iron ore benifi ion plant

Treatment of iron ore beneficiation plant process water by

2021年1月1日As a result, most of the iron ore beneficiation plant faces difficulty in discharging large volumes of water as well as a shortage of fresh water to operate the plant. Hence, suitable treatment technologies needs to be explored to operate iron ore

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. DOWNLOAD From Canada’s Labrador Trough region, across India, Brazil and

Iron Ore Beneficiation Primetals Technologies

Fig.1- Design of a modular tailings beneficiation plant. Fig. 2- Iron ore tailings dam; a future resource for iron making. Fig.3 Hybrid Flotation Cell. Fig. 4- Dewatered tailings as stack pile for safe tailing storage. Fig. 5-

10 Best Ore Beneficiation Plants for Sale (with Costs)

01 Case site 5 TPH low-grade gold ore beneficiation plant in India. 5 TPH. Raw material.

Simec Mining 950tph Iron Ore Beneficiation Wash Plant CDE

The plants beneficiate a low-grade ore that was historically considered waste material. This is achieved by removing silica and alumina from the feed material, as well as gravity

Treatment of iron ore beneficiation plant process water by

2020年11月1日Process water collected from the iron ore beneficiation plant was treated by electrocoagulation (EC) process to make it suitable for reuse or safe for discharge.

Beneficiation of Iron Ores IspatGuru

2014年4月3日Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日Beneficiation of Iron Ore treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a

Iron ore Beneficiation Plant FTM Machinery

Generally, after the processing of beneficiation, the purity of iron ore is about 60%, the copper ore is about 25% , and the cobalt ore is about 20%. 3.Finishing work. After the

GLOBAL EXPRESSION OF INTEREST (EOI) FOR BUSINESS CO

Iron Ore Beneficiation Plant ‐ Details as given in Annexure‐I 2. Pellet Plant ‐ Details as given in Annexure‐II Due date for submission of EOI along with duly filled in documents,

Treatment of iron ore beneficiation plant process water by

2021年1月1日Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant followed by settling and filtration. It is observed from the results that the concentration of total Fe, Cr, Pb, Mn and turbidity are found to be 115.24 mg/L, 7.10 mg/L, 2.68 mg/L, 0.96

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. DOWNLOAD From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in

Iron Ore Beneficiation Primetals Technologies

IRON ORE BENEFICIATION — FROM NATURAL RESOURCES TO VALUABLE PRODUCTS Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality

Existing and New Processes for Beneficiation of Indian Iron ores

2020年2月8日The beneficiation techniques such as scrubbing, classification, gravity separation, magnetic separation and flotation are generally utilized to enhance the quality of the iron ores. In India, beneficiation is carried out

(PDF) An overview of the beneficiation of iron ores

2014年3月1日Flotation is the most effective solution, both technologically and economically, when upgrading iron concentrates. Research regarding iron ore flotation began in 1931, demonstrating that...

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1.3 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000. Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton (the latter two companies having two head offices, in the UK and Australia), now account for approximately 65% of the iron ore traded across the world.

Iron Ore Beneficiation Mineral Processing

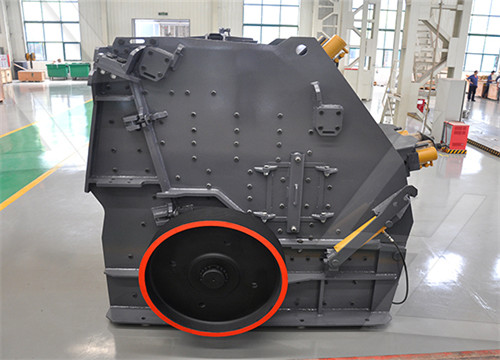

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), and mineral dehydration

Iron ore Beneficiation Plant FTM Machinery

What is iron ore beneficiation plant? According to different physical and chemical properties of the ore, using the gravity method, flotation method, and magnetic separation method to separate useful minerals from crushed gangue minerals and decrease harmful impurities in the beneficiation process.

GLOBAL EXPRESSION OF INTEREST (EOI) FOR BUSINESS CO

Iron Ore Beneficiation Plant ‐ Details as given in Annexure‐I 2. Pellet Plant ‐ Details as given in Annexure‐II Due date for submission of EOI along with duly filled in documents, as applicable is 28 April 2014.

700TPH Iron Ore Wash Beneficiation Plant in Australia YouTube

This 700TPH iron ore wash beneficiation plant in South Australia was designed to beneficiate extremely abrasive haematite held in stockpiles of low-grade iron ore which has accumulated over...

