jaw crushers for slag

Fine Jaw Crushers

For high volume processing with no room for error, our fine jaw crushers are tried and tested. slag, ores, oxidic material and ferroalloys, with a feed size up to 50 mm. HSC590 Jaw Crusher a real workhorse and our larger HSC model, this jaw crusher crushes

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and

Jaw Crushers MEKA CrushingScreening Plants

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within

What Is a Jaw Crusher? Here's How It Works Cutting

2021年2月18日 A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several

Jaw Crushers Equipment For Sale or Lease Frontline

1 Frontline is proud to carry the best Jaw Crushers in Canada. Having a reliable, agile, and fuel-efficient jaw crusher is important when processing recycled concrete and

Jaw Crusher For Sale Jaw Crusher Jaw Crusher

Jaw crusher for sale. Production Capacity: 1–1200 t/h. Feeding Size: 125–1200 mm. Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore,

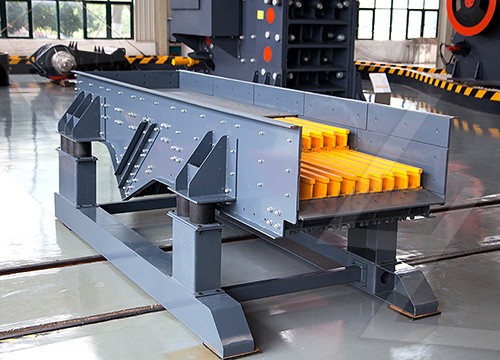

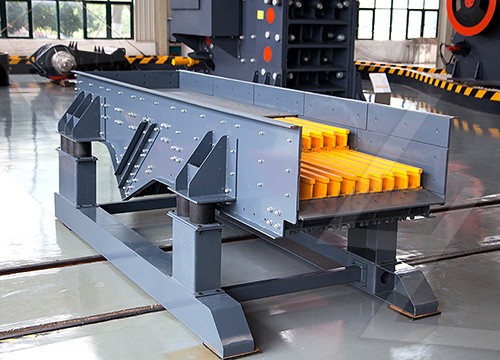

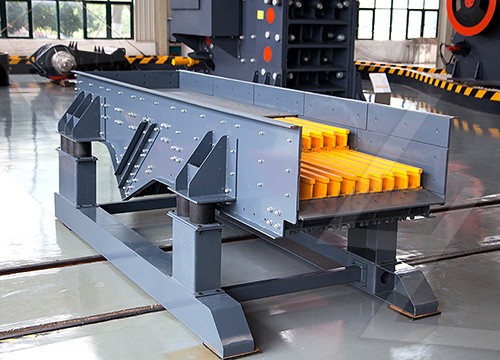

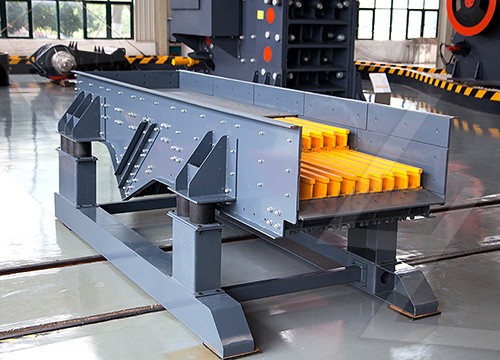

Products Slag Crusher

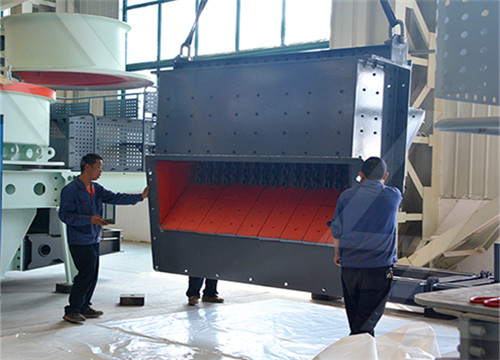

Roller Crusher is mainly used for crushing slag and it is secondary process after jaw crusher. As the material fed from Jaw crusher to roller crusher through belt conveyor, Heavy duty beater inside the roller crusher,

Slag Crusher Machine Slag Crusher

With our sound expertise, we have established very first slag crusher metal chip recovery plant that recovers more than 10% of pure metal from slag or furnace waste. Our 3000 effective running slag crusher plant throughout

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and 220. A high value reflects the capacity of a jaw crusher to accept large sample pieces and provide powerful crushing performance, resulting in high final fineness.

Jaw Crushers AGGRETEK Jaw Crushers for aggregate

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction aggregates. Recycled concrete (concrete, asphalt, etc.) Industrial Applications (slag, anodes, metallurgy, chemical industries etc.)

