lubricants of cone crusher

Proper crusher lubrication Tip of the Week Lube Talk

2018年6月29日 Cone “gyratory” crushers: In a cone crusher, the main shaft is housed in a frame attached to a mantle. A pinion shaft assembly drives a bevel gear that rotates the cone. Oils: As a general rule, operators should use extreme pressure fortified gear

进一步探索Recommended Lubricant For Cone CrusherCrusher Lubrication System OperationMaintenanceCone Crusher Oil System, Dust SealThrust BearingWhich Oil Type Used For Lubrication On Crusher -seedMining tip revisited: Proper crusher lubrication Mobil根据热度为您推荐•反馈

Five steps to optimize crusher’s lubrication system Metso

2018年7月30日 At minimum, lube system maintenance checks, inspections or servicing must include the following steps: 1. Monitoring of lube oil temperature. A lot can be

预计阅读时间:4 分钟

Robco Inc. Robco Cone Crusher Lubricant

2023年2月4日 With Robco cone grease, large coal mines can save $ 175,000 per year in crusher maintenance costs.. Case Study: A mining customer had to replace a damaged

预计阅读时间:1 分钟

How to Choose the Lubricating Oil of Hydraulic Cone

2022年2月9日 For the components of the cone crusher, parts that work under heavy loads require a more viscous lubricant. For example, when the bearing pressure is large, the oil

Crusher Lubricant™ ISO 220 Products D-A Lubricant

Crusher Lubricant™ ISO 220. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and

预计阅读时间:40 秒

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and

How to do the lubrication of the cone crusher-Jiaozuo

2021年5月6日 It is very necessary to keep the lubrication system's oil path unblocked, clean, non-leaking, and normal operation to ensure the work of the crusher. 1. Lubricants

lubricants for cone crushers

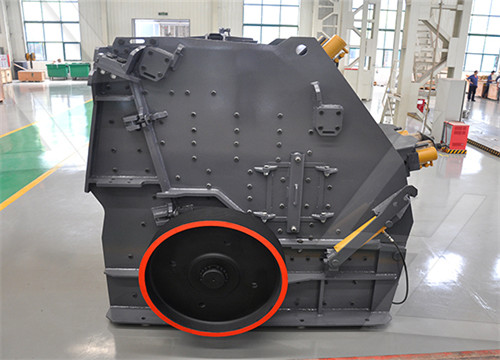

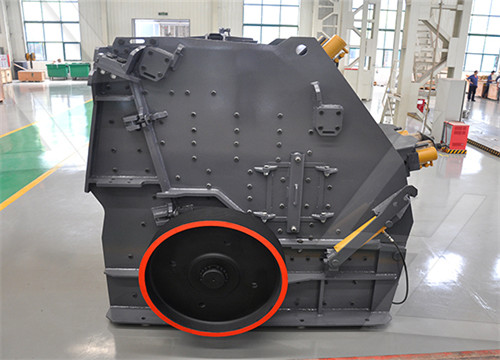

<C6X Series Jaw Crusher> lubricants for cone crushers. Double wedge adjusting device, Elastic limit damping device. C6X Jaw Crusher is new equipment used for crushing hard

lubricants of cone crusher

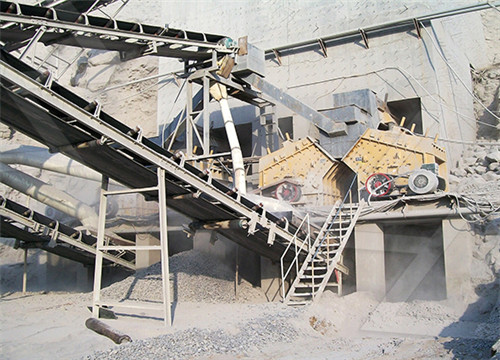

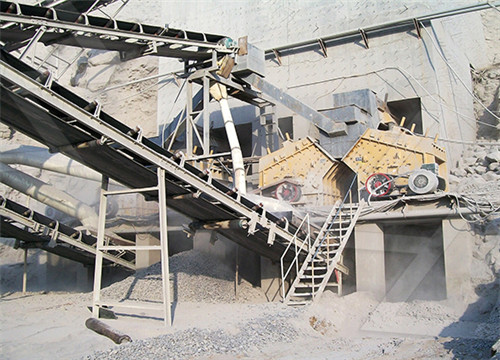

Introduction to the processing technology system of the jaw crusher production line. Jaw crushers usually do not work independently, but together with cone crushers, impact

Cone Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 8.2). Power is transmitted from the source to the countershaft to a V-belt or direct drive.

How to Choose the Lubricating Oil of Hydraulic Cone

2022年2月9日 For the components of the cone crusher, parts that work under heavy loads require a more viscous lubricant. For example, when the bearing pressure is large, the oil is pressed out from the bearing and then operated in a dry state, which tends to generate a high working temperature, so a more viscous lubricating oil is used.

