mechanical design of pulverizer

DESIGN AND FABRICATION OF PULVERIZER MACHINE: A REVIEW

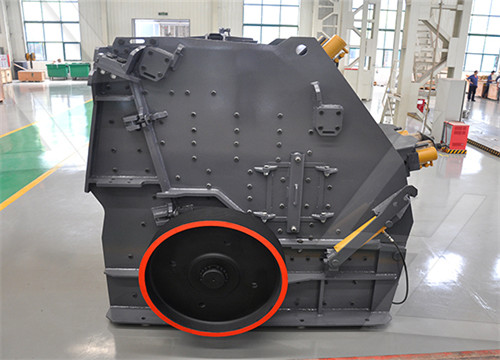

DESIGN AND FABRICATION OF PULVERIZER MACHINE: A REVIEW. International Journal of Advance Research and Innovative Ideas in Education. Pulveriser is a hay or

Design and Development of Pulverizer for Non-Ferric Alum

2018年4月24日A Pulverizer is a mechanical device for the grinding of different types of materials. Under pulverizer concept we have to select one of types of crusher. Crushers

Pulverizers 101: Part I POWER Magazine

2011年8月1日Here is our four-step plan to restore and improve performance of your pulverizer, regardless of its age. Step 1. Ensure that the grinding elements are in good condition. Make sure that the...

Pulverization 2: Pulverization method and pulverizer

2019年10月31日The rotation and revolution nano-pulverizer is a batch-type wet pulverizer that can perform pulverization and disintegration into about 1 mm or less or

DESIGN AND FABRICATION OF PULVERIZER MACHINE: A

A pulverizer or grinder is a mechanical device used for the grinding of many different types of materials. The chaff cutter cum pulverizer is a machine which is used for the combine

Design and Development of Pulverizer for Non-Ferric Alum

2018年4月24日Abstract A Pulverizer is a mechanical device for the grinding of different types of materials. Under pulverizer concept we have to select one of types of crusher.

Concrete Pulverizer Demolition Pulverizer Genesis GMP D Series

The GMP D Mechanical Pulverizer processes concrete and rebar with weld-in or patented bolt-in teeth and features an extended link pin position for optimal power. Offset teeth

Mechanical Pulverizers Astec

ConstructionDemolition Recycling (C&D) is mixed material associated with construction and demolition. The material could include , cardboard, plastic, metal, wire, roofing

Mechanical Pulverizer Genesis Attachments

All Genesis Mechanical Pulverizers are covered by a 12-month, 1,500-hour (whichever occurs first) warranty. Shrouded heavy-duty pivot design provides structural strength

(PDF) Development and Performance Evaluation of a Pulverizer

2021年9月6日Design of pulverizer hopper . The hop per is a stainless steel structure, Using ANSYS Mechanical of ANSYS 14.0 software, static . analysis of t he pulverizer’s finite element model (FEM) was .

DESIGN AND FABRICATION OF PULVERIZER MACHINE: A

A pulverizer or grinder is a mechanical device used for the grinding of many different types of materials. The chaff cutter cum pulverizer is a machine which is used for the combine operation of cutting the straw and pulverizing the necessary animal s such as corn, wheat, millet etc. The common components of pulveriser machine are as:

Pulverization 2: Pulverization method and pulverizer

2019年10月31日The rotation and revolution nano-pulverizer is a batch-type wet pulverizer that can perform pulverization and disintegration into about 1 mm or less or even about 100 nm (several dozens of nm by disintegration). It is a type of planetary ball mill (planetary mill) or bead mill.

Design and Development of Pulverizer for Non-Ferric Alum

2018年4月24日Abstract A Pulverizer is a mechanical device for the grinding of different types of materials. Under pulverizer concept we have to select one of types of crusher. Crushers are one of the major size reduction equipment that is used in mechanical, and other different aspect of that type of industries.

IMPROVE YOUR PULVERIZER PERFORMANCE EAPC

One of the most popular pulverizer designs in use today is the medium speed roll and race design, such as B&W™s MPS, Foster Wheeler™s MB or MBF, and ABB-CE™s new HP. require mechanical modification of the throat ring flow area. Minimum throat ring velocity varies with pulverizer design, and even seems to be somewhat proprietary among

Cocoa Pulverising Machine Design, Calculations and Analysis

A pulverizer or machine is a mechanical device for the grinding of many different types of materials. In engineering, Pulverization is defined as the fine crushing of a solid material (to particles of less than 5 mm) In this design however, we make use of beaters or blades, such as is used in blenders, mini home grinders, yam

Applications of Nano Pulverization

2019年11月25日(* Disintegration (= mechanical pulverization) is one of the elements involved in dispersion. To loosen agglomerated particles almost without the formation of new particle surfaces (and to reduce their size) an external mechanical force is applied.) Depending on the pulverizer, the particle size that can be reduced by a single machine

Mechanical Pulverizers Astec

Our EXC Series mechanical concrete pulverizer attachments are designed for quiet, controlled secondary demolition and recycling. Our pulverizers feature bolt-on replaceable teeth that allow field change-out in minutes. The attachment uses existing excavator hydraulics, so no additional circuits are required. Applications

Case: Pulverizer Washington State University

Pulverizer Fred is a mechanical engineer who works for Super Mulcher Corporation. It manufactures the Model 1 Pulverizer, a 10-hp chipper/shredder that grinds yard waste into small particles that can be composted and blended into the soil.

