layout stone crusher plant

The best way to Design a Stone Crusher Plant Layout

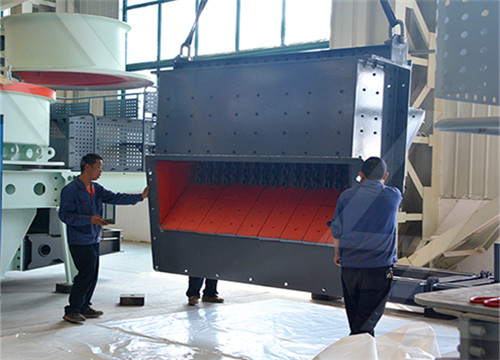

2022年7月19日A stone crusher plant designer follows three steps to generate the layout: • Process design • Equipment selection • Layout The primary design

Crushing Plant FlowsheetDesign-Layout Mineral Processing

Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement. The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant a在911metallurgist上查看更多信息预计阅读时间:13 分钟文件大小: 2MB

Stone crusher plant design Henan Deya Machinery Co., Ltd.

2022年4月19日The crusher plant design should consider the multi-stage crushing principle, normally it includes primary crushing, secondary crushing, tertiary crushing,

Crushing Plant Design and Layout Considerations JXSC Mine

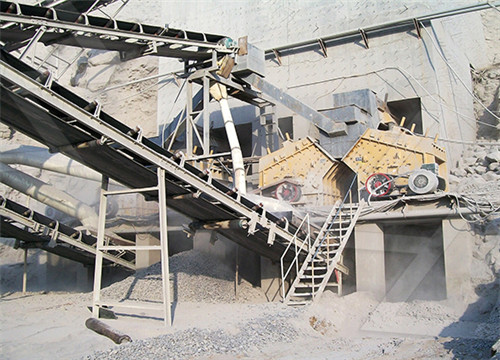

2 Considerations of crushing plant layout 2.1 Two stages of crushing flow sheet The crushed product obtained by the two-stage open crushing process has a coarse particle size and is only used in a simple small ore

Environmental GUIDELINE ON STONE CRUSHING plant

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt

Crusher Plant MineralAggregate Processing JXSC Mine

Crusher plant features 1. Automatic operation. There is hardly any need of manual operation except for start-up, shutdown, and routine maintenance. 2. High production efficiency at low cost, uniform particle size, and good

10 Types of Stone Crusher Plants Price and More for Sale

The stone crusher plant is used for producing sand, rock and stone for construction, highway, railway and other applications. Fote Heavy Machinery, with 40 years of

Reasonable Stone Crusher Plant AIMIX GROUP

AIM938JC80 stone jaw crusher plant Type: AIM938JC80 Transportation length (mm): 12600 Transportation width (mm): 2600 Transportation height (mm): 3870 Weight (t): 39 Jaw crusher model: JC80 Max feed size

The best way to Design a Stone Crusher Plant Layout

2022年7月19日A stone crusher plant designer follows three steps to generate the layout: • Process design • Equipment selection • Layout The primary design parameters driving the crushing plant and configuration includes the subsequent: • Capital cost • Production requirements • Maintenance requirements • Ore characteristics • Safety and

Mineral Processing Plant Design University Of Technology,

Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. The fundamental goal for the design of a crushing plant is

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

Environmental GUIDELINE ON STONE CRUSHING plant

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt boulders. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for

Stone crusher plant Henan Deya Machinery Co., Ltd.

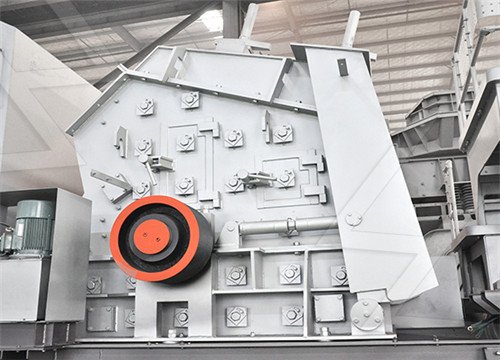

2022年7月5日2.1 Primary crushing stage. 2.1.1. Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers. The impact crusher, as a primary crusher, is only suitable for medium to soft rocks, such as limestone, and thus its use is limited. Large jaw crushers with a maximum feed length of

P&Q University Lesson 2- Site SelectionPlant Design

2019年8月5日Natural aggregates are composed of crushed stone and sand and gravel. Igneous, sedimentary, and metamorphic rocks are used to make crushed stone and are extracted by open pit and underground mining techniques. Sand and gravel can be mined by open pit, cut and backfill, or dragline methods.

