ore processing open pit molybdenite mining equipment

UNITED STATES Climax Molybdenum A Freeport-McMoRan

The Climax ore body is a porphyry molybdenum deposit, with molybdenite as the primary sulfide mineral. The Climax open-pit mine includes a 25,000 metric ton-per-day mill

Open-Pit Mining Method and Process Epiroc US

Molybdenum Mining IMOA

Co-product mines, where the commercial viability of the mine requires that both molybdenite and copper-bearing minerals be recovered. If the ore lies close to the surface, open cast pit technology is employed. Here the

Cerro Verde Copper-Molybdenum Mine Mining Technology

2014年4月6日Cerro Verde Copper Mine is an open-pit copper and molybdenum mining complex located 32km south-west of Arequipa in Peru. The mining concession spreads

How Is Molybdenum Mined And Processed? Refractory Metals

If the ore is near the surface, open-pit mining technology is used to dig overburden to expose the ore body for easy mining. If the ore is located deep underground, underground block caving technology is adopted.

Molybdenum Mining Equipment for Sale, Mobile Crusher for

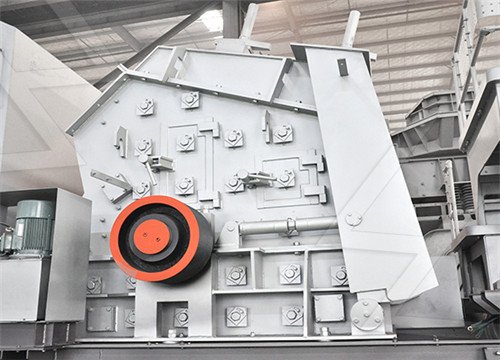

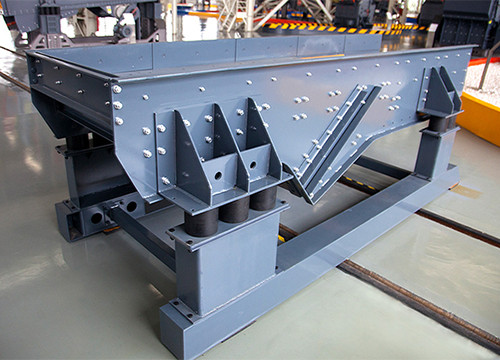

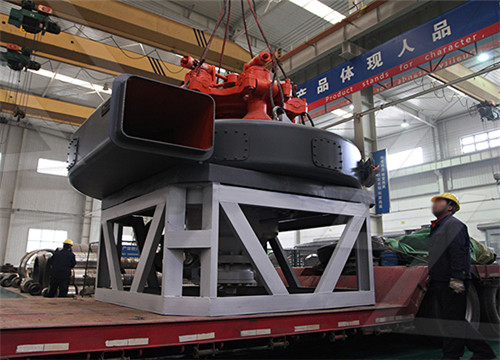

Mobile crusher equipment for molybdenum open pit mining can be equipped jaw crusher, impact crusher, cone crusher, screening machine and belt conveyor for various crushing

MINING Equipment List Mining Tools Names + Underground

2019年6月30日1.7 Mining drill. 1.8 Underground Loader. 1.9 Crane lift. 1.10 Shotcrete machine. 1.11 Longwall Mining. 2 Heavy mining machinery list. 3 Underground mining equipment. 4 Mining machinery names. 4.1

Molybdenite mining crushing beneficiation MiningQuarry Plant

Molybdenum beneficiation plant and processing equipment for sale. Molybdenum Ore Crusher for molybdenum mining processing. Our company also offers a complete

Open-Pit Mining Methods MetallurgistMineral Processing

2017年4月9日Open-pit mining methods are applicable to mining ore deposits that apex at or near the surface. If the deposit apexes below the surface, the overburden and barren capping overlying the ore must be

Mt. Hope Molybdenum Project, Eureka, Nevada

2015年3月5日Mining and processing of ore at Mt Hope Mt Hope will use a conventional open pit method of mining, involving drilling, blasting, and loading. The ore and wastes will be delivered to the crusher and waste

Climax mine Wikipedia

The method allowed economical extraction of the large low-grade ore deposit. Current mining operations at Climax are via an open-pit. The ore is crushed on-site, and the molybdenite is separated from the waste

Mineral Processing Solutions Westech-inc

With cutting-edge processing technologies, WesTech solutions can render the byproducts of mineral extraction wastewater inert. The byproducts are then reliably contained and made safe for the environment. The processes we employ are effective at keeping groundwater, surface waters, wildlife, and communities protected from tailings dam leaks and

Molybdenum Mining Equipment for Sale, Mobile Crusher for Open Pit Mining

Mobile crusher equipment for molybdenum open pit mining can be equipped jaw crusher, impact crusher, cone crusher, screening machine and belt conveyor for various crushing applications, including primary crushing, secondary crushing and tertiary crushing operation.

Mining Tools in 2022—A Guide to Mining Equipment and Mining

Open pit mining. Open-pit mining is a technique that involves drilling into the earth’s surface to set explosives. These explosions create a large pit for miners to access underlying rocks. This surface mining technique can be used to extract silver. Quarrying. Quarrying is a process in which miners cut blocks of hard stone. Miners will also

MINING Equipment List Mining Tools Names

2019年6月30日1 Mining equipment list 1.1 Dragline excavator 1.2 Excavator shovel 1.3 Bucket-wheel excavator 1.4 Wheel tractor scrapers 1.5 Bulldozer 1.6 Mining Truck 1.7 Mining drill 1.8 Underground Loader 1.9

9.1 DEVELOPMENT PIT SEQUENCING

2016年9月21日and equipment requirements. 9.1.2 Open Pit Ore Mining Rate and Period Surface mining is expected to occur for approximately 12 r15 years following the initial site cleanup, which includes the removal of the previously mined development rock in and around the Yellow Pine

