

Greenfield standalone cement grinding unit TNPCB

The Cement Grinding Plant comprises the following preparation, processing and handling units: Clinker unloading, handling, storing and retrieval system. Gypsum unloading, handling, storing and retrieval system. Clinker proportioning and feeding Gypsum storage, proportioning and feeding. Clinker and Gypsum Grinding. Fly ash classification,

Emission Estimation Technique Manual UNITAR

Cement Manufacturing 3 Emission Source for Wet and Dry Process General (A) Kiln (L) Clinker grinding (B) Raw material unloading (M) Cement silos (C) Raw material piles (N) Cement load out (D) Primary crushing (O) Raw mill feed belt (E) Secondary crushing (P) Raw mill weigh hopper (F) Screening (Q) Raw mill air separator Particulate Matter

Buildings Free Full-Text Study on the Effect of Supplementary

2023年3月6日In the preparation of ready-mixed concrete, it is inevitable to produce waste fresh concrete (WFC). An efficient, low-cost and environmentally friendly recycling scheme is the key to WFC recycling. In this work, we directly added some unhardened WFC to fresh concrete to prepare recycled fresh concrete (RFC); on this basis, fly ash (FA) and nano