vibrating screens for slip and spray dried powder-vibrating screen drying

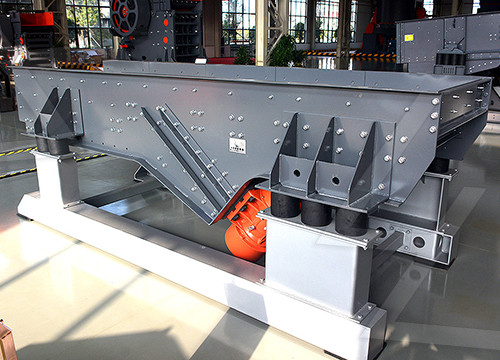

Vibratory Screens General Kinematics

Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From

Syntron Material Handling Vibrating Screens

These four ruggedly constructed vibrating screen models provide medium and heavy-duty service screening for a wide range of materials in the coal, aggregate, asphalt, pulp and , and chemical handling industries.

Screen Media Vibrating Screen Best Vibrating Screen

Screen Media. Vibrating Screens deliver unmatched precision performance dependable production even under adverse operating conditions, or when handling the most abrasive material types. Rubber

Vibratory Screening and Dewatering Tinsley Equipment Company

They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular

Vibrating screeners from Witte gently separate granular products

Witte Features: 10, 23, 35, 47 inch standard widths. Dust-tight covers featuring the Witte Clamp. Sanitary, stainless steel designs with continuously welded seams available to

Vibrating Screens Kinergy

Kinergy Driven Vibrating Screens. A “Dust-Tight” Screening Feeder to a Secondary Crusher. It is 11 ft. (3.2 m) wide, 40 ft. (12.2 m) long and 48″ (1.2 m) deep. Rated 2000 TPH of Limestone that screens the less than 6″

Vibrating Screens Recycling Systems

Vibrating Screens Recycling Systems VIBRATING SCREENS Our heavy duty screens are configurable to give 2-4 output fractions, with various screening media

vibrating screens for slip and spray dried powder

honert vibrating screens chattisgarh ataFinch. vibrating screenfor slip body. Vibrating screens, iron removers, accessories . Body and glaze preparation; Shaping; Additional

vibrating screens for slip and spray dried powder

Vibrating screens, iron removal systems and accessories. Machines and accessories for treatment of slip, glaze and spray-dried powder for tableware production. Info request.

Vibratory Screeners, Sifters,Separators Kason Corporation

We offer gravity-fed and in-line pneumatic models with single or multiple screening decks, one imbalanced-weight or two imbalanced-weight gyratory motors, and a wide range of diameters from 18 in (460mm) to 100 in (2540 mm). Some of our typical configurations include: Standard single- and multi-deck quick-ship screeners.

Vibrating screens SKF

SKF solutions for vibrating screens help you face these