mill vibration mill

How to reduce vibration in milling Coromant

The cutting tool. With 90° cutters, the dominant forces focus in the radial direction. This

Study on Vibration Asymmetry of Hot Rolling Mill with Structural

2023年2月13日The study of mill vibration is usually the study of horizontal vibration (Mazur et al. 2016 ), vertical vibration (Niziol and Swiatoniowski 2005) and torsional

How to reduce vibration in milling Coromant

The cutting tool. With 90° cutters, the dominant forces focus in the radial direction. This

Vibration Energy Coupling Behavior of Rolling Mills under Double

2023年2月20日The essence of mill vibration is the energy transfer process. The flow of vibrational energy transferred to a region of the structure can be described by the

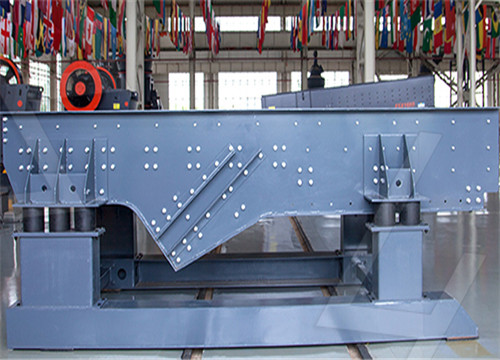

What Is a Vibration Mill, What is Vibration Mill Used For?

A vibration mill is an important tool for achieving precise and efficient particle size reduction, grinding, and polishing of materials. Its unique approach to milling offers

Mill Vibration Phenomena during Cold Rolling Innoval Technology

2016年11月8日The simplest type of mill vibration is found in all mills. It is a forced vibration due to roll eccentricity and so occurs at roll rotation frequencies. These frequencies are usually lower than any of the

GrindingCrushing Mill VIBRA-DRUM® General Kinematics

VIBRA-DRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven

Vibration Mill Qingdao EPIC Powder Machinery

A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function. The grinding container is made up of

Tech Tip: Reducing ChatterVibration in End Milling Kennametal

Use end mills with reduced clearance or a small circular margin. Use the shortest overhang from spindle nose to tip of tool. Use stub length end mills where possible. Use balanced

Vibratory Ball Mill Industrial Vibration Ball Mill For Sale AGICO

Vibratory ball mills use high-frequency vibration to make grinding media in the cylinder produce inertial impact force. Raw materials are ground under the impact. The grinding

Study on Vibration Asymmetry of Hot Rolling Mill with Structural

2023年2月13日The study of mill vibration is usually the study of horizontal vibration (Mazur et al. 2016 ), vertical vibration (Niziol and Swiatoniowski 2005) and torsional vibration (Abro and Atangana 2021) of the mill, as well as by the mutual coupling vibration of these vibrations (Hollebeke et al. 2006; Ji 2017 ).

How to reduce vibration in milling Coromant

Milling vibration can arise due to limitations in the cutting tool, the holding tool, the machine, the workpiece or the fixture. To reduce vibration, there are some strategies to consider. The cutting tool With 90° cutters, the dominant forces focus in the radial direction.

Vibration Energy Coupling Behavior of Rolling Mills under Double

2023年2月20日The essence of mill vibration is the energy transfer process. The flow of vibrational energy transferred to a region of the structure can be described by the structural sound intensity method, which combines force and velocity at any point in an elastic structure to characterize the flow of energy in a vibrating structure.

Prediction and analysis of cold rolling mill vibration based on a

2020年11月1日The vibration prediction analysis method for hot strip mill based on eXtreme gradient boosting (XGBoost) and Bayesian optimization (BO) and a comprehensive comparison is made between the prediction model in this stone and other well-known machine learning benchmark models. Expand PDF View 1 excerpt, cites methods 1 2

GrindingCrushing Mill VIBRA-DRUM® General

VIBRA-DRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven

Vibration Mill Qingdao EPIC Powder Machinery

A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function. The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel balls.

Principle of Vibration Milling and Its Industrial Applications

Vibration milling is a type of mechanical milling that utilizes vibrations to generate an impact force that breaks down particles into smaller sizes. This process is commonly used in various industries for material processing and synthesis.. Vibration milling is a milling process that uses the principles of mechanical vibration and impact to reduce the

A review of chatter vibration research in milling 百度学术

A review of chatter vibration research in milling. 来自 万方. 喜欢 0. 阅读量:. 8. 摘要:. Chatter is a self-excited vibration of parts in machining systems. It is widely present across a range of cutting processes, and has an impact upon both efficiency and quality in p 查看

Tunable vibration absorber for improving milling stability with

2016年1月1日Among passivetechniques, tunable vibration absorbers tunedviscoelastic dampers turning[19], boring [20–22] millingprocesses [23,24] have been used chattersuppression. Also, change spindlespeed chatteravoidance chatterprevention acousticsignal feedback have been investigated [25,26].

