attrition scrubber grinding

Attrition scrubbing for recovery of indium from waste liquid

2017年6月15日The mechanism of fracture in attrition scrubbing is illustrated in Fig. 2. Download : Download high-res image (181KB) Download : Download full-size image; Fig.

Attrition Cells/Scrubbers McLanahan

Attrition Cells/Scrubbers are designed to scrub the surfaces of particulates, liberate deleterious materials and break down pretend particulates associated with durability, such as hard-pan clays.

Attrition Scrubber GTEK

The most important function of the attrition machine is the scrubbing of particle surfaces to remove film or coating. GTEK’s versatile attrition scrubber is specially developed for a vast range of applications: 1.

Attrition Scrubber Sepor, Inc

Attrition Scrubber Request PricingInfo Description Intensively mixes and scrubs mineral products. Propellers and shaft, tanks are welded of mild steel and available with urethane, rubber, or neoprene linings. Available in

Attrition Scrubbers JXSC Machine

The most important function of the attrition machine is the scrubbing of particle surfaces to remove film or coating. Attrition Scrubber Working Principle: The motor drives the main

Attrition Scrubbers Westpro Machinery

The scrubber tanks and mechanisms are designed to produce intense agitation and deliver superior scrubbing performance. PROVIDING THE LARGEST ATTRITION SCRUBBER

Silica Sand ProcessingSand Washing Plant Equipment

2016年5月9日ATTRITION SCRUBBING From classification the sand, at 70 to 75% solids, is introduced into a Attrition Scrubber for removal of surface stain from the sand grains. This is done by actual rubbing of the

Attrition Scrubbers Eagle Iron Works

Eagle Iron Works’ Attrition Scrubbers are designed for high-intensity, grain-on-grain scrubbing. Eagle Iron Works Attrition Scrubbers are designed for long service life and ease of maintenance. Parts that

Attrition scrubbing for recovery of indium from waste liquid

2017年6月15日Attrition scrubbers have been used in mineral processing of certain ores for some time, but have found unique applicability in soil remediation operations to impart high shear on particle surfaces thereby liberating surface contaminants ( Spiller, 1992 ).

SAG Mill Autogenous and Semi-Autogenous Mills

WEMCO® Attrition Scrubber Back. Column flotation cells. Column Flotation Cell Smart Flotation Back. Forced air flotation cells. Forced-Air Wear Parts Semi-autogenous grinding uses a minimal ball charge in the range of

Attrition Scrubbers Westpro Machinery

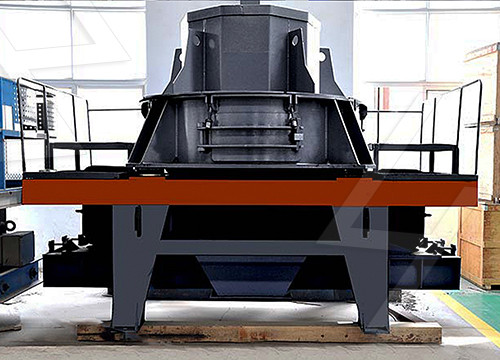

Attrition Scrubbers. Westpro’s versatile attrition scrubbers provide efficient slurry scrubbing solutions for applications in a variety of industries including mining, frac sands, aggregates and soil remediation. The scrubber tanks and mechanisms are designed to produce intense agitation and deliver superior scrubbing performance.

Attrition Scrubbers Eagle Iron Works

A constant feed of material to the Attrition Scrubbers is necessary for the most efficient attrition possible; the rate of discharge from the Attrition Scrubbers is directly dependent upon the feed to the machine. For the most efficient abrading action, the feed slurry entering the machine should be maintained at 65% to 85% solids.

Used Attrition Scrubbers for sale. Metso equipmentmore

Attrition scrubber, 2-cell, Svedala/Metso, model 32X32-2 cell, serial number , 0603-07, chamber measures 32" X 32" X 36" deep, steel tank. Includes 15 HP, 3 phase, 230/460 V, Frame 286T, 875 RPM motor. Grinding machines; Heavy Duty Lathes; Honing machines; Laser Cutters; Lathes; Machining Centers; Metal Rolling; Metalworking

Attrition Scrubbers MIP Process Technologies (Pty) Ltd

The MIP Process Technologies (Pty) Limited attrition scrubber is a culmination of more than fifteen (15) years of experience in this field. The attrition scrubber operates on the principle of creating more attritioning zones within the machine. Our unit is designed with multiple blades, instead of only two, thus creating numerous attritioning

Attrition Scrubber Attrition Machine Attrition Cell Silica

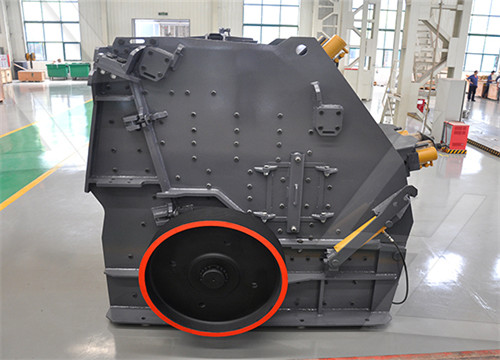

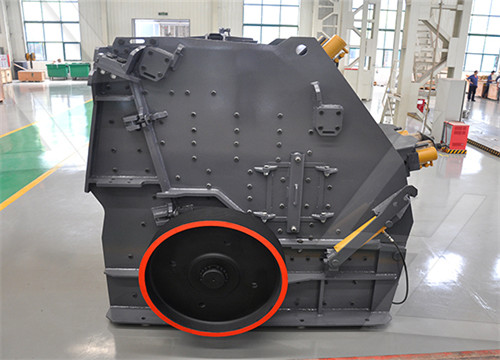

Description Attrition scrubbing is the process where a mineral is scrubbed primarily by the action of the slurry particles impacting one another. Attrition scrubbers, also known as Attrition Cells, are relatively simple devices. They consist of a

Attrition Scrubber, Mixing mining equipment, Mixing

Alternatively, the attrition scrubbers may be configures in the standard method (open flow), with cells in line and flow between the cells. Gear reducers provide the ideal speed for each diameter propeller and are totally enclosed and running in oil design.

