crushing and grinding of magnetite

Processing of Magnetite Iron Ores–Comparing

2009年1月1日 Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls

Reducing Grinding Energy and Cost Magnetite Iron

Various magnetite ore grinding flowsheets have been implemented in the past, including: 71 • Conventional three (and four) stage crushing followed by primary and secondary

Processing of Magnetite Iron Ores Comparing

grinding is the elimination of steel grinding media costs and the need to discriminate between steel and magnetite in coarse magnetic separation ahead of pebble crushing.

(PDF) Recovery of magnetite from dry crushed feed using

2019年9月29日 The aim of this study is to examine the performance of wet drum magnetic separation on the recovery of magnetite from dry crushed feed. The steel industry has

Investigation of microcrack formation in vanadium

Characteristics of microcracks in vanadium-titanium magnetite crushed by high pressure grinding roll (HPGR) and conventional jaw crusher (JC) were investigated. In crushing by

[PDF] Investigation of microcrack formation in vanadium

2019年1月10日 Characteristics of microcracks in vanadium-titanium magnetite crushed by high pressure grinding roll (HPGR) and conventional jaw crusher (JC) were investigated.

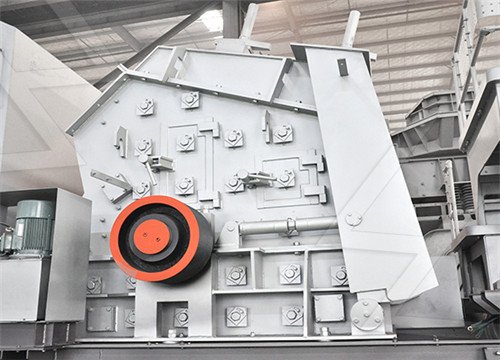

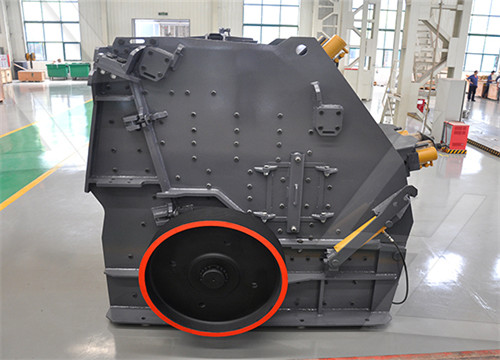

Magnetite Ore Crushing Plant,Magnetite Ore Crushing

2022年12月2日 Magnetite ore is a significant ore of iron, it is black or brownish-black with a metallic luster, has a Mohs hardness of 5–6 and a black streak. Magnetite ore

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines,

Iron ore crushing and screening process Sbmmill.net

2022年8月3日 The iron ore processing and production process mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage

Ore dressing method of narrow-level separation and

The invention belongs to the technical field of ore dressing of iron ore and relates to an ore dressing method, in particular to an ore dressing method of narrow-level separation and

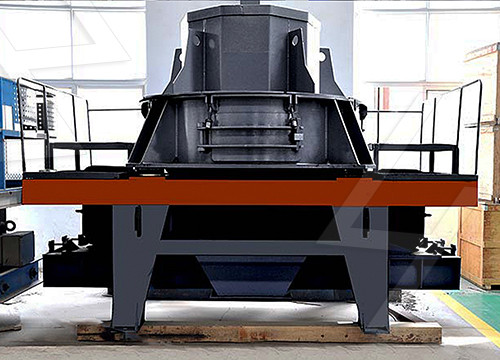

Minerals Free Full-Text Economic and Socio

2020年10月26日 In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energy-efficient technologies for dry processing of magnetite ores. The present study investigates the economic and socio-environmental benefits of applying these technologies in conceptual dry magnetite

[PDF] Investigation of microcrack formation in vanadium

2019年1月10日 Characteristics of microcracks in vanadium-titanium magnetite crushed by high pressure grinding roll (HPGR) and conventional jaw crusher (JC) were investigated. In crushing by both HPGR and JC, stress cracks, intragranular cracks, and cleavage cracks were developed. Stress cracking was the initial stage and fundamental basis of fracture.

