copper mining control process

Copper: Automation, IsolationControls Bray

Copper mining and concentrates production is a complex process requiring a symphony of operations using specialized equipment and techniques such as explosives and earth moving equipment to extract and transport the raw ore to the processing plant for

Copper Mining and Processing: Processing Copper Ores

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling Copper

Oxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leachingis the process of using percolating chemical solutions to leach out meta...

Advanced process control in mining ABB

APC manages blending, grinding and flotation in real-time. Geological models and real-time material tracking provide a short-term feed characteristic schedule to the APC so it can

ABB process control and automation solutions

ABB is uniquely positioned to bring together industrial enterprise software spanning process control, production management, operational planning and optimization, work and asset management and backoffice corporate

Copper Mining and Processing: Everything you Need to

2022年8月1日 The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and

Copper Mining and Processing: Life Cycle of a Mine

19 小时之 Prospecting and exploration are precursors to mining and often occur simultaneously; together, they can take two to eight years to complete, and may cost

minerals Sensors and Process Control in Copper Smelters:

2020年12月22日 Adiabatic temperature of the reactive system during smelting (oxidation process) of concentrates 1 and 2 (Table 1). The enriched air for the process has 65% O

KAZ Minerals Focused on copper

The copper mining process. KAZ Minerals operates six producing mines. The three mines in East Region are underground while the Bozshakol, Aktogay and Bozymchak mines are

Copper Ore Processing Methods Metallurgist

2017年4月11日 Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

Copper Mining and Extraction Copper Mining

2022年11月16日 Copper is extracted in large amounts from the Earth’s crust by mining of sulphide ores and also oxide ores. Studies reveal about 80% of copper is produced by its extraction from sulphide ores.

Processing of Complex Materials in the Copper

2020年7月6日 A global copper mine-by-mine review undertaken by ICSG found that the global average copper ore grade was as low as 0.45% copper in reported reserves and only 0.65% copper in 2015 copper mine

Automating and Optimizing Copper Heap

2021年3月17日 That’s why I wanted to revisit the 2018 Mining Engineering magazine article, Improved flow measurement and control are key to efficiency, by Emerson’s Alena Johnson. Alena opens describing the

Creating the zero-carbon mine McKinsey

2021年6月29日 The mining industry is at a tipping point where sustainability and decarbonization are top items on CEOs’ agendas. To achieve a 1.5°C climate-change target by 2050, the mining industry will

Copper Mining and Processing: Life Cycle of a Mine

19 小时之 Prospecting and exploration are precursors to mining and often occur simultaneously; together, they can take two to eight years to complete, and may cost from $500,000 to $15 million overall. Prospecting is the process of searching the region for mineral deposits. Historically, prospectors would explore a region on foot with a pick and

Newmont Corporation About Us About Mining The

The Mining Process. Finding new mineral reserves is critical to the success of our company. Locating, extracting and processing these natural resources is a multi-year process that involves complex scientific, environmental and social planning. Newmont mission is to build a sustainable mining business while leading in safety, environmental

Copper Processing Multotec

Copper processing begins with mining copper ore, which contains less than 1% of copper, and ends with sheets of 99.99% pure copper (cathodes). Copper mining generally takes place through open-pit mining, in which a series of stepped benches are dug deeper into the earth. Yet, it can also be mined underground, through horizontal tunnels.

Copper Ore Processing Methods Metallurgist

2017年4月11日 Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

Chapter 8 Environmental Aspects of Copper Production

1996年11月20日 the 1980 Copper Strike, ”Journal of Air Pollution Control, vol. 33,. though fossil-fueled electric powerplants are the major source of S0 2 emissions in the United States, smelters contribute significantly to total emissions in the sparsely popuIated copper-pro-ducing areas of the West (see table 8-l). Fugitive emissions from furnaces and