Power Pulverizers

Boilers. To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal

Genesis GMP70C Mechanical Concrete Pulverizer YouTube

Genesis GMP70C Mechanical Concrete Pulverizer 3,474 views Oct 31, 2018 15 Dislike Share Save Jon Fodor 168 subscribers The Genesis GMP C series is specifically designed to provide optimal...

Alstom Pulverizer Catalog.pdf APComPower, Inc.

2013年4月21日pulverizer provides information pertaining to the pulverizer configuration, physical size of the bowl and the type of operating system. The “RB” indicates a steep-sided bowl type of pulverizer that operates under a negative pressure and uses an exhauster fan. Pulverizer Size Base Capacity lbs/hr 312 3,550 352 4,450 412 8,000 473 13,300 533

Coal Pulverizer Power Plant Pall Corporation

The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills.

(PDF) Design of a Pulverizing and Packaging Machine

2018年11月3日The pulverizer and packaging machine were designed using appropriate design equations. From design analysis, the speed of the pulverizer shaft, belt velocity, maximum belt tension and power...

DESIGN AND FABRICATION OF PULVERIZER MACHINE: A

A pulverizer or grinder is a mechanical device used for the grinding of many different types of materials. The chaff cutter cum pulverizer is a machine which is used for the combine operation of cutting the straw and pulverizing the necessary animal s such as corn, wheat, millet etc. The common components of pulveriser machine are as:

IMPROVE YOUR PULVERIZER PERFORMANCE EAPC

One of the most popular pulverizer designs in use today is the medium speed roll and race design, such as B&W™s MPS, Foster Wheeler™s MB or MBF, and ABB-CE™s new HP. require mechanical modification of the throat ring flow area. Minimum throat ring velocity varies with pulverizer design, and even seems to be somewhat proprietary among

Cocoa Pulverising Machine Design, Calculations and Analysis

A pulverizer or machine is a mechanical device for the grinding of many different types of materials. In engineering, Pulverization is defined as the fine crushing of a solid material (to particles of less than 5 mm) In this design however, we make use of beaters or blades, such as is used in blenders, mini home grinders, yam

Applications of Nano Pulverization

2019年11月25日(* Disintegration (= mechanical pulverization) is one of the elements involved in dispersion. To loosen agglomerated particles almost without the formation of new particle surfaces (and to reduce their size) an external mechanical force is applied.) Depending on the pulverizer, the particle size that can be reduced by a single machine

Coal Pulverizer Design Upgrades to Meet the Demands of

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems. The increased use of Low NOX burners in the Most of the first generation design with a mechanical spring grinding force loading system (Figure 2) are still operating today in coal-fired power plants.

Mechanical Pulverizers Astec

Our EXC Series mechanical concrete pulverizer attachments are designed for quiet, controlled secondary demolition and recycling. Our pulverizers feature bolt-on replaceable teeth that allow field change-out in minutes. The attachment uses existing excavator hydraulics, so no additional circuits are required. Applications

Case: Pulverizer Washington State University

Pulverizer Fred is a mechanical engineer who works for Super Mulcher Corporation. It manufactures the Model 1 Pulverizer, a 10-hp chipper/shredder that grinds yard waste into small particles that can be composted and blended into the soil.

Power Pulverizers

Boilers. To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal

Pulverization 2: Pulverization method and pulverizer

2019年10月31日The rotation and revolution nano-pulverizer is a batch-type wet pulverizer that can perform pulverization and disintegration into about 1 mm or less or even about 100 nm (several dozens of nm by disintegration). It is a type of planetary ball mill (planetary mill) or bead mill.

Pulverizers Cat Caterpillar

P224 Secondary Pulverizer. Cycle Time Open. 1.9 s. Cycle Time Close. 1.3 s. Cutting Force Blade Center. 409 Sh Ton. View. Compare models.

Coal Pulverizer Power Plant Pall Corporation

The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills.

Pulverizers 101: Part III POWER Magazine

2011年12月1日Pulverizers prepare raw fuel for burning by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. Part...