Iron Bridge Magnetite Project, Australia Mining Technology

2020年11月2日 The Iron Bridge magnetite mine is expected to produce 22 wet million tonnes per annum (wmtpa) of high-grade, magnetite concentrate product. The processing plant will use dry crushing and grinding circuit. The plant will employ the KB 63-130 type gyratory crushers, which will be the largest crushers in the country. The crushers will be

Iron ore beneficiation technology and process

2020年12月17日 1.Single magnetite. In a medium-sized magnetic separation plant, the ore is demagnetized and then enters the crushing and screening workshop to be crushed to a qualified particle size, and then fed to the grinding workshop for grinding operations. If the ore size after grinding is greater than 0.2 mm, one stage of grinding and magnetic

Effect of magnetite content on Bond work index and

2018年4月28日 Grinding is one of the most costly operations in the mechanical breaking and mining. Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency. Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock

Magnetite Ore Crushing Plant,Magnetite Ore Crushing

2022年12月2日 Magnetite ore is a significant ore of iron, it is black or brownish-black with a metallic luster, has a Mohs hardness of 5–6 and a black streak. Magnetite ore beneficiation process is divided into crushing, grinding, classification, magnetic separation, dry tailings discharge, three phases. MAGNETITE ORE CRUSHINGPROCESSING. 1.

Magnetite Iron Ore Suppliers, Manufacturers, Wholesalers

Find Magnetite Iron Ore Suppliers. Get latest factory price for Magnetite Iron Ore. Request quotations and connect with international manufacturers and B2B suppliers of Magnetite Iron Ore. Page 1

Magnetite ore processing plant setup cost Mining

2013年3月19日 Optimising Western Australia Magnetite Circuit Design. The full scale plant is required to process 3600 grinding media cost would drop from $86M for steel primary crushed magnetite ore to a target grind P80 .

Mineral and Technological Features of

2021年3月24日 The summary data indicate the impossibility of obtaining a pure magnetite product even with the finest grinding of ore using the magnetic separation technology. As a result of magnetic separation, mainly high-grade and run-of-mine intergrowths of magnetite with hematite and quartz are extracted into the magnetite concentrate, which will lead to

Minerals Free Full-Text Study on Magnetite Ore

2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry. Microwave irradiation provides a promising solution for rock breaking. However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore. The purpose of this study is to fully understand the potential

Processing of Magnetite Iron Ores Comparing Grinding

The separation step between grinding stages progressively reduces the amount of material to be ground._x000D_ Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, has provided opportunities to further reduce the

Processing Citic Pacific Mining

2022年8月2日 The ball mills, the second stage grinding equipment, are 7.9m in diameter and 13.6m long, each with two 7800 kW motors. 52 magnetic separators are used in each of the processing lines. Two concentrate thickeners, each 45m in diameter and four tails thickeners each 90m in diameter. Four dewatering buildings, each containing seven

Effect of TiO2 on the Crushing Strength and Smelting

2016年3月21日 The effect of TiO2 on the crushing strength for high-Cr V-Ti magnetite pellets was studied in this . On one hand, the crushing strength obviously decreased with the increasing TiO2 contents. On the other hand, the crushing strength had an obvious increase after grinding treatment for the high-Cr V-Ti magnetite and titanium concentrate.

Introducing HPGR Quaternary Crushers in a Russian

2022年12月22日 The current Stoilensky magnetite concentrator comprises a three-stage crushing circuit followed by three stages of ball milling, grinding and concentration to produce a magnetite concentrate with 66.5% iron (Fe). The plant is built in four lines, three lines having four mills and one line with five mills, to treat 32 Mt/y of ore and produce 13.

Iron ore beneficiation technology and process

2020年12月17日 1.Single magnetite. In a medium-sized magnetic separation plant, the ore is demagnetized and then enters the crushing and screening workshop to be crushed to a qualified particle size, and then fed to the grinding workshop for grinding operations. If the ore size after grinding is greater than 0.2 mm, one stage of grinding and magnetic

Reducing Grinding Energy and Cost -Magnetite Iron Ore

The principles of particle breakage in crushing and grinding equipment remained mainly unchanged over the years with energy efficiency reducing as the product size decreases. Only in the last 20 years the more energy efficient technologies were successfully implemented at industrial scale including high pressure grinding rolls (HPGR) for fine