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日For an integrated DR plant, an ore beneficiation and scrap upgrading according to the example results in a total saving of 24 USD/t steel when the Si tot in scrap and SiO 2 in DRI are reached to 0.5% and 2%, The loss of iron units in ore beneficiation is compensated for with higher savings in the EAF together with reduced consumption of

Iron Ore Beneficiation Process MetallurgistMineral

2017年4月27日At this time four of the above methods of beneficiation, i. e., Drying, Screening, Log Washing, and Table Concentration are in use, and a plant for a fifth process, magnetic concentration, is now under construction. Drying plants may be seen at the Brunt mine, at Mountain Iron, and at the Whiteside mine, at Buhl, the latter being inactive at

Andries Wessels Iron Ore Plant Operator Anglo American

Experienced Plant Operator with a demonstrated history of working in the miningmetals industry. Skilled in Occupational Health, English, Teamwork, Metals, and Environment, Health, and Safety (EHS). Strong operations professional with a National Certificate focused in Mineral Processing : Lump Ore Beneficiation from MQA : Mining

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日For an integrated DR plant, an ore beneficiation and scrap upgrading according to the example results in a total saving of 24 USD/t steel when the Si tot in scrap and SiO 2 in DRI are reached to 0.5% and 2%, The loss of iron units in ore beneficiation is compensated for with higher savings in the EAF together with reduced consumption of

Treatment of iron ore beneficiation plant process water by

2021年1月1日Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant followed by settling and filtration. It is observed from the results that the concentration of total Fe, Cr, Pb, Mn and turbidity are found to be 115.24 mg/L, 7.10 mg/L, 2.68 mg/L, 0.96

Iron Ore Beneficiation Primetals Technologies

IRON ORE BENEFICIATION — FROM NATURAL RESOURCES TO VALUABLE PRODUCTS Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality

The Chinese Iron Ore Deposits and Ore Production

2018年7月11日Anshan Iron and Steel Mining Company, Qidashan iron plant and Gongchangling beneficiation plant conducted flotation tailings re-separation pilot study. The results show that the pre-enrichment of

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1.3 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000. Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton (the latter two companies having two head offices, in the UK and Australia), now account for approximately 65% of the iron ore traded across the world.

Iron Ore Beneficiation Mineral Processing

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), and mineral dehydration

Iron Ore Beneficiation Process Metallurgist

2017年4月27日By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and moisture. The

700TPH Iron Ore Wash Beneficiation Plant in Australia YouTube

2021年6月23日This 700TPH iron ore wash beneficiation plant in South Australia was designed to beneficiate extremely abrasive haematite held in stockpiles of low-grade iron ore which has accumulated over...

Iron ore Beneficiation Plant FTM Machinery

What is iron ore beneficiation plant? According to different physical and chemical properties of the ore, using the gravity method, flotation method, and magnetic separation method to separate useful minerals from crushed gangue minerals and decrease harmful impurities in the beneficiation process.

GLOBAL EXPRESSION OF INTEREST (EOI) FOR BUSINESS CO

Iron Ore Beneficiation Plant ‐ Details as given in Annexure‐I 2. Pellet Plant ‐ Details as given in Annexure‐II Due date for submission of EOI along with duly filled in documents, as applicable is 28 April 2014.

Samarco Iron Ore Mine, Alegria, Brazil Mining

2000年3月22日At the Germano beneficiation plant the ore is screened, crushed and classified to feed the primary mills. This circuit assures sufficient reduction of the iron ore particles. At 396km, this iron ore

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017年2月1日In general, iron ore beneficiation is done at the mining site. The concentrated iron ore is subsequently sintered or pelletized, depending on the grain size distribution, before it is charged to an ironmaking plant. In cases where after the initial processing steps the iron ore fractions are of inferior quality (too fine or low iron content

Titanium Beneficiation Plant Mineral Processing

Type of titanium. Rock ore titanium: Rock ore is mainly titanium-containing composite iron ore, which has a dense structure and is difficult to mine and select. Through multi-stage crushing and screening, gravity separation, magnetic separation, electric separation and less flotation are used to improve the TiO2 grade of titanium ore.. Alluvial ore titanium: The

Andries Wessels Iron Ore Plant Operator Anglo American

Experienced Plant Operator with a demonstrated history of working in the miningmetals industry. Skilled in Occupational Health, English, Teamwork, Metals, and Environment, Health, and Safety (EHS). Strong operations professional with a National Certificate focused in Mineral Processing : Lump Ore Beneficiation from MQA : Mining