Jaw Crushers Retsch

2023年1月29日 Jaw width. 45 x 59 mm. Gap width setting. 0 11 mm in increments 0.1 mm. W x H x D closed. 420 x 460 x 560 mm. Net weight. ~ 79 kg. *depending on feed material and instrument configuration/settings.

Jaw Crusher for Rock Ore Slag Coal Stone Concrete

2017年2月18日 This machine is applicable to medium and fine crushed materials. Suitable for crushing materials such as calcite, talcum, cobblestone, kaolin, slag, steel slag, diabase, coom, coalgangue, maifanstone, basalt, iron ore, quartz sand, CaCO3, bentonite, ect. The feeding inlet size is 2.4-3.9inch. The feeding size should be smaller than 2.2inch.

Jaw Crusher For Sale Jaw Rock Crusher Supplies By

The rock reduced by jaw crusher is ready for impact crusher and cone crusher to do the medium and fine crushing. Jaw crusher is currently the most common crushers for sale in the world. Equipped with high-manganese-steel jaw plates, it can crush ores, rocks, steel slag, and other hard materials. It can be used in cement plants, quarries, stone

Problems and methods of improving the quality of jaw

2019年11月19日 摘要: Practically in all metallurgical treatment the raw product needs to be crushed by crushing machines. The main indicator of the crushers quality, which characterize their technical level and competitiveness, is their

Slag Crusher Plant Manufacturer India Slag Crusher

Contact Jaikar Industry Pvt. Ltd. +91 873 792 0000 for all kind of Slag Crusher Plant India, Slag Crusher Machine, Steel Slag Crusher, iron slag crusher, slag crusher plant, Slag Crusher For Steel Plant, scrap lifting magnet. Slag Crusher Plant Manufacturer India, Slag Crusher Machine, Slag Crusher For Steel Plant, Slag Crusher Manufacturer India, Ball

Jaw Crushers, Jaw Crusher for Sale, Jaw Crushers

Jaw Crushers; Hadfields 36 x 26 Jaw Crusher; Marsay Equipment specialises in the buying, refurbishment and selling of good, used Jaw Crushers. Complete the Enquiry Form below to request more information

Cooled Slag an overview ScienceDirect Topics

Composite samples of AC slag and EP slag were obtained after they were crushed by using laboratory jaw crushers. The gradations of coarse and fine AC and EP slags after crushing are summarized in Table 14.15. The gradation analyses were carried out in accordance with the ASTM C136 test method for sieve analysis of fine and coarse aggregate.

Jaw Crushers

2023年3月3日 Cast Iron Slag Warrior 800; Coal Chieftain 2100; Greywacke Maxtrak 1150 Cone Crusher; Greywacke Chieftain 2200 Screen; Hard Limestone Chieftain 2200 Screen; Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a

Jaw Crushers Heavy Duty Finlay

2023年3月2日 LJ-130 Hybrid. The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The machine features a robust 1300 x 1000mm (51

Jaw Crushers AGGRETEK portable jaw crushers.

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction aggregates. Recycled concrete (concrete, asphalt, etc.) Industrial Applications (slag, anodes, metallurgy, chemical industries etc.)

Jaw Crusher for Rock Ore Slag Coal Stone Concrete

2017年2月18日 This machine is applicable to medium and fine crushed materials. Suitable for crushing materials such as calcite, talcum, cobblestone, kaolin, slag, steel slag, diabase, coom, coalgangue, maifanstone, basalt, iron ore, quartz sand, CaCO3, bentonite, ect. The feeding inlet size is 2.4-3.9inch. The feeding size should be smaller than 2.2inch.

Mobile Crusher For Sale Mobile Crushing Plant With

Generally, mobile jaw crushers are designed for primary crushing, cone crusher is designed for medium-fine crushing, impact crusher is mainly for medium-fine crushing while some mobile impact crushers with low capacity are also used in the primary crushing. 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 . info

Problems and methods of improving the quality of jaw

2019年11月19日 摘要: Practically in all metallurgical treatment the raw product needs to be crushed by crushing machines. The main indicator of the crushers quality, which characterize their technical level and competitiveness, is their

Jaw Crusher For Sale Philippines Contact Us for Price list!

In order to meet different customers’ requirements, Aimix Group has manufactured different types of APJ series jaw crushers for the Philippines customers, It is suitable for crushing various hardness materials such as various rocks, ores, slag, concrete and construction waste. The jaw crusher capacity ranges from 1 tph to 800 tph.

Github

jaw crusher for slag crushing complete stone quarry plants. Quarry Plant,Crushing Plants,Quarry. Crushing plants Zhengzhou Machinery Co.Ltd.Zhengzhou Machinery Co.Ltd