KINGSON CRUSHER JAW CONE Layout

2019年3月29日KINGSON CRUSHER JAW CONE Layout YouTube Kingson Crusher Manufacturer of All kings of Stone Crushing Equipment, Accessories and Turnkey Plants including JAW CRUSHER, CONE...

CrushingScreening Plant Design Factors Mineral Processing

2016年4月14日Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or

Reasonable Stone Crusher Plant AIMIX GROUP

AIM938JC80 stone jaw crusher plant Type: AIM938JC80 Transportation length (mm): 12600 Transportation width (mm): 2600 Transportation height (mm): 3870 Weight (t): 39 Jaw crusher model: JC80 Max feed size

Machine Foundation Design -Stone Crusher Plant Foundations

2021年7月11日1)I would prefer to combine the foundations of crusher +retaining wall+ found. of feeder. But the use of Vibration Isolation for the Crusher found. should be an option.. 2) Dynamic analysis is better . Otherwise follow the rule of thumbs.. ( reduce the safe soil bearing stress to 60%,provide weight of ftg 3 times of vibrating wt..

11.19.1 Sand And Gravel Processing US EPA

undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be

HSE Quarries Safe operation and use of mobile jaw crushers

This should detail the procedures to follow in the event of a crusher stalling. These instructions should include the following: Isolation of motive power to the crusher and associated plant...

The best way to Design a Stone Crusher Plant Layout

2022年7月19日A stone crusher plant designer follows three steps to generate the layout: • Process design • Equipment selection • Layout The primary design parameters driving the crushing plant and configuration includes the subsequent: • Capital cost • Production requirements • Maintenance requirements • Ore characteristics • Safety and

Mineral Processing Plant Design University Of Technology,

Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. The fundamental goal for the design of a crushing plant is

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

Stone crusher plant Henan Deya Machinery Co., Ltd.

2022年7月5日2.1 Primary crushing stage. 2.1.1. Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers. The impact crusher, as a primary crusher, is only suitable for medium to soft rocks, such as limestone, and thus its use is limited. Large jaw crushers with a maximum feed length of

Environmental GUIDELINE ON STONE CRUSHING plant

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt boulders. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for

The way to Design a Stone Crusher Plant Layout Philippines

2022年9月7日The essential objective of designing a stone crusher plant layout is to make certain the installation of the appliance meets the required production requirements, complies with environmental regulations, and operates in a competitive cost. You should consider these industry trends before planning the layout.

ROCK CRUSHING PLANT APPLICATIONS ADVICE Oklahoma

In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles. It may also E. Select Chapter 11 and download Section 11.19.2 for “Crushed Stone Processing.” F. For engines, select Chapter 3 and download Section 3.3 for diesel engines

11.19.1 Sand And Gravel Processing US EPA

undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be

HSE Quarries Safe operation and use of mobile jaw crushers

This should detail the procedures to follow in the event of a crusher stalling. These instructions should include the following: Isolation of motive power to the crusher and associated plant...

Stone Crusher Project Report, Stone Quarry Crushing Plant Design

Here will show you how to manage a stone crushing plant in quarry operation. The stone crusher project report deals with the production and use of stones for producing manufactured sand, which is defined as aggregate material less than 4 mm, processed from crushed rock or gravel, intended for construction use. The motivation for this project is

Primary Crusher an overview ScienceDirect Topics

The broken stone is dumped into a primary crusher where the large rock fragments are broken into smaller sizes. there is still room for improvement of the overall plant layout and construction, e.g. crushing plant, silo discharge system, train unloading system, etc. One of the most obvious ways to improve the overall design of such systems