iron ore fines and blue dust processing

Effect of Blaine Fineness on the Quality of Hematite Iron

2015年3月4日 In India, during mining and ore processing, ore fine generation is a common phenomenon, in which more than 60% of process ore becomes discarded material. To explore the Three types of ore fines such as hard ore (HO), blue dust (BD) and friable

Iron Ore Pellet Dustiness Part I: Factors Affecting Dust

2015年7月1日 Iron Ore Pellet Dustiness Part I: Factors Affecting Dust Generation, Mineral Processing and Extractive Metallurgy Review, 36:4, 258-266, DOI:

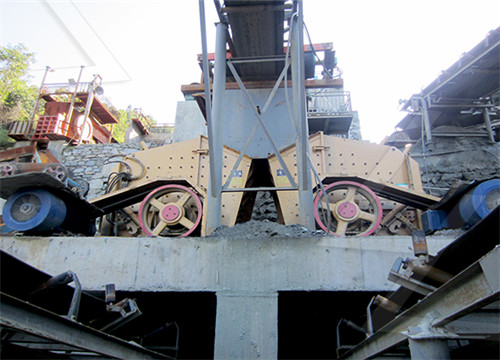

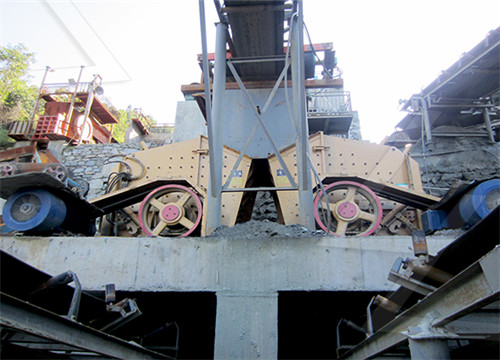

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Iron Ore Processing Flowsheet Grinder Process

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a

iron ore fines and blue dust processing may in swaziland

CARRIAGE OF NICKEL ORE AND IRON ORE FINES Blue dust is a high grade soft hematite ore fines containing more than 96 % Fe2O3 enormously available today. For

iron ore fines and blue dust processing

2020-4-23 Ore Fines and Iron Oxide Wastes Jagannath Pal To cite this article: Jagannath Pal (2019) Innovative Development on Agglomeration of Iron Ore Fines and Iron Oxide

Iron Ore Fines And Blue Dust Processing Aucun-tabou.fr

2021年6月22日 Iron Ore Fines And Blue Dust Processing. The sinter mix besides the ore fines usually contains other materials like flue dust return fines limestone andor dolomite

iron ore fines and blue dust processing Saad

Iron ore pellet feed fines (PFF) The iron ore pelletizing process is,The raw material in the process consists of iron ore ( 100 μm), binders (ie ben-tonite) and additives such as coal

iron ore fines and blue dust processing Allo-pompe

125 Iron And Steel Production Know More. The sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an

Minerals Free Full-Text Geological Controls

2017年10月18日 The blue dust is a deep blue colored, fine powdery, hematitic iron ore containing more than 64% Fe and is considered the best grade of iron ore. Mainly, the iron ores at KMIOD are powdery (blue

Evaluation of VSK separation in the classification of two

2022年12月21日 With gradually diminishing Fe grade in tandem with the ever-increasing demand for high-grade iron ores, iron ore industries are now focusing on the beneficiation of low-grade iron ore fines, mainly considered waste. Besides, the scarcity of water at many of the mines’ sites and the new water conservation policies of the governments have

Investigation on reduction of cement binder in cold

1997年2月1日 Mining and processing of Indian iron ore generate huge amount of fines. Besides, there are huge deposits of naturally occurring iron ore fines (Blue dust) with 60–65% iron content. These fines need to be agglomerated for using as burden material. Cold bonded iron ore pellets with adequate mechanical strength and other characteristics

Iron Ore Rio Tinto

2022年5月28日 Yandicoogina fines. Our Yandicoogina products have a 58% iron content and low impurities, and produce a high-iron sinter. It is used by customers in East Asia and Southern China as the base load in

Plasma Processing of Iron Ore IntechOpen

2020年10月26日 The depletion of high-grade ore minerals and the scarcity of fossil fuel reserves are challenging factors for metallurgical industries in the future. Also, extensive mining for increased steel demand results in the generation of fines often found unsuitable for use as direct feedstock for the production of metals and alloys. Apart from mines

SINTERING AND PELLETISATION OF INDIAN IRON ORES

2020年2月2日 Process objective is to transform fine iron ore concentrate into pellets suitable to feed Blast Furnace or Direct Reduction plant or COREX. Pelletisation was invented to make use of Blue dust and ultra fine concentrate generated in the Iron ore beneficiation plants. Pellets have the benefit of lower gangue on account of

