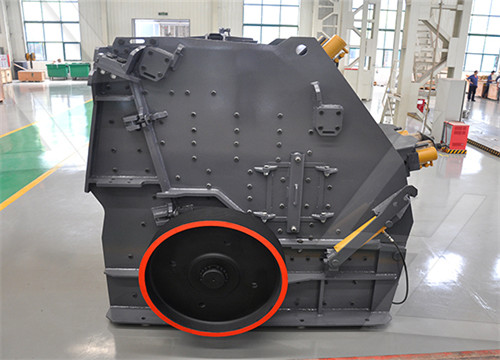

hc series small impact crusher mining stone impact crusher

Impact Crushers Primary McLanahan

VersaCap Impactors are engineered wih a simple hydraulic-assisted shim adjustment to minimize downtime while keeping the crusher operating at optimum performance. They

Horizontal Impact Crusher HHI

The HHI Horizontal Impact Crusher comprises two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the

Learn more information of HC Series Impact Crushers

HC Series Impact Crushers can crush kinds of soft and medium-hard ore, for coarse, medium and fine crushing, in primary and secondary crushing process. The series can

Impact Crusher Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the

HC Series Stone Impact Crusher Machine HC crusher SANME

HC Series Stone Impact Crusher Machine HC crusher SANME crusher machine Products Made In China, China Manufacturer. HC Series Impact Crushers are built on

RM60 Small Impact Crusher Concrete. Asphalt. Rock. RUBBLE

Small Impact Crusher. Capacity 90 TPH. Inlet opening 25” x 22”. Weight 29,800 lbs. Imperial / metric. Please note: new RM 60 models are currently not available in the

Impact Crusher Rock Crusher Machine Manufacturer JXSC Mine

Impact Crusher Application Field JXSC impact stone crushers are widely used in quarrying, concrete recycling and mining which as a primary, secondary, tertiary crusher. It can crush the materials that pebble,

Small Impact Stone Crusher

PF Impact Crusher Fine Mining Machine for sale. With the typical PF series, the impact crushers are widely used for the secondary and tertiary crushing process. They can

Home made Impact mill rock crusher for gold ore. YouTube

2015年4月27日This video examines the makeup and use of my home made impact mill rock crusher for liberating gold from gold ore. I explain hoe to make a rock crusher or a...

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield

Crushing Metso Outotec

Metso Outotec in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso Outotec is able to deliver successful IPCC operations.

Learn more information of HC Series Impact Crushers

HC Series Impact Crusher Products Information. Products features and technology advantages: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance.

Horizontal Impact Crusher HHI

The HHI Horizontal Impact Crusher comprises two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the horizontal chain conveyor permits the conveyor to be utilised as both feed conveyor and discharge conveyor.

Impact Crusher Sanme

HC Series Impact Crushers can crush kinds of soft and medium-hard ore, for coarse, medium and fine crushing, in primary and secondary crushing process. The series can be widely used in mining, construction, chemical, cement, metallurgical industries, etc. Common Malfunction: A:If abnormal vibration of impact crusher is found:

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

continues unti l the pieces are small enough to fall through the nar row opening at the bottom of the crusher. IMPACT CRUSHER Impact crushers, which are also called hammer mills, break rock by impacting the rock with hammer s that s wing on a rotati ng shaf t. The pr acti cal use of impact cr usher s is limited to sof t

Impact Crusher Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the impact energy. An impact crusher speeds up the feed material to high speed, then throws fast-moving rocks against the crushing chamber walls and each other.

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023年2月15日Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make

Impact Crusher Rock Crusher Machine Manufacturer JXSC Mine

JXSC impact stone crushers are widely used in quarrying, concrete recycling and mining which as a primary, secondary, tertiary crusher. It can crush the materials that pebble, granite, basalt, iron ore, limestone, quartz, diabase, etc. Capacity (t/h): 30-500 Max Feed Size (mm): 300-700 All models of jxsc impact crushers +

RM60 Small Impact Crusher Concrete. Asphalt. Rock. RUBBLE

Small Impact Crusher Capacity 90 TPH Inlet opening 25” x 22” Weight 29,800 lbs Imperial / metric Please note: new RM 60 models are currently not available in the United States and Canada. Meet us at ConExpo 2023 Silver Lot March 14-18 learn more Turn Your Material into Profits

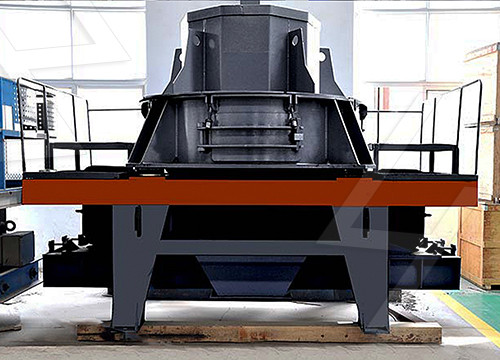

Vertical Shaft Impact Crusher AF Minerals Equipment

The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency. In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operations.

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores. The principles used for impact loading is the time for the natural frequency of the...

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield

Crushing Metso Outotec

Metso Outotec in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso Outotec is able to deliver successful IPCC operations.

Learn more information of HC Series Impact Crushers

HC Series Impact Crusher Products Information. Products features and technology advantages: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance.

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

continues unti l the pieces are small enough to fall through the nar row opening at the bottom of the crusher. IMPACT CRUSHER Impact crushers, which are also called hammer mills, break rock by impacting the rock with hammer s that s wing on a rotati ng shaf t. The pr acti cal use of impact cr usher s is limited to sof t

Hc Series Impact Crusher at Best Price in Shanghai Shanghai

Shanghai Sanme Mining Machinery Co., Ltd is a subsidiary of Germany JV company in China. &EPR GmbH was founded in 1946 by the inventor of impact crusher Dr. Andreas. By many years experience, Sanme has developed the HC Series Impact Crushers with world advanced level. The crushing chamber is optimized, the

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

RM60 Small Impact Crusher Concrete. Asphalt. Rock. RUBBLE

Small Impact Crusher Capacity 90 TPH Inlet opening 25” x 22” Weight 29,800 lbs Imperial / metric Please note: new RM 60 models are currently not available in the United States and Canada. Meet us at ConExpo 2023 Silver Lot March 14-18 learn more Turn Your Material into Profits

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023年2月15日Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make

Vertical Shaft Impact Crusher AF Minerals Equipment

The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency. In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operations.

Impact Crusher Rock Crusher Machine Manufacturer JXSC Mine

JXSC impact stone crushers are widely used in quarrying, concrete recycling and mining which as a primary, secondary, tertiary crusher. It can crush the materials that pebble, granite, basalt, iron ore, limestone, quartz, diabase, etc. Capacity (t/h): 30-500 Max Feed Size (mm): 300-700 All models of jxsc impact crushers +

Crusher an overview ScienceDirect Topics

The impact crusher ( Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs.

Design of impact stone crusher machine ResearchGate

Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

All crusher types for your reduction needs Metso Outotec

Primary crushing with impact crushers. The primary impact crusher offers high capacity and is designed to accept large feed sizes. The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and