type of pebbles used in ball mill in ceramic industry

Flint Pebble > ATEMS

Silica pebbles can be used as a grinding medium for ceramics ball mill. It is suitable for all kinds of ceramic raw materials. Our high silica content flint pebbles are usually used in

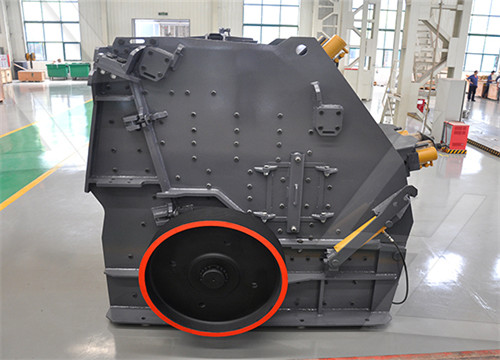

Pebble Mill Application and Design Paul O. Abbe

Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, minerals for ceramics and

On the Use of Ball Milling for the Production of Ceramic Powders

2015年4月22日In the present research work the mixture of boron carbide and graphite ceramic powders with a theoretical composition of 50%

The Top 2 Types of Ceramic Alumina Balls used for Grinding in

2021年5月8日There are also other types, such as natural balls, stones, and pebbles used for grinding ball mills. Ball mills used in ceramic tiles factories are of 40 ton and 60-ton capacity. Nowadays, the usage of 60

Steatite Ceramic Grinding Balls and Media Steatite ceramic

Steatite ceramic balls and mill lining bricks are manufactured from the same fine-grained composite and are ideal performance partner. Thus, they retain their shape better and

Grinding Mills Common Types Mineral ProcessingMetallurgy

2016年11月7日The pebble mill is the name associated with a mill in which the grinding bodies are natural pebbles or possibly ceramic bodies; the general proportions of the mill being as for a “ball mill”. It will be

Ball Mills, Pebble Mills, Material Processing Mills Hatboro PA,

Ball Mills. Patterson is the industry leading supplier of wet and dry grinding mills for size reduction or dispersal. ceramic, rubber or stone linings; Direct or gear drives or as a

type of pebbles used in ball mill in ceramic industry

type of pebbles used in ball mill in ceramic industry China Custom Flint Pebble for Ceramic Industry Mainly used to grind all kinds of mineral materials for ceramic

Flint Pebble > ATEMS

Silica pebbles can be used as a grinding medium for ceramics ball mill. It is suitable for all kinds of ceramic raw materials. Our high silica content flint pebbles are usually used in ceramic or insulator industries as Grinding Media. To mill or grind raw materials like sand, kaolin clay, feldspar and other materials in ball mill.

Milling and Mixing Materials Research Institute

Ball mill is typically used to grind and/or blend materials and it can be done wet or dry. It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc. Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Pebble Mill Application and Design Paul O. Abbe

Pebble Mill Application and Design Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass, advanced ceramics,

Ball Milling Glazes, Bodies, Engobes Digitalfire

A true ball mill is a porcelain jar partly filled with spherical or rounded cylindrical porcelain balls. Industrial versions are made of metal and have porcelain linings. Small scale operations most commonly employ ball mills for grinding glazes. The suspension is poured in, a lid secured, and it is rotated on a motorized rack, sometimes for

Addition of pebbles to a ball-mill to improve grinding efficiency

2017年4月1日The idea of using a mixture of balls and pebbles, at a mill speed suitable for ball-milling, was revisited in this investigation, using a normal spectrum of pebble sizes (19–75 mm). Batch tests in a pilot-scale mill (0.57 m diameter) were used to compare ball-milling to various ball/pebble mixtures. The mill power was measured online by

Grinding Mills Common Types Mineral Processing

2016年11月7日The pebble mill is the name associated with a mill in which the grinding bodies are natural pebbles or possibly ceramic bodies; the general proportions of the mill being as for a “ball mill”.

Addition of pebbles to a ball-mill to improve grinding efficiency

2016年9月1日This stone compares the performance of a 25/75 pebble/ball (volume ratio) composite charge to ball-milling, under conditions typical for a ball-mill in SABC circuits, i.e. a large...

Grinding In Ball Mill: Techniques And Processes Molycop

2020年12月17日You probably know that grinding in ball mills is a crucial technological process applied to reduce the size of particles. The particle may have different nature and diversity of physical and chemical characteristics. A machine is used to reduce the particle size of materials. The ball mill is a container filled with pebbles either of porcelain and

Used Ceramic Ball Mill for sale. Paul O. Abbe equipmentmore

Search for used ceramic ball mill. Find Paul O. Abbe, Allis-Chalmers, and Metso for sale on Machinio. used 21 in. x 17 in. Patterson Pebble Mill with ceramic chamber. With 6 in. round inlet with stainless steel door. 1 HP motor, chain and sprocket to gear reducer, 3/60/208-230/460V. x 4' (1.22 m), ceramic lined, batch type mill. Total

Ball milling Digitalfire

A device used to reduce the particle size of materials, bodies or glazes. A ball mill is simply a container that is filled with pebbles (either of porcelain or stones e.g. Flint) into which a charge (powder or slurry) is put and that is then mechanically rotated to cause the tumbling pebbles to crush particles that happen between them.

