rod mill the best quality mining rod mill working principle

Rod Mill an overview ScienceDirect Topics

Rod mills are used in an open circuit between crushing and the ball mill. They often operate in wet and where the pulp contains up to 50% solid by mass. This machine is equally very applicable to dry where it could take a feed that has achieved 6% moisture. As such,

Rod Mills Mineral ProcessingMetallurgy

2016年5月31日A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of

Rod Mills Grinding Mills DOVE

2021年3月16日ROD MILL WORKING PRINCIPLE: DOVE Rod Mill also referred to as steel rod mill shape is similar to DOVE Ball Mill, and is characterized by the use of steel

The Working Principle and Structure of Rod Mill Mining-pedia

Working Principle of Rod MillMain Structure of Rod MillConclusionRod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operation. Is through asynchronous motor reducer with small gear coupling, the surrounding big gear reduction drive under its impetus, drive the rotary rotate, cylinder body is equipped with the grindi在miningpedia.net上查看更多信息

Highly Efficient Rod Mill Fote Machinery

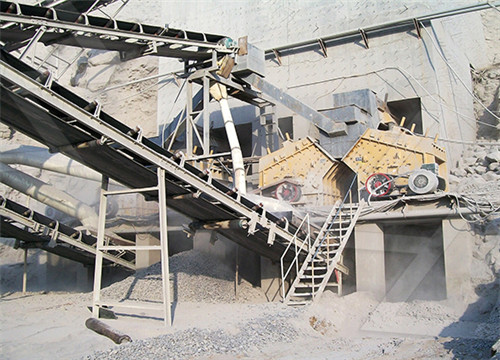

Rod mill on working site. 1 The rod mill usually uses a steel rod with a diameter of 50-100 mm as a grinding medium. The length of the steel rod is 25-50 mm shorter than that of the cylinder, and is usually made of high

Rod Mill YouTube

2017年7月10日The Working Principle of Ball Mill Fote Machinery (FTM Company) 67K views 2 years ago You're signed out of YouTube Sign in to like videos, comment, and

Comparative Analysis of Rod Mill and Ball Mill Ball Mills Supplier

2020年5月8日The reason why rod mill is called rod mill is that its grinding medium is steel rod, while the grinding medium of ball grinding mill is steel ball. Because the shape of the grinding media is different, the

Rod Mill, Rod Mill Manufacturers, Rod Mill Working Principle, Rod

(1) Rod mill is usually selected in order to prevent over-grinding in gravity or magnetic separation plant of tungsten tin and other rare metals mine; (2) In two stages grinding,

Rod Mill an overview ScienceDirect Topics

Rod mills are used in an open circuit between crushing and the ball mill. They often operate in wet and where the pulp contains up to 50% solid by mass. This machine is equally very applicable to dry where it could take a feed that has achieved 6% moisture. As such, when the product is sticky, rod mills are preferred over ball mills.

The Working Principle and Structure of Rod Mill

2019年10月17日In this post, we're going to learn more about rod mill. We'll cover it from two aspects: 1. Working principle. 2. Structure. Let's dive right in! 1. Working Principle of Rod Mill. Rod mill is a common

The Working Principle and Structure of Rod Mill LinkedIn

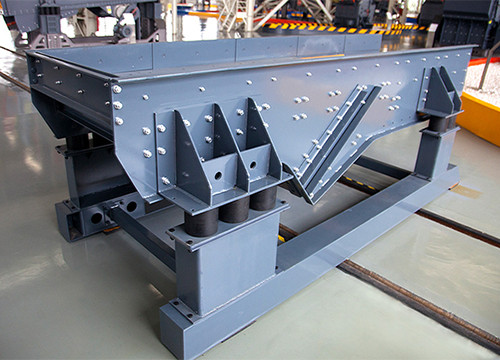

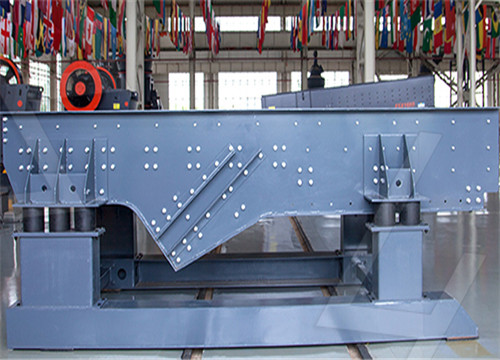

2019年11月6日This kind of main structure mainly has 15 parts: 1. 2. Main bearing department. 3. Hydraulic jacking device. 4. High and low pressure pump station. 5. Rotating part.

7 Differences Between Ball Mill and Rod Mill Xinhai

2018年11月29日Although they have the similar working principle, there are many differences between ball mill and rod mill on details. 1. Configuration of ball mill and rod mill. The proportion of cylinder shape

Rod Mill with Good Price for Mining Industrial Ore

Rod Mill. Feeding size: ≤50mm. Capacity: 0.62-180t/h. Output size: 0.833-0.147mm. Applications: Rod mills are widely used in refractory, chemical, metallurgy, glass and other industries. Especially suitable for grinding

Working principle and application of rod mill Grinding Ball

2021年2月18日Working principle of rod mill. Rod mills run along the outside gear. Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices. Steel rods of different specifications are installed in the crushing chamber. When the frame rotates, centrifugal force is produced.

