energy saving high performance activated carbon jet mill

High-performance moisture-diffusion energy harvester

2022年12月15日 Biomass-derived activated carbon (Bio-AC) was prepared by catalytic activation of corn stover followed by milling and surface modification. The prepared Bio

The Jet Pulverizer Company Carbon Micronization : Jet

Precision Jet Milling with Proprietary “I” Mill Design; Mechanical Milling; 0.5 150 Microns APS; Carbon therefore plays a major role in improving the performance of electrodes

Jet Mill sales and supplys. Grind to less than

2023年1月24日 Jet Mills. A jet mill, or fluid energy mill, grinds material by using a high speed jet of compressed air or inert gas to impact particles into each other. Jet mills can be designed to output particles below a certain

Supersonic Steam Jet Mill ALPA Powder Equipment

2023年1月13日 High energy utilization rate, low operating cost, grinding particle size range D50: 0.5-10μm. The revolution of dry milling technology, the milled particle size can

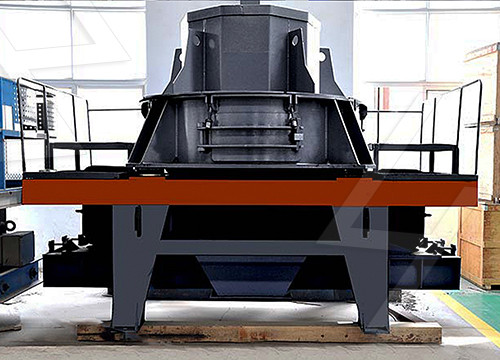

Activated Carbon Jet Mill ImagesPhotos

Product images of Activated Carbon Jet Mill, with high definitionquality a Activated Carbon Jet Mill photos Mianyang Liuneng Powder Equipment Co., Ltd. Energy

Jet Mill for Activated Carbon-ALPA POWDER

2021年12月1日 Each independent operation, complete function, compact structure, stable technical performance, high noise, high efficiency, beautiful appearance, flexible use,

HOW IT WORKS Jet Mill

2019年9月19日 Jet mill works on fluid energy. Consider a pancake spiral jet mill as an example. Micronizing and classification take place in a shallow, cylindrical chamber. High

Carbon Black Production Line Energy-saving, Low

2022年12月29日 It is in low energy consumption and high output and high efficiency. Aims at the carbon black market, Shanghai Clirik has manufactured carbon black production

Optimization of Electrochemical Performance for Activated

2022年1月31日 In this , we optimize the ratio of activated carbon (AC) and reduced graphene oxide (rGO) to fabricate their composite to improve the electrochemical performances of the rGO/AC composite-based supercapacitor. In addition, the rGO is functionalized by using an ionic liquid (F-rGO) as 1-ethyl-3-methylimidazolium

CGS Fluidized Bed Jet Mill NETZSCH GrindingDispersing

2023年3月3日 Process optimization through the adaptation of grinding conditions provides energy savings of up to 30 % compared to the conventional operation of air jet mills. Products that in the past could only be economically processed in mechanical mills, can now be micronized even more economically in our CGS Fluidized Bed Jet Mill using the e-Jet

MICRONIZER JET MILL Sturtevant Inc

2020年7月13日 Designed for high performance below 325 mesh (44 microns) — the economical fineness limit of many ENERGY REQUIREMENTS CAPACITY MILL 1 COMPRESSED AIR 2 SUPER-HEATED 3 HP LBS./HR. SIZE/DIA. STEAM 2" 30 80 10 1/2 1 4" 55 145 15 2 40 8" 130 325 40 10 100 Micronizer®: Jet mills dry particles to sub

Top 5 product-specific milling technologies

2017年7月7日 Air classifying mill for high-quality carbon black For carbon black applications that require a clean, low-grit product, the air classifying mill (ACM) is the best option. The ACM has a proven track record,

History Method of Production Structure and

2022年3月8日 Winser et al [1868] prepared activated carbon from stone mill waste and phosphate heating. An efficient method for preparing high-performance activated carbons. Hazardous Materials, 168, 2009, 882-887. [8] Delhaes, P. Design and control of structure of activated carbon materials for enhanced performance, Rand, B., Appleyard, S.P.,