Experimental Studies on Reduction of Coarse Blue Dust for

2019年2月5日 The study reveals that coarse blue dust concentrate can also yield a good quality Iron powder. Key words: Blue dust, Hydrogen, Reduction, Iron powder, Characterisation and Bailadila. INTRODUCTION. Blue dust is a high grade soft hematite ore fines containing more than 90% Fe2O3. This was termed as blue dust due to its

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

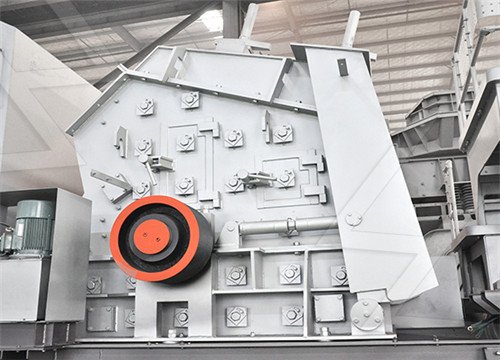

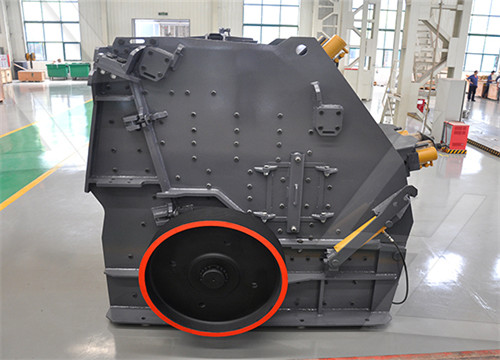

Iron Ore Processing,Crushing,Grinding Plant

Based on the iron ore processing experience and necessary processing tests, Prominer can supply iron ore complete processing plant combined with various processing technologies, such as gravity separation,

Evaluation of VSK separation in the classification of two

2022年12月21日 With gradually diminishing Fe grade in tandem with the ever-increasing demand for high-grade iron ores, iron ore industries are now focusing on the beneficiation of low-grade iron ore fines, mainly considered waste. Besides, the scarcity of water at many of the mines’ sites and the new water conservation policies of the governments have

Innovative Development on Agglomeration of Iron Ore

2018年10月8日 Some of the fines, viz. blast furnace (BF) flue dust, Linz Donawitz (LD) converter sludge etc., are not suitable due to their high alkali and Zn content. Some other material like slime is not considered to be suitable in normal pelletizing practice, because of its high alumina and silica content and excessively fine size.

Iron Ore Agglomeration Technologies

2017年12月20日 Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made

Mineralogical Characteristics of Iron Ores in Joda and

2017年7月18日 Precambrian iron ores of the Singhbhum-North Orissa region occur in eastern India as part of the Iron Ore Group (IOG) within the broad horse-shoe shaped synclinorium. More than 50% of Indian iron ore reserves occur in this region. Massive-hard, flaky-friable, blue dust and lateritic varieties of iron ores are the major ore

Iron Ore Processing,Crushing,Grinding Plant

Based on the iron ore processing experience and necessary processing tests, Prominer can supply iron ore complete processing plant combined with various processing technologies, such as gravity separation,

iron ore fines and blue dust processing Saad

Iron ore pellet feed fines (PFF) The iron ore pelletizing process is,The raw material in the process consists of iron ore ( 100 μm), binders (ie ben-tonite) and additives such as coal dust The moisture of the raw mate-rial can be variable Hybrid Pelletized Sinter (HPS),PM 279 neu:PM 279 E 1...

iron ore fines and blue dust processing Allo-pompe

125 Iron And Steel Production Know More. The sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast furnace The raw materials are sometimes mixed with water to provide a cohesive...

Metso Outotec wins another China iron ore pelletising

2023年3月2日 Iron ore pelletising plants can be more cost-effective compared to traditional iron ore processing plants. Pelletising involves agglomerating iron ore fines into uniform-sized pellets which have several advantages, such as better handling and transportation, reduced dust and emissions, and improved blast furnace performance.

iron ore fines 英中 Linguee词典

2001年10月5日 大量翻译例句关于"iron ore fines" 英中词典以及8百万条中文译文例句搜索。 河北钢铁集团有限公司将按照基于普氏铁 矿 石指 数( 包括铁含量大于62%的铁 矿 石的 额外 溢价)(普氏价格)报的铁 矿 石烧 结上 料粉的每干公吨 月 平均 价格的高于95%的价