Rod Mills Archives Mineral ProcessingMetallurgy

Rod Mills Cement Grinding The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and

Rod mill video YouTube

2018年12月17日The rod mill is a grinding machine with steel rod as grinding medium, mainly used for rough grinding operation. It is generally used as wet overflow type and can be used as one-stage open...

rod mill manufacturers ,grinding rod supplier- walker

So our rod mills are greatest efficiency, easy to operate, effective and energy saving. They are popular in the mining industry. Structure The rod mill is composed by the feeding part, feeder part, discharging part, cylinder part, main bearing part and driving part. Working Principle When rod mill works, the elector motor accords reduction

Grinding Mills — Types, Working PrincipleApplications

2018年8月17日Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to approximately 50 mm. (2 in.) and

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world electric power. The objective of this...

The Working Principle and Structure of Rod Mill LinkedIn

2019年11月6日This kind of main structure mainly has 15 parts: 1. 2. Main bearing department. 3. Hydraulic jacking device. 4. High and low pressure pump station. 5. Rotating part.

7 Differences Between Ball Mill and Rod Mill Xinhai

2018年11月29日The rod mill is often applied in gravity separation and magnetic separation of tungsten, tin ore and other rare metal ores. In the second stage grinding process, the rod mill is generally used as the first

Rod Mill with Good Price for Mining Industrial Ore

The rod mill working principle and structure is roughly the same as that of the overflow ball mill, but there are also differences. Different grinding media. Unlike the ball mill machine, the mining rod mill also called

Introduction of Rod Mill Working Principles or Operation Xinhai

2016年4月20日In beneficiation production, rod mills are one of the main grinding equipment. Here is some introduction of rod mill working principles or operation. Rod mills are suitable for coarse grinding operation. Rod mill operation are as follow. With asynchronous motor speed reducer and small wheel gear connected, the peripheral big

Grinding Machines: Types and Selection Principles

2020年9月22日The processing capacity of ball mills and rod mills is usually calculated by volumetric method or power consumption method, and the selection of ore mill should meet the following requirements: 1) Rod

Rod Mills Energy Saving Rod Mill For Sale AGICO

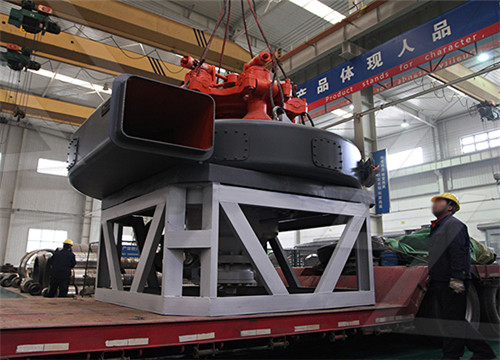

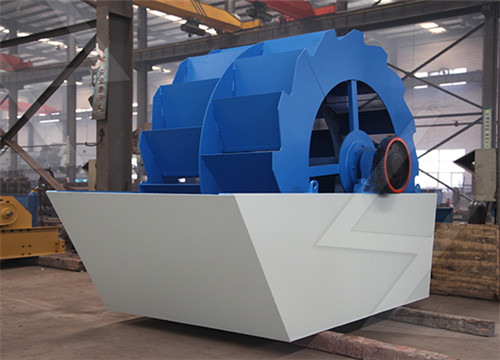

ROD MILL WORKING PRINCIPLE The rod mill is mainly composed of the feeding part, cylinder, transmission device, coupling, discharging part, steel rod, lining plate, and so on. Rod Mill Structure The motor drives the

Ball vs Rod vs Roll Mills Gold RefiningMetal Extraction Forum

2019年6月11日A roll mill is two opposing rotating hard-faced rollers, one mounted stationary and the other under heavy spring tension. The material to be ground is fed between the rollers and is nipped crushed by pressure tension, versus the crushing abrasion of the ball/rod mills. The roll mill can also be operted wet or dry.

rod mill manufacturers ,grinding rod supplier- walker

So our rod mills are greatest efficiency, easy to operate, effective and energy saving. They are popular in the mining industry. Structure The rod mill is composed by the feeding part, feeder part, discharging part, cylinder part, main bearing part and driving part. Working Principle When rod mill works, the elector motor accords reduction

Working principle and application of rod mill Grinding Ball

2021年2月18日Working principle of rod mill Rod mills run along the outside gear. Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices. Steel rods of different specifications are installed in the crushing chamber. When the frame rotates, centrifugal force is produced.

Rod Mill Manufacturer/Supplier, Rod Mill Price, Rod Mill For Sale

StructureWorking Principle of Rod Mill The rod mill is driven by the motor through the reducer and the surrounding large gear or by the low-speed synchronous motor directly through the surrounding gear to drive the shell rotation. The shell is equipped with the appropriate grinding medium steel rod.

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world electric power. The objective of this...

Rod mill SlideShare

2017年4月10日Rod mill b. Ball mill c. Tube mill. # Rod mill • Description The rod mill is a tumbling mill but having a large percentage of its volume (30 40%) loaded with steel rods. The rods are placed axially in the mill and are loose and free to move within the mill. The internal lining of the drum has a series of lifters which raise the rods and

Rod Mill:Introduction and Category of Rod Mill

2017年2月15日Working Principle of Rod Mill: Rod mill makes tube run with the help of the reduction gears drove by dynamo or the low speed synchronization electrical machine. There are steel balls in the tube