Back to Basics Hammer Milling and Jet Milling

2017年10月23日 for high-speed hammer mills. In a typical jet mill, grinding action is caused mainly by particle-particle collisions, so wear to the mill’s internals is less of an issue. Toughness/brittleness. Toughness is a material’s ability to absorb energy and plastically deform without fracturing. A feed stream containing a material with a high toughness

Jet mill working principle Jet mill

1 Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media. It is also an ideal process to grind heat-sensitive and waxy material because no attritional heat is

Carbon Black Production Line Energy-saving, Low

2022年12月29日 It is in low energy consumption and high output and high efficiency. Aims at the carbon black market, Shanghai Clirik has manufactured carbon black production line . Combined with comprehensive crushing performance such as grinding, rolling and impacting, carbon black grinding mill has become the main equipment that are high

Optimization of Electrochemical Performance for Activated

2022年1月31日 In this , we optimize the ratio of activated carbon (AC) and reduced graphene oxide (rGO) to fabricate their composite to improve the electrochemical performances of the rGO/AC composite-based supercapacitor. In addition, the rGO is functionalized by using an ionic liquid (F-rGO) as 1-ethyl-3-methylimidazolium

MICRONIZER JET MILL Sturtevant Inc

2020年7月13日 Designed for high performance below 325 mesh (44 microns) — the economical fineness limit of many ENERGY REQUIREMENTS CAPACITY MILL 1 COMPRESSED AIR 2 SUPER-HEATED 3 HP LBS./HR. SIZE/DIA. STEAM 2" 30 80 10 1/2 1 4" 55 145 15 2 40 8" 130 325 40 10 100 Micronizer®: Jet mills dry particles to sub

Hammer Milling and Jet Milling Fundamentals AIChE

2023年2月28日 The jet mill is primarily used for superfine grinding applications and creates particles sizes down to a few microns. Understanding the fundamentals of each mill’s respective grinding mechanisms, operating philosophies, and best maintenance practices is essential to achieving good product quality, energy savings, and high throughput.

History Method of Production Structure and

2022年3月8日 Winser et al [1868] prepared activated carbon from stone mill waste and phosphate heating. An efficient method for preparing high-performance activated carbons. Hazardous Materials, 168, 2009, 882-887. [8] Delhaes, P. Design and control of structure of activated carbon materials for enhanced performance, Rand, B., Appleyard, S.P.,

Activated Carbon and its Applications Donau Carbon

2018年1月15日 activated carbon and with the construction of plants in which it is used. Activated carbon lies at the heart of a number of different processes used in the industry. Environmental problems affecting air and water are solved through the use of activated carbon, and new applications are being continually developed in rapid succession.

s-Jet Steam Jet Mill NETZSCH GrindingDispersing

17 小时之 Compared to air, steam provides considerably higher jet energy. Jet speeds of up to 1,200 m/s can be achieved (Air about 550 m/s) and the kinetic impact energy of the particles inside the fluid bed rises fourfold! This allows achieving finer particles in dry –grinding process as opposed to air operations.

Jet mills : what is it ? How jet milling works

2021年10月26日 2. How does a jet mill work ? The working principle of jet mills is explained in this part. 2.1 High velocity impact The principle of size reduction applied in a jet milling machine is to have high velocity impact, in between the particles, and in between the particles and the milling chamber.A gas (typically air, for air jet mills) injected at high

Supersonic Steam Jet Mill ALPA Powder Equipment

2023年1月13日 High energy utilization rate, low operating cost, grinding particle size range D50: 0.5-10μm. The revolution of dry milling technology, the milled particle size can reach sub-micron or nanometer level, which greatly improves the energy utilization efficiency and realizes low carbon, energy saving, environmental protection and resource recycling by

Frequently Asked Questions : Jet Pulverizer

Materials that degrade with heat or have low melt temperatures are a problem in hammer mills because of the heat generated in the mill.In 1936 the first commercially practical jet mill or spiral jet mill was introduced. This was the predecessor to our current Micron-Master® design. Up to that time, dry grinding in the sub-sieve range of 625 to