industrial application of jaw crushers

Jaw Crushers McLanahan

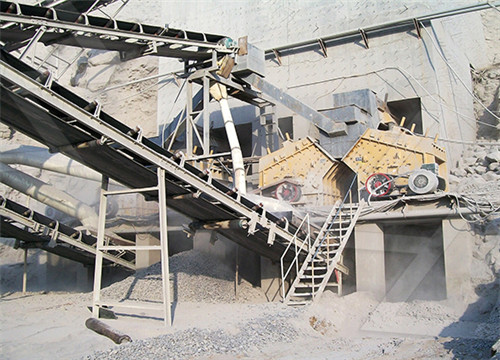

The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry. How Jaw

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and

Jaw Crushers Astec

Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology for processing applications, including aggregates, mining and recycling in

® C Series™ jaw crushers Metso Outotec

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw

applications of jaw crusher

2023年2月20日Industrial processing: Jaw crushers can be used in various industrial processes, such as cement manufacturing, where they are used to crush raw materials

Jaw crusher: types, principle and applications ResearchGate

Jaw Crusher can be used in mining, metallurgical industry, construction, road and railway building, chemistry etc. FEATURES OF JAW CRUSHER • Simple structure easy

The application of jaw crusher in different industry

The application of jaw crusher in different industry Our crusher machine has many different kinds and the application is also widely. Jaw crusher is widely used in mining,

IndustriesApplications Eagle Crusher

Recycled concrete, asphalt, aggregate, sand and gravel, or whatever your application–Eagle Crusher UltraMax® impactors, jaw crushers, and cone crushers

Jaw crusher types and applications News of Joyal Crusher

2021年6月24日Due to its simple structure, easy manufacturing, reliable work, and convenient maintenance, jaw crushers are widely used in metallurgy, mining, building

Jaw Crushers high quality and reliability from RETSCH

A jaw crusher is used for coarse and preliminary size reduction on a laboratory scale of medium-hard, hard, tough and brittle materials. This is often followed by further pulverization of the sample to analytical fineness in a laboratory mill. Typical materials include coal, ores, minerals, ceramics or building materials.

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur,

Jaw Crushers Retsch @dkshgroup

Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Applications. Alloys, basalt, cement clinker, ceramics, chamotte, coal, coke

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Concrete aggregates properties crushed by jaw and

2019年1月1日The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

applications of jaw crusher

2023年2月20日Industrial processing: Jaw crushers can be used in various industrial processes, such as cement manufacturing, where they are used to crush raw materials before they are ground into a fine...

A fundamental model of an industrial-scale jaw crusher

In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

Jaw crusher types and applications News of Joyal Crusher

2021年6月24日In terms of medium and fine crushing, jaw crushers are mostly selected for small output. Otherwise, choose a cone crusher. Feeding mouth width greater than 600mm is a large-scale crusher, feeding mouth width 500-600mm is a medium-sized crusher, and feeding mouth width is less than 500mm is a small crusher. The jaw

Monde High Efficiency Crushing Bucket Excavator Rock Jaw Crusher

Crusher Bucket is usually installed on the excavator, using the hydraulic power of the excavator, relying on the strong pinch of the upper and lower jaws to crush the stone, which can crush the stone and construction waste, and can quickly separate the steel bars in the concrete, which can reduce the handling of concrete blocks on the project site.

Product datasheet Eccentric R oll Crusher ERC® 25-34

concept, combining a crusher and a screen, the ERC 25-34 has a compact design that simplifies transportation, installation and maintenance. Flexible machine setting The crushing jaw of the ERC 25-34 features a patented fully hydraulic gap setting/retraction system with a wide gap setting range. This allows safe and simple adjustment of product

Jaw crusher: types, principle and applications ResearchGate

Blake jaw crusher: In the Blake or jaw crusher the moveable jaw is pivoted at top. The greatest amount of motion is at the bottom which means it has the little tendency to choke. Dodge jaw crusher

5 Limestone crushers make benefits to limestone plant-mpl Industrial

2023年3月3日As one of the key products of mpl, various types of jaw crushers are mainly used in the front crushing process of limestone crushing production line, which can be used individually or together with other crushing products. Feeding size: 0-1200mm. Discharge size: 20-300mm. Capacity: max to 1510t/h. Advantages of limestone jaw

Jaw Crusher Manufacturers Suppliers IQS Directory

Jaw crushers are important parts in a wide variety of industrial processes. Just a few of these processes include: Rock Crushing in Mining Operations Trash Compacting in Waste Management and Recycling Facilities Materials Management and Disposal During Construction or Demolition Projects Industrial Processing Using Jaw Crushers

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing.

Jaw Crushers high quality and reliability from RETSCH

A jaw crusher is used for coarse and preliminary size reduction on a laboratory scale of medium-hard, hard, tough and brittle materials. This is often followed by further pulverization of the sample to analytical fineness in a laboratory mill. Typical materials include coal, ores, minerals, ceramics or building materials.

Jaw Crushers Retsch @dkshgroup

Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Applications

Concrete aggregates properties crushed by jaw and

2019年1月1日The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Jaw crusher: types, principle and applications ResearchGate

Blake jaw crusher: In the Blake or jaw crusher the moveable jaw is pivoted at top. The greatest amount of motion is at the bottom which means it has the little tendency to choke. Dodge jaw crusher

A fundamental model of an industrial-scale jaw crusher

In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

Why is manganese jaw used in a crusher?

2023年3月2日Manganese jaw crushers are used in the crushing of mined ore, on industrial sites and in waste management facilities. The jaws are designed to crush and grind materials quickly and efficiently

Jaw crusher types and applications News of Joyal Crusher

2021年6月24日In terms of medium and fine crushing, jaw crushers are mostly selected for small output. Otherwise, choose a cone crusher. Feeding mouth width greater than 600mm is a large-scale crusher, feeding mouth width 500-600mm is a medium-sized crusher, and feeding mouth width is less than 500mm is a small crusher. The jaw

Monde High Efficiency Crushing Bucket Excavator Rock Jaw Crusher

Crusher Bucket is usually installed on the excavator, using the hydraulic power of the excavator, relying on the strong pinch of the upper and lower jaws to crush the stone, which can crush the stone and construction waste, and can quickly separate the steel bars in the concrete, which can reduce the handling of concrete blocks on the project site.

Product datasheet Eccentric R oll Crusher ERC® 25-34

concept, combining a crusher and a screen, the ERC 25-34 has a compact design that simplifies transportation, installation and maintenance. Flexible machine setting The crushing jaw of the ERC 25-34 features a patented fully hydraulic gap setting/retraction system with a wide gap setting range. This allows safe and simple adjustment of product

5 Limestone crushers make benefits to limestone plant-mpl Industrial

2023年3月3日As one of the key products of mpl, various types of jaw crushers are mainly used in the front crushing process of limestone crushing production line, which can be used individually or together with other crushing products. Feeding size: 0-1200mm. Discharge size: 20-300mm. Capacity: max to 1510t/h. Advantages of limestone jaw

Jaw Crusher an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

mpl Jaw crushers All the products on DirectIndustry

THYSSENKRUPP INDUSTRIAL SOLUTIONS (FRANCE) (1) Tinius Olsen (1) TTC Mühendislik (7) U; Mobile Crusher Wide applications, mpl Mobile Primary Jaw Crusher KE750-1 is a mobile crushing equipment for coarse crushing. The whole machine includes four systems: feeding, screening, conveying and crushing.