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and quality of lubricants. Insufficient quantity should be replenished in time, and poor quality should be replaced in time. The cone crusher adopts thin oil circulation lubrication.

Cone Crushers Moore Watson Ltd

Brief Introduction. MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners. The MP Cone Crusher is advanced in design, more compact with a higher

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries. Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically.

Cone Crusher Parts Mineral Processing

2017年2月19日 The lubricant is sealed in with a garter type oil seal. Bearings can be lubricated from outside the topshell on the 51, 60 and 84-in. crushers through oil holes in spider caps of the four smaller sizes. Cone

14 Cone Crusher Common Problems And How

Solution: Correct meshing clearance or replace gear. 13. The supporting ring jumps. Cause: Non-fragments fall into the crushing chamber, and the main shaft is easy to break. Solution: Strengthen iron pick-up or install

4 Types of Stone Crushers' Maintenance and

2023年2月15日 Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures medium-hard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher

Cone Crusher Lubrication Tank Oil for All Types Of Cone

Baton Consultants Private Limited Offering Cone Crusher Lubrication Tank Oil for All Types Of Cone Crushers, Lubricant Can at Rs 115/litre in Thane, Maharashtra. Check best price of Lubricants in Thane offered by verified suppliers with contact number ID:

en/impact crushers lubricants.md at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub.

Gyratory and Cone Crusher ScienceDirect

2016年1月1日 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and quality of lubricants. Insufficient quantity should be replenished in time, and poor quality should be replaced in time. The cone crusher adopts thin oil circulation lubrication.

How to choose the right cone crusher lubricant? Failure

2019年8月22日 First, different season with the different lubricant. 1. The temperature from winter to spring is relatively cold, it is recommended to use relatively slippery lubricating oil; most of the autumn

The pros and cons of cone crusher applications Quarry

2021年4月16日 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per

Cone Crushers Moore Watson Ltd

Brief Introduction. MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners. The MP Cone Crusher is advanced in design, more compact with a higher

[PDF]

For Cone Drive Double Enveloping Worm Speed

2022年3月8日 Approved List of Lubricants . For Cone Drive Double Enveloping Worm Speed ReducersGearsets . ve Operations, Inc. 240 E. 12. th. Street, P.O. Box 272, Traverse City, MI 49685-0272 USA Phone: 231-946-8410, Fax 231-933-8600 conedrive Sales Phone: 888-994-2663 Sales Fax: 888-907-2663 .

Cone Crusher Lubrication Tank Oil for All Types Of Cone

Baton Consultants Private Limited Offering Cone Crusher Lubrication Tank Oil for All Types Of Cone Crushers, Lubricant Can at Rs 115/litre in Thane, Maharashtra. Check best price of Lubricants in Thane offered by verified suppliers with contact number ID:

Jaw Crusher Lubrication Knowledge Analysis 2019-09-10

2019年9月10日 The elbow of the thrust plate is lubricated with thick oil and needs to be lubricated every 3-4h. 4, the temperature of lubrication. There is also the temperature of the jaw crusher lubricant, we must also pay attention. In the use of the jaw crusher thin oil system, the temperature of the oil return should not exceed 60 degrees.

lubricants of cone crusher

Introduction to the processing technology system of the jaw crusher production line. Jaw crushers usually do not work independently, but together with cone crushers, impact crushers, sand making machines, vibrating screens, etc., constitute a complete set of sand and gravel processing systems to achieve accurate processing of ore and rock and

Cone Crusher at Best Price in India IndiaMART

Cone Crusher, Automatic Grade: Automatic. ₹ 35 Lakh Get Latest Price. Type Of Crushing Machines: Cone Crusher. Capacity: Available in 3 variants of capacities from 100-300 (t/h) Automation Grade: Automatic. Feed Capacity (mm): Upto 200 mm. Material Handled: Dolomite, Stone, Limestone, Graphite, Slag, Iron ore, Coal.

Five steps to optimize crusher’s lubrication system Metso

2018年7月30日 At minimum, lube system maintenance checks, inspections or servicing must include the following steps: 1. Monitoring of lube oil temperature. A lot can be

Robco Inc. Robco Cone Crusher Lubricant

2023年2月4日 With Robco cone grease, large coal mines can save $ 175,000 per year in crusher maintenance costs.. Case Study: A mining customer had to replace a damaged

How to Choose the Lubricating Oil of Hydraulic Cone

2022年2月9日 For the components of the cone crusher, parts that work under heavy loads require a more viscous lubricant. For example, when the bearing pressure is large, the oil

Crusher Lubricant™ ISO 220 Products D-A Lubricant

Crusher Lubricant™ ISO 220. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and

How to do the lubrication of the cone crusher-Jiaozuo

2021年5月6日 It is very necessary to keep the lubrication system's oil path unblocked, clean, non-leaking, and normal operation to ensure the work of the crusher. 1. Lubricants

lubricants for cone crushers

<C6X Series Jaw Crusher> lubricants for cone crushers. Double wedge adjusting device, Elastic limit damping device. C6X Jaw Crusher is new equipment used for crushing hard

lubricants of cone crusher

Introduction to the processing technology system of the jaw crusher production line. Jaw crushers usually do not work independently, but together with cone crushers, impact

Cone Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 8.2). Power is transmitted from the source to the countershaft to a V-belt or direct drive.