China GCX Attrition Scrubber Manufacturers and Suppliers

GCX attrition scrubber is a scrubbing equipment that needs no medium, which mainly consists of reducer driving system, polygonal tank and turbine blades agitator. For scrubbing and polishing minerals without grinding media. Inclined straight and even number blades, and adjacent ones with opposite inclination angles.

A methodology to liberate critical metals in waste solar panel

The trial of a five minutes attrition scrubbing shows that grinding can be solution to de-coat the critical metals as the second stage recycling process. 86.26 w% of indium can be concentrated in 13.7 g fine particle with the concentration of 1506 ppm but it can be improved by adjusting the operating condition. Attrition scrubber (Fagergren

USB2 Attrition scrubber apparatus and method Google

An attrition scrubber that includes multiple attrition scrubber cells. The multiple attrition scrubbers cells are arranged generally parallel to a vertical axis of rotation. The apparatus includes a shaft that extends generally parallel to the vertical axis of rotation and through the center of all attritioning cells. Each attritioning cell contains two impellers having a diameter.

Improvement in product of silica plant by modification of size

2014年10月20日Using sodium carbonate during attrition scrubbing, has major effect on removal of surface coating and staining especially sharp increase in clay removal; therefore 2 kg/t of sodium carbonate can...

Attrition scrubbers/cells-Sinonine

Efficient attrition scrubbing removes unwanted contaminants, impurities, surface films, coatings, clays or slime, designed to achieve the strongest possible scrubbing to improve mineral values and create a more desired product, without damaging or degrading the recovered particles. Applications for attrition scrubbers

Attrition scrubbing for recovery of indium from waste liquid

2017年6月15日Attrition scrubbers have been used in mineral processing of certain ores for some time, but have found unique applicability in soil remediation operations to impart high shear on particle surfaces thereby liberating surface contaminants ( Spiller, 1992 ).

Attrition Scrubbers Westpro Machinery

The scrubber tanks and mechanisms are designed to produce intense agitation and deliver superior scrubbing performance. PROVIDING THE LARGEST ATTRITION SCRUBBER IN OPERATION: AS108 AS24VB-4 ( 40ft³ ) Attrition Scrubber fully assembled at the Westpro Shop Let our Process Engineer size it for you!

Attrition Scrubbers Eagle Iron Works

A constant feed of material to the Attrition Scrubbers is necessary for the most efficient attrition possible; the rate of discharge from the Attrition Scrubbers is directly dependent upon the feed to the machine. For the

Attrition Scrubbers Sepor, Inc

Attrition Scrubbers Description: Catalog Number 080C SEPOR’s attrition scrubbers range in size from 1 to 3 cubic foot cells, with up to four cells per bank. This size range is particularly suitable for pilot plant

Used Attrition Scrubbers for sale. Metso equipmentmore

Attrition scrubber, 2-cell, Svedala/Metso, model 32X32-2 cell, serial number , 0603-07, chamber measures 32" X 32" X 36" deep, steel tank. Includes 15 HP, 3 phase, 230/460 V, Frame 286T, 875 RPM motor. Grinding machines; Heavy Duty Lathes; Honing machines; Laser Cutters; Lathes; Machining Centers; Metal Rolling; Metalworking

Rotary Scrubbers for coarse minerals liberation and

With supplied scrubber diameters up to 7.33m, we have a well established range of scrubbers to suit all applications. We have the ability to custom design our solutions to suit your application whether it’s washing of

Attrition Scrubbers MIP Process Technologies (Pty) Ltd

The MIP Process Technologies (Pty) Limited attrition scrubber is a culmination of more than fifteen (15) years of experience in this field. The attrition scrubber operates on the principle of creating more attritioning zones within the machine. Our unit is designed with multiple blades, instead of only two, thus creating numerous attritioning

Attrition Scrubber, Mixing mining equipment, Mixing

Alternatively, the attrition scrubbers may be configures in the standard method (open flow), with cells in line and flow between the cells. Gear reducers provide the ideal speed for each diameter propeller and are

A methodology to liberate critical metals in waste solar panel

The trial of a five minutes attrition scrubbing shows that grinding can be solution to de-coat the critical metals as the second stage recycling process. 86.26 w% of indium can be concentrated in 13.7 g fine particle with the concentration of 1506 ppm but it can be improved by adjusting the operating condition. Attrition scrubber (Fagergren

China GCX Attrition Scrubber Manufacturers and Suppliers

GCX attrition scrubber is a scrubbing equipment that needs no medium, which mainly consists of reducer driving system, polygonal tank and turbine blades agitator. For scrubbing and polishing minerals without grinding media. Inclined straight and even number blades, and adjacent ones with opposite inclination angles.