Molybdenite mining crushing beneficiation MiningQuarry

Molybdenum beneficiation plant and processing equipment for sale. Molybdenum Ore Crusher for molybdenum mining processing. Our company also offers a complete molybdenum mining equipment, crushing machine by the molybdenum ore, grinding, sand making and beneficiation equipment. grindind in molybdenite. Molybdenum ore

open pit molybdenite mining equipment molybdenum processing

its crude concentrate often contains scheelite chalcopyrite 0.017% molybdenum the concentrated molybdenite would be subjected to a further step of chemical beneficiation processing.In open pit perovskite mining plant using a $15.00/lb molybdenum price over 24 years of mining and 30 years of mill processing at an 8% discount rate

How to Choose Open-pit Mining Equipment? Mining-pedia

2020年11月6日01 Equipment Choice Order. The selection process of open-pit mining equipment is generally to select the appropriate loading equipment first,and determine the supporting transportation equipment. And then choose drilling equipment. When the main equipment is properly matched, then to confirm the auxiliary equipment.

Open-Pit Mining Methods MetallurgistMineral Processing

2017年4月9日Open-pit mining methods are applicable to mining ore deposits that apex at or near the surface. If the deposit apexes below the surface, the overburden and barren capping overlying the ore must be removed in advance of open-pit mining. The removal of this material is known as stripping.

May 1 Surface Mining Techniques used in the Oil

2016年5月1日Surface mining is defined as the extraction of ore from an open pit or burrow. Surface mining is sometimes known as open-pit, open-cut or open-cast mining and is only commercially viable if the

The mining value chain: A hidden gem McKinsey

2020年10月5日The mining value chain— which includes everything from extracting raw material to delivering products to customers—is the backbone of the industry. Companies that manage their value chain well can establish a significant source of competitive advantage and value creation. By contrast, those that neglect their value chain are likely

Cerro Verde Copper-Molybdenum Mine Mining Technology

2014年4月6日Cerro Verde Copper Mine is an open-pit copper and molybdenum mining complex located 32km south-west of Arequipa in Peru. The mining concession spreads across approximately 157,007 acres (63,538ha), plus 24 acres of owned property and 79 acres of rights-of-way outside the concession region. It is the second biggest copper

Open-Pit Mining Method and Process Epiroc

Open-pit mining technology. Open-pit mining clearly offers a number of economic advantages over underground mining, especially now that mineral-processing technology has advanced to the stage where very low-grade ores can be treated profitably. 100 to 150 years ago, this was not the case, and mining was still much more selective.

Mineral Processing Solutions Westech-inc

With cutting-edge processing technologies, WesTech solutions can render the byproducts of mineral extraction wastewater inert. The byproducts are then reliably contained and made safe for the environment. The processes we employ are effective at keeping groundwater, surface waters, wildlife, and communities protected from tailings dam leaks and

Mining Tools in 2022—A Guide to Mining Equipment and Mining

Open-pit mining is a technique that involves drilling into the earth’s surface to set explosives. These explosions create a large pit for miners to access underlying rocks. This surface mining technique can be used to extract silver. Quarrying. Quarrying is a process in which miners cut blocks of hard stone.

Open-Pit Mining Methods MetallurgistMineral Processing

2017年4月9日Open-pit mining methods are applicable to mining ore deposits that apex at or near the surface. If the deposit apexes below the surface, the overburden and barren capping overlying the ore must be removed in advance of open-pit mining. The removal of this material is known as stripping.

Molybdenum: mining and processing-Metalpedia Asian Metal

Molybdenum: mining and processing; Mining; Molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products. Molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly

How to Choose Open-pit Mining Equipment? Mining-pedia

2020年11月6日01 Equipment Choice Order. The selection process of open-pit mining equipment is generally to select the appropriate loading equipment first,and determine the supporting transportation equipment. And then choose drilling equipment. When the main equipment is properly matched, then to confirm the auxiliary equipment.

9.1 DEVELOPMENT PIT SEQUENCING

2016年9月21日and equipment requirements. 9.1.2 Open Pit Ore Mining Rate and Period Surface mining is expected to occur for approximately 12 r15 years following the initial site cleanup, which includes the removal of the previously mined development rock in and around the Yellow Pine

Molybdenite mining crushing beneficiation MiningQuarry

Molybdenum beneficiation plant and processing equipment for sale. Molybdenum Ore Crusher for molybdenum mining processing. Our company also offers a complete molybdenum mining equipment, crushing machine by the molybdenum ore, grinding, sand making and beneficiation equipment. grindind in molybdenite. Molybdenum ore

Sequential glory hole approach as a new mining method for

2019年9月1日Considering the topographic surface, the ore body described in Fig. 1 and the use of conventional equipment to apply the open pit mining method, it is possible to generate new optimization results. This optimization considers mining costs referring to the operations that use trucks and shovels for the pit development.

Climax mine Wikipedia

The method allowed economical extraction of the large low-grade ore deposit. Current mining operations at Climax are via an open-pit. The ore is crushed on-site, and the molybdenite is separated from the waste material by froth flotation, which mixes pulverized ore into a slurry of air, water, surfactants, and other chemicals.

MetallurgistMineral Processing Engineer

Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophy. The evaluation and prioritization of variables that affect the plant’s performance is the primary function.

Zaldívar Copper Mine Northern Chile Mining Technology

2000年4月3日Ore processing Copper is recovered by heap leaching followed by solvent-extraction and electrowinning to produce high-grade cathode copper. There are four major processing components: A crushing plant reduces the ore size A heap-leach operation dissolves the copper, using chemical and bacteriological agents