Torsional Vibration Analysis on Drive System of Carrousel Coiler

Based on study of the Carrousel coiler' s driye system, its mechanical model is established by using the lumped mass parameter model. And in combination of Lag

12 Ways to Reduce Cutting Vibrations on CNC Milling Machines

2023年2月18日In milling thin-walled workpieces, the cause of vibrations is solely from the workpiece, also known as a box or bowl part. Since the vibration originates from the workpiece itself, the primary focus when handling the milling of such parts is to enhance the clamping of the workpiece. 08

Prediction and analysis of cold rolling mill vibration based on

2020年11月1日In this , a data-driven mill vibration analysis method is proposed. The main objective of this study was to develop a mill vibration monitoring method and an intelligent algorithm for mill chatter early warning. Rolling experiments showed that the proposed monitoring method could be a promising and effective technique for assessing

Tech Tip: Reducing ChatterVibration in End Milling Kennametal

Use a larger end mill with a larger core diameter. Use end mills with reduced clearance or a small circular margin. Use the shortest overhang from spindle nose to tip of tool. Use stub length end mills where possible. Use balanced tool holders. Rework fixture to hold the workpiece more securely.

Influence of mill modulus control gain on vibration in hot

2020年4月22日The mill vibration has become a bottleneck in the thin steel strip manufacturing [1, 2], as the mill vibration can cause unacceptable thickness variations in the steel strip, and even severely damage the mill equipment [3, 4].The coupling effect among subsystems has been widely investigated to obtain the vibration suppression

Vibration Energy Coupling Behavior of Rolling Mills under Double

2023年2月20日The essence of mill vibration is the energy transfer process. The flow of vibrational energy transferred to a region of the structure can be described by the structural sound intensity method, which combines force and velocity at any point in an elastic structure to characterize the flow of energy in a vibrating structure.

Prediction and analysis of cold rolling mill vibration based on a

2020年11月1日The vibration prediction analysis method for hot strip mill based on eXtreme gradient boosting (XGBoost) and Bayesian optimization (BO) and a comprehensive comparison is made between the prediction model in this stone and other well-known machine learning benchmark models. Expand PDF View 1 excerpt, cites methods 1 2

Vibration Mill Qingdao EPIC Powder Machinery

A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function. The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel balls.

Principle of Vibration Milling and Its Industrial Applications

Vibration milling is a type of mechanical milling that utilizes vibrations to generate an impact force that breaks down particles into smaller sizes. This process is commonly used in various industries for material processing and synthesis.. Vibration milling is a milling process that uses the principles of mechanical vibration and impact to reduce the

A numerical analysis of the movement of balls in a vibration mill

1994年10月1日The U.S. Department of Energy's Office of Scientific and Technical Information

A review of chatter vibration research in milling 百度学术

A review of chatter vibration research in milling. 来自 万方. 喜欢 0. 阅读量:. 8. 摘要:. Chatter is a self-excited vibration of parts in machining systems. It is widely present across a range of cutting processes, and has an impact upon both efficiency and quality in p 查看

Tunable vibration absorber for improving milling stability with

2016年1月1日Among passivetechniques, tunable vibration absorbers tunedviscoelastic dampers turning[19], boring [20–22] millingprocesses [23,24] have been used chattersuppression. Also, change spindlespeed chatteravoidance chatterprevention acousticsignal feedback have been investigated [25,26].

Torsional Vibration Analysis on Drive System of Carrousel Coiler

Based on study of the Carrousel coiler' s driye system, its mechanical model is established by using the lumped mass parameter model. And in combination of Lag

Prediction and analysis of cold rolling mill vibration based on

2020年11月1日In this , a data-driven mill vibration analysis method is proposed. The main objective of this study was to develop a mill vibration monitoring method and an intelligent algorithm for mill chatter early warning. Rolling experiments showed that the proposed monitoring method could be a promising and effective technique for assessing

vibration seat massage cushion pad pellet making machine- pellet mill

Quality vibration seat massage cushion pad pellet making machine- pellet mill find quality Pellet mill, Wood Pellet MillPellet mill from Zhangqiu Long Teng Cement Machinery Making Co., Ltd. of China Suppliers .

Vibration Characteristics of Rolling Mill System under Hindawi

2021年1月19日The vibration of rolling mill system is influenced by the nonlinear spring force and nonlinear friction force of the hydraulic cylinder of rolling mill. By taking different nonlinear spring force and friction coefficient, the variation law of time-domain response is simulated and analyzed. The simulation results are shown in Figures 3 5. (c) (a)