Ball, Pebble and SAG Mills: A Buyers Guide Surplus Record

The Ball Mill, the Pebble Mill and the SAG Mill are 3 of the most popular types of mills on the industrial market. They are primarily used for the Mining industry, but they can also be used in the ChemicalProcessing industry which has it’s own category page for those listings here: Ball, Pebble, SAG Mills for Chemical Use .

Addition of pebbles to a ball-mill to improve grinding efficiency

Nkwanyana and Loveday (2017) used batch grinding experiments in a 0.6 m diameter mill to test partial replacement of steel balls (37.5 mm) for secondary grinding, by partly rounded pebbles (19–75 mm) from a SAG mill. At the optimum pebble content of 25% by volume, a 25% saving in steel ball consumption and a 15% saving in energy consumption

Flint Pebble > ATEMS

Silica pebbles can be used as a grinding medium for ceramics ball mill. It is suitable for all kinds of ceramic raw materials. Our high silica content flint pebbles are usually used in ceramic or insulator industries as Grinding Media. To mill or grind raw materials like sand, kaolin clay, feldspar and other materials in ball mill.

Ball Milling Glazes, Bodies, Engobes Digitalfire

A true ball mill is a porcelain jar partly filled with spherical or rounded cylindrical porcelain balls. Industrial versions are made of metal and have porcelain linings. Small scale operations most commonly employ ball mills for grinding glazes. The suspension is poured in, a lid secured, and it is rotated on a motorized rack, sometimes for

Milling and Mixing Materials Research Institute

Ball mill is typically used to grind and/or blend materials and it can be done wet or dry. It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc. Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Addition of pebbles to a ball-mill to improve grinding efficiency

2017年4月1日The idea of using a mixture of balls and pebbles, at a mill speed suitable for ball-milling, was revisited in this investigation, using a normal spectrum of pebble sizes (19–75 mm). Batch tests in a pilot-scale mill (0.57 m diameter) were used to compare ball-milling to various ball/pebble mixtures. The mill power was measured online by

Pebble Mill Application and Design Paul O. Abbe

Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, minerals for ceramics and semiconductor materials down to 1 micron or less. The residence time in pebble mills is assures that all particles are given consistent

On the Use of Ball Milling for the Production of

2015年4月22日Ceramic ball bearings are extensively applied in the precision machinery transmission field due to their high temperature resistance [96,97], low density [98, 99], high hardness and toughness...

Ball milling Digitalfire

A device used to reduce the particle size of materials, bodies or glazes. A ball mill is simply a container that is filled with pebbles (either of porcelain or stones e.g. Flint) into which a charge (powder or slurry) is put and that is then mechanically rotated to cause the tumbling pebbles to crush particles that happen between them.

Addition of pebbles to a ball-mill to improve grinding efficiency

Nkwanyana and Loveday (2017) used batch grinding experiments in a 0.6 m diameter mill to test partial replacement of steel balls (37.5 mm) for secondary grinding, by partly rounded pebbles (19–75 mm) from a SAG mill. At the optimum pebble content of 25% by volume, a 25% saving in steel ball consumption and a 15% saving in energy consumption

Grinding In Ball Mill: Techniques And Processes Molycop

2020年12月17日You probably know that grinding in ball mills is a crucial technological process applied to reduce the size of particles. The particle may have different nature and diversity of physical and chemical characteristics. A machine is used to reduce the particle size of materials. The ball mill is a container filled with pebbles either of porcelain and

Used Ceramic Ball Mill for sale. Paul O. Abbe equipmentmore

21″ x 17″ PATTERSON PEBBLE MILL CERAMIC CHAMBER USED Manufacturer: Patterson 1 used 21 in. x 17 in. Patterson Pebble Mill with ceramic chamber. With 6 in. round inlet with stainless steel door. 1 HP motor, chain and sprocket to gear reducer, 3/60/208-230/460V. On stand with motor starte USA Click to Request Price

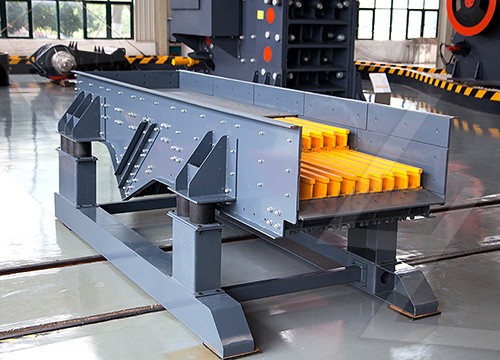

CERAMIC MATERIALS I Mu

Fine grinding or milling reduces the particle size down to as low as 1.0 micrometer (μm) (4 x 10-5 in.) in diameter. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition mills, and fluid energy mills also are used.

Ball, Pebble and SAG Mills: A Buyers Guide Surplus Record

The Ball Mill, the Pebble Mill and the SAG Mill are 3 of the most popular types of mills on the industrial market. They are primarily used for the Mining industry, but they can also be used in the ChemicalProcessing industry which has it’s own category page for those listings here: Ball, Pebble, SAG Mills for Chemical Use .

Ball mill Cerámica Wiki Fandom

Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls. An internal cascading

What is the Difference Between SAG and AG Mill?

There are different types of mills, including SAG and AG mills. These two types of mills are used in the mining industry to grind and crush ore. What is a SAG Mill? A SAG mill is a type of mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1.5 to 2.5 times the diameter of the shell.