How to Choose the Lubricating Oil of Hydraulic Cone

2022年2月9日 For the components of the cone crusher, parts that work under heavy loads require a more viscous lubricant. For example, when the bearing pressure is large, the oil is pressed out from the bearing and then operated in a dry state, which tends to generate a high working temperature, so a more viscous lubricating oil is used.

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and quality of lubricants. Insufficient quantity should be replenished in time, and poor quality should be replaced in time. The cone crusher adopts thin oil circulation lubrication.

Cone Crushers Moore Watson Ltd

Brief Introduction. MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners. The MP Cone Crusher is advanced in design, more compact with a higher

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries. Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically.

Cone Crusher Parts Mineral Processing

2017年2月19日 The lubricant is sealed in with a garter type oil seal. Bearings can be lubricated from outside the topshell on the 51, 60 and 84-in. crushers through oil holes in spider caps of the four smaller sizes. Cone

14 Cone Crusher Common Problems And How

Solution: Correct meshing clearance or replace gear. 13. The supporting ring jumps. Cause: Non-fragments fall into the crushing chamber, and the main shaft is easy to break. Solution: Strengthen iron pick-up or install

4 Types of Stone Crushers' Maintenance and

2023年2月15日 Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures medium-hard or hard rocks like pebble, quartz, granite, etc. It is easy to get premature crusher

Cone Crusher Lubrication Tank Oil for All Types Of Cone

Baton Consultants Private Limited Offering Cone Crusher Lubrication Tank Oil for All Types Of Cone Crushers, Lubricant Can at Rs 115/litre in Thane, Maharashtra. Check best price of Lubricants in Thane offered by verified suppliers with contact number ID:

en/impact crushers lubricants.md at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub.

Gyratory and Cone Crusher ScienceDirect

2016年1月1日 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

How to do the lubrication of the cone crusher_Jiaozuo

2021年5月7日 In use, neither low-grade lubricants nor other types of lubricants can be used instead, and inferior products should not be used. 2. Always check the quantity and quality of lubricants. Insufficient quantity should be replenished in time, and poor quality should be replaced in time. The cone crusher adopts thin oil circulation lubrication.

How to choose the right cone crusher lubricant? Failure

2019年8月22日 First, different season with the different lubricant. 1. The temperature from winter to spring is relatively cold, it is recommended to use relatively slippery lubricating oil; most of the autumn

The pros and cons of cone crusher applications Quarry

2021年4月16日 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per

Cone Crushers Moore Watson Ltd

Brief Introduction. MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners. The MP Cone Crusher is advanced in design, more compact with a higher

For Cone Drive Double Enveloping Worm Speed

2022年3月8日 Approved List of Lubricants . For Cone Drive Double Enveloping Worm Speed ReducersGearsets . ve Operations, Inc. 240 E. 12. th. Street, P.O. Box 272, Traverse City, MI 49685-0272 USA Phone: 231-946-8410, Fax 231-933-8600 conedrive Sales Phone: 888-994-2663 Sales Fax: 888-907-2663 .

Cone Crusher Lubrication Tank Oil for All Types Of Cone

Baton Consultants Private Limited Offering Cone Crusher Lubrication Tank Oil for All Types Of Cone Crushers, Lubricant Can at Rs 115/litre in Thane, Maharashtra. Check best price of Lubricants in Thane offered by verified suppliers with contact number ID:

Jaw Crusher Lubrication Knowledge Analysis 2019-09-10

2019年9月10日 The elbow of the thrust plate is lubricated with thick oil and needs to be lubricated every 3-4h. 4, the temperature of lubrication. There is also the temperature of the jaw crusher lubricant, we must also pay attention. In the use of the jaw crusher thin oil system, the temperature of the oil return should not exceed 60 degrees.

lubricants of cone crusher

Introduction to the processing technology system of the jaw crusher production line. Jaw crushers usually do not work independently, but together with cone crushers, impact crushers, sand making machines, vibrating screens, etc., constitute a complete set of sand and gravel processing systems to achieve accurate processing of ore and rock and

Cone Crusher at Best Price in India IndiaMART

Cone Crusher, Automatic Grade: Automatic. ₹ 35 Lakh Get Latest Price. Type Of Crushing Machines: Cone Crusher. Capacity: Available in 3 variants of capacities from 100-300 (t/h) Automation Grade: Automatic. Feed Capacity (mm): Upto 200 mm. Material Handled: Dolomite, Stone, Limestone, Graphite, Slag, Iron ore, Coal.