crushers primary secondary and tertiary crushers-Primary Secondary And Tertiary Crushers

Crushers and Their Types IspatGuru

2015年4月3日Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher

Types of Crushers: What You Need to Know Machinery Partner

The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits. Primary crushing involves using a large object as the initial

What Is Primary, Secondary, and Tertiary Crushing? Eagle Crusher

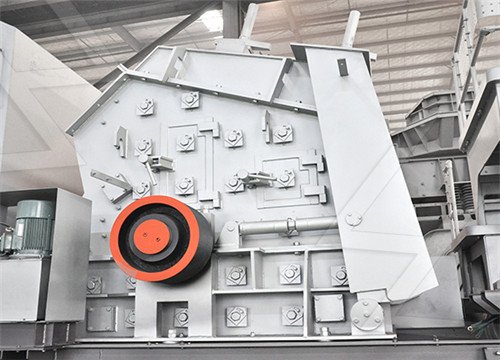

2021年1月10日Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone

Primary Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. Abstract. Detail descriptions of designs are given of large gyratory

11.19.2 Crushed Stone Processing and Pulverized Mineral

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the

Downstream Crushing Options for Secondary, Tertiary and

2021年4月12日Secondary crushing (or intermediate crushing) accepts the material from the primary crushing stage and reduces it even further, whether for final product sizing

Different types of crushing equipments Constro Facilitator

2020年5月6日There are three types of crushers. Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The

Crushing in Mineral Processing Eastman Rock Crusher

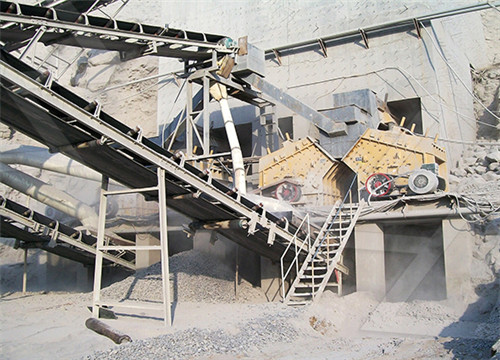

2020年4月20日The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a

SecondaryTertiary Crushing Circuits Mineral Processing

2015年7月24日Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and tertiary crushing circuit there are

Cone Crusher an overview ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers.

Types of Crushers: What You Need to Know Machinery Partner

The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits. Primary crushing involves using a large object as the initial force to break down very large and hard rocks and boulders into smaller pieces before they move onto the secondary stage.

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Primary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The primary crushing stage at the top of the machine and the secondary stage at the bottom of the machine both consist of a double-roll arrangement. Due to the feed opening and design of the top stage,

Crushing in Mineral Processing Eastman Rock

2020年4月20日The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen

What is Primary, Secondary and Tertiary Crushing? Polygonmach

2022年11月5日Crushing and screening plants manufactured by Polygonmach offer a wide range of mobile crushing and screening plants, both closed circuit and open circuit, producing powerful crushers such as primary, secondary and tertiary crushers, horizontal shaft crushers, jaw crushers and cone crushers.

What is Primary, Secondary and Tertiary Crushing?

2022年6月27日Crushing and screening plants manufactured by Polygonmach offer a wide range of mobile crushing and screening plants, both closed circuit and open circuit, producing powerful crushers such as...

CRUSHERS Mekaglobal

CRUSHERS Reliable primary, secondary and tertiary crushing groups that have been designed and manufactured with precise engineering and first-class workmanship. Our crushers have been designed to fullfill the various requirements of stone quarries, mining facilities and industrial crushing groups—primary, secondary and tertiary—which are

Secondary Crushing Equipment Mineral ProcessingMetallurgy

2016年2月28日The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its feed.

Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher

Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher Machine,Primary Limestone Concrete Gravel Jaw Crusher,Find Complete Details about Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher Machine,Primary Limestone Concrete Gravel Jaw Crusher,Large Output Mine Stone

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日These crushers can be used as either secondary or tertiary crushers depending on the application. When interlinked to other mobile units such as a primary or screen, complicated technical processing can be achieved. Mobile cone crushers have been on the market for many years. These machines can be specially designed for

Cone Crusher an overview ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers.

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

CRUSHERS Mekaglobal

CRUSHERS Reliable primary, secondary and tertiary crushing groups that have been designed and manufactured with precise engineering and first-class workmanship. Our crushers have been designed to fullfill the various requirements of stone quarries, mining facilities and industrial crushing groups—primary, secondary and tertiary—which are

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The primary crushing stage at the top of the machine and the secondary stage at the bottom of the machine both consist of a double-roll arrangement. Due to the feed opening and design of the top stage,

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日Although their common and basic function is reducing large size of rock into small size, they are applied to different crushing stages like primary, secondary, tertiary, quaternary stages. It is necessary to clarify what are the differences between all crusher types because any of them can maximize their value only in an optimal

Crushing in Mineral Processing Eastman Rock

2020年4月20日The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen

The role of jaw crusher in primary crushing

2020年7月4日Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on...

Impact crusher TTC-5-1212 TTC Mühendislik stationary / fine

Tertiary impact crushers are designed for crushing soft and medium hard materials into neat cubic shapes. These crushers are the perfect solution to obtain fine aggregates that are highly suitable for asphalt and concrete production. POWDER MACHINE Tertiary impact crusher should be used especial...

Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher

Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher Machine,Primary Limestone Concrete Gravel Jaw Crusher,Find Complete Details about Mining Iron Ore Crushing Machine,Quarry Aggregate Granite Jaw Crusher Machine,Primary Limestone Concrete Gravel Jaw Crusher,Large Output Mine Stone

Two vs three-stage crushing Australian Mining

The ideal crushing ratios for rolls crushers in coal are Primary <4:1 Secondary <2.5:1 Tertiary <3:1 More recently, larger diameter tertiary and secondary DDC-Sizers have been developed with a more robust tooth profile. These machines are suitable for the ever-increasing tonnages required by mining companies.

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日Cone crushers are used in secondary, tertiary and quaternary stages. With proper choke-feed, cone-speed and reduction-ratio settings, cone crushers will efficiently produce material that is high quality and cubical in nature. In secondary stages, a standard-head cone is usually specified.

Buyer's Guide: Crushers EquipmentContracting

Impact Crushers. An impact crusher (also called a hammer crusher) is quite versatile. It can be used as a primary, secondary, or tertiary crusher. Impact plates and beaters or hammers are used to break down the material. The material is fed through the upper part of the crusher then hit by hammers. Next, the pieces are thrown toward the

What is a Jaw Crusher? MEKA Crushing Equipment

Secondary Crushing This is the second stage of crushing. Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm. Tertiary Crushing This is the third stage of crushing.