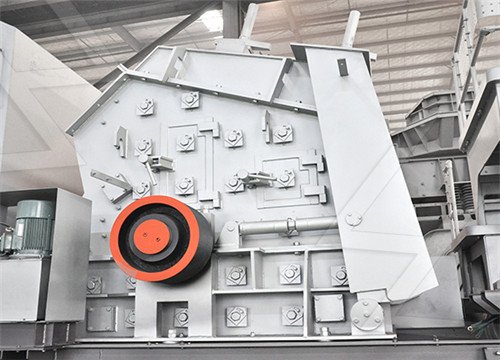

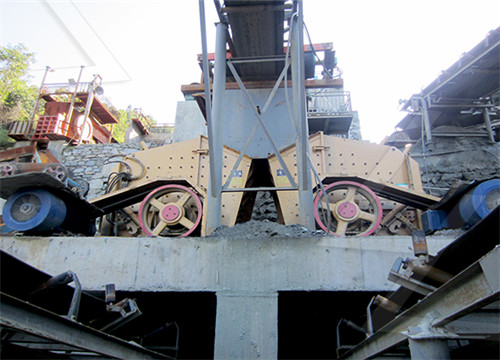

Copper Mining Equipment ProductsSuppliers

Description: Thinking big with Lokotrack LT200E Features Altay Polimetally LLP will open a new copper mine in Kazakhstan during 2015. Metso provides the world’s biggest mobile jaw crushing plant to meet the mine’s capacity requirement. The plant consists of mobile apron Industry or Material Processed: Mining / Ores / Minerals; Process Type: Dry

Automating and Optimizing Copper Heap

2021年3月17日 That’s why I wanted to revisit the 2018 Mining Engineering magazine article, Improved flow measurement and control are key to efficiency, by Emerson’s Alena Johnson. Alena opens describing the

Creating the zero-carbon mine McKinsey

2021年6月29日 The mining industry is at a tipping point where sustainability and decarbonization are top items on CEOs’ agendas. To achieve a 1.5°C climate-change target by 2050, the mining industry will

Copper Processing Multotec

Copper processing begins with mining copper ore, which contains less than 1% of copper, and ends with sheets of 99.99% pure copper (cathodes). Copper mining generally takes place through open-pit mining, in which a series of stepped benches are dug deeper into the earth. Yet, it can also be mined underground, through horizontal tunnels.

Copper Mining and Extraction Copper Mining

2022年11月16日 Copper is extracted in large amounts from the Earth’s crust by mining of sulphide ores and also oxide ores. Studies reveal about 80% of copper is produced by its extraction from sulphide ores.

Project Overview Resolution Copper

In 2004, Resolution Copper Mining assumed control of the Magma Mine site. Resolution Copper started the US permitting process in 2013, and since the US Forest Service (USFS) has conducted a comprehensive independent review under the National Environmental Policy Act (NEPA). Following a rigorous and lengthy permitting process, a decade of

Copper ProcessingHandling Equipment FEECO

Pug mills are a key piece of equipment in the copper smelting process, serving to mix and condition several components (copper concentrate, flux, reverts, matte recycle, and dust recycle), for reintroduction into the smelter.. Bulk Material Handling. In addition to our pug mills and ore drums, FEECO can supply the necessary bulk material handling equipment

Underground Mining Methods of Copper

2017年4月17日 Underground Mining-Auxiliary to Steam-Shovel Operations. As is generally known the Utah Copper mine is primarily a steam-shovel operation, and it will perhaps surprise many that up to

The White House moves to ban copper mining near

2021年10月28日 That process begins with an environmental study that could lead to a 20-year mining ban in the area. But not all canoe outfitters support the move. DAN WATERS: I am in favor of mining if it can be

Bwalya Musonda (MAusiMM) Resource Geologist

Bwalya is a professional Geologist experienced in both open cut and Underground Mining environment. I have an in-depth understanding of the mine to mill reconciliation process, Grade Control, Production, data validation, creation and management of databases, QA/QC protocols, wireframing and End of month Reporting. Bwalya has been exposed to

12.3 Primary Copper Smelting US EPA

2015年9月10日 Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. 12.3.2 Process Description2-4 Mining produces ores with less than 1 percent copper. Concentration is accomplished at the mine sites by crushing, grinding, and flotation purification, resulting in ore with 15 to 35 percent