good performance impact rock crusher

Impact Crusher an overview ScienceDirect Topics

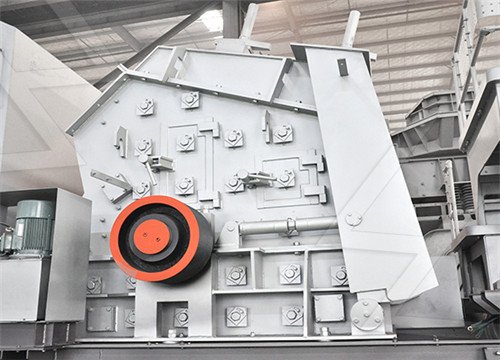

Impact Crusher. The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube

China Good Performance Stone Making Plant

2022年5月14日 Type: Impact Crusher Application: MachineryHardware, ArtCraft, Chemical, Construction, Mineral Industry, Stone Industry Drive: Electric Crushing Style:

(PDF) A performance model for impact crushers

2002年10月1日 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed

Impact Crusher Eastman Rock Crusher

Capacity. 1-500t/h. Output Size. 10-80mm. Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

The Top Rock Crusher Brands Mellott

2020年5月20日 Looking for a rock crusher? These 8 rock crusher brands are worth considering. Contact. Email Form. Support. 855.554.1606 They offer “mining jaw

6 Granite Crushers for Efficient Granite Crushing Fote

2023年2月28日 The six best-selling granite stone crushers are jaw crusher, cone crusher, impact crusher, sand making machine, mobile crusher, and portable crusher. This article

Rock Crusher JawCone Rock Crushing

Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry, and so on. PE400-600-jaw-crusher.

sbm/sbm newest and best performance stone impact

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Impact crushers high-quality impactors Metso Outotec

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be crushed. Disadvantages: The structure and maintenance are more complicated, the body is high, and the price is expensive. 3. Impact Crusher.

Impact Crusher Eastman Rock Crusher

Capacity. 1-500t/h. Output Size. 10-80mm. Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Applications. widely utilized in aggregate, mining, energy, brick and so

RM 100GO! Tracked Impact Crusher RUBBLE MASTER

The RM 100GO! tracked impact crusher weighs 75,000lbs with a top capacity of up to 275 TPH. we’ve designed and manufactured our crushers to deliver best-in-class performance without sacrificing mobility. Secondary crushing after a mobile jaw crusher The RM 100GO! tracked impact crusher processes 8" basalt rock after a jaw crusher

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

crusher/sbm best mining crushing machinery installation

Pilot Crushtec is South Africa 's leading supplier of Mining Equipment in South Africa including mobile and semi mobile crushing,screening,recycling,sand washing. Sandstone Crushing Machine Supplier,Mobile Crusher for Our engineers will help you choose the most suitable equipment,and provide training service about installation and operation for

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

China HongXing Machinery Is Leading the Crushing Trend

Impact Rock Crusher—Ideal Aggregates Making Machine Published : March 04th,2020 Impact crusher can crush aggregates with excellent granularity because of flexible and variable adjustment methods, making the diameter of final aggregates that can be produced reach 0-5mm, 5-10mm, 10

Impact crushers and impact mills with a

Impact crusherimpact mill. Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and

Vertical Shaft Impact Crusher AF Minerals Equipment

Vertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete aggregate and especially for the sand making and road paving. VSI and GS series crushers provide unbeatable performance in secondary, tertiary, quaternary, and shape. VSI Crusher

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be crushed. Disadvantages: The structure and maintenance are more complicated, the body is high, and the price is expensive. 3. Impact Crusher.

The Top Rock Crusher Brands Mellott

2020年5月20日 Looking for a rock crusher? These 8 rock crusher brands are worth considering. Contact. Email Form. Support. 855.554.1606 They offer “mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for If you’re looking for guidance into selecting and servicing a machine that will be the best

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

Fixed Crusher is a stone crusher equipment

There are many types of crushers, including some star products like hydraulic cone crusher, fixed jaw crusher, rock jaw crusher, impact stone crusher, etc. In addition, mpl Machinery is known as sophisticated

Rock Crushers Gold Prospecting Mining

The average miner can instead purchase a CrazyCrusher manual rock crusher or an electric or gas powered rock crusher and get the gold out in smaller batches. Crushing rock to recover gold can be easier, faster, and

crusher/sbm best mining crushing machinery installation

Pilot Crushtec is South Africa 's leading supplier of Mining Equipment in South Africa including mobile and semi mobile crushing,screening,recycling,sand washing. Sandstone Crushing Machine Supplier,Mobile Crusher for Our engineers will help you choose the most suitable equipment,and provide training service about installation and operation for