impact crusher propelled-impact crusher working technical details

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists

Impact Crusher Prominer (Shanghai) Mining Technology

Impact Crusher Application Field. It is suitable for industrial sectors such as metallurgy, mining, cement, chemical industry, refractory materials and ceramics, as well as areas

Impact Crusher Sanme

Working Principle: The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a

Impact crusher structure, working principle and features

Impact Crusher StructureImpact Crusher Working PrincipleImpact Crusher Features

1.5.1 Two rotor reversal rotation impact crusher (Figure 2 a). The two rotors move in opposite directions, equivalent to two parallel configurations of single-rotor impact crushers in parallel. The two rotors form separate crushing cavities with the impact plate for split-cavity crushing. This type of crusher has high production capacity and can cr...

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As

Impact Crusher Eastman Rock Crusher

Capacity. 1-500t/h. Output Size. 10-80mm. Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Applications. widely utilized in aggregate, mining, energy, brick and so

The working principle and performance of impact crusher

The impact crusher has the characteristics of high output, low energy consumption and spare parts consumption, and high crushing efficiency. It is the first choice for ore

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

Impact Crusher Mining, Crushing, Grinding, Beneficiation

2012年8月4日 Kefid impact crusher have three types: PF Impact Crusher, Primary Impact Crusher, Hydraulic Impact Crusher. They are widely used in building materials, cement

mill/sbm impact crusher working technical details.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Impact Crushers Secondary McLanahan

The NGS Impactor represents the next generation secondary Impact Crusher. Still unmatched in the industry, the NGS Impactor is engineered to bring more profitability to aggregate and mineral processing operations. Developed to mimic the productivity of its predecessor, the Impact II, this impactor generates a better, highly cubical product while

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

(PDF) NP Series Impact Crushers Hernanda Basyir

NP series of impact crushers enable to achieve a higher reduction with fewer crushing stages, lowering your capital costs and saving energy. Stationary : Primary NP1415 Impact Crusher fully hydraulic equipped. To get process benefits Very high reduction ratio. Very good cubical shape to meet asphalt and concrete product specifications for

The Practical Advantages of Impact Crusher CSDN博客

2019年9月22日 With the crusher research and development work gained more and more technology results, the impact crusher application field continues to make new technological achievements,and plays an important role in RD and production of new materials work.

Github

sbm impact crusher working principle pptHow does a Gyratory Crusher Works Mineral Processing. In this video we will see what are the basic features of a Gyratory Crushers.Gyrat

Technical Specification Document Of Crusher Stone

2003年4月6日 Aug 16, 2011 Technical Specification Contract Document document sample parts rubber crumbs (CA 04.06.03(d)(i)) to 2 parts crusher dust Vibrating Feeder Standards,Vibrating Feeder Technical Specification

mill/sbm impact crusher working technical details.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

(PDF) A performance model for impact crushers

2002年10月1日 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an internal moving element (mantle) [9,10].

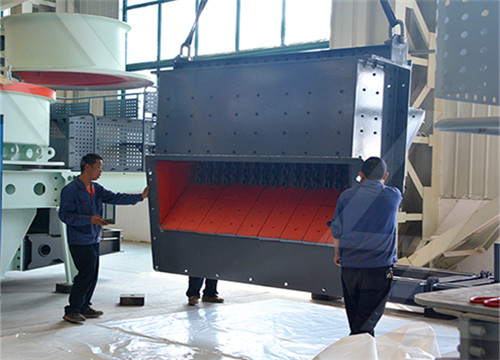

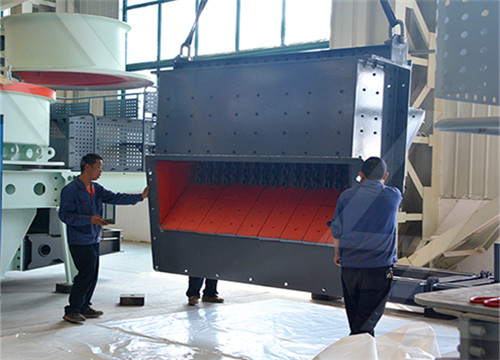

China Impact Crusher factory and suppliers Ascend

2021年12月24日 1.Heavy-duty rotor design, as well as strict detection means, to ensure high-quality rotor. Rotor is the “heart” of crusher. It is also a part of impact crusher which has strict acceptance. It plays a vital role in the work. 2. Unique structural design, the finished product is cubic, tension-free and crack-free, with good grain shape.

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

2011年5月10日 An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft. Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotor.

Impact Crusher JXSC Machine

2023年2月13日 Advantages. 【 What is Impact Crusher 】Impact crusher (impact break) is an ideal crushing machine for medium hardness materials, it can produce a more uniform particle shape (cubical) final product compared with the hammer crusher. Impact crushers are widely used in the aggregate industry (cement, asphalt, sandgravel), owing to high

Hammer crusher All industrial manufacturers

Impact crusher is with unique simple structure, keyless connection. 2. slag, and glass. Stone breaker machine hammer mill crusher working principle: Stone breaker machine mainly relies on impact energy to complete the work of crushing materials. When the hammer Compare this product Hunan Sundy Science and Technology Co.,Ltd.

(PDF) NP Series Impact Crushers Hernanda Basyir

NP series of impact crushers enable to achieve a higher reduction with fewer crushing stages, lowering your capital costs and saving energy. Stationary : Primary NP1415 Impact Crusher fully hydraulic equipped. To get process benefits Very high reduction ratio. Very good cubical shape to meet asphalt and concrete product specifications for

Several Advantages of Impact Crusher CSDN博客

2012年9月20日 We all know that there are varieties types of crusher, but all of them have different strengths and weaknesses,applicable materials are also different. For example, compare the impact breaker and hammer breaker, the former has the following advantages: 1, the expected size adjustment is convenient, flexible, and the range is wide

Technical Specification Document Of Crusher Stone

2003年4月6日 Aug 16, 2011 Technical Specification Contract Document document sample parts rubber crumbs (CA 04.06.03(d)(i)) to 2 parts crusher dust Vibrating Feeder Standards,Vibrating Feeder Technical Specification

Impact crusher working technical details Manufacturer

Impact Crusher Fote Machinery sinoftm. The finished products are cubic, with good shape, no tension and cracks It can crush all kinds of coarse, medium and fine materials granite, limestone, concrete, etc,widely used in various ore crushing, railway, highway, energy, cement, chemicals, construction and other industries The size of discharge can

Impact Crusher Machines Williams Patent

The Williams Reversible Nuggetizer® Impact Crusher (U.S. Patent No. 3,667,694) is also often used for various types of automotive and metal scrap. Contact us today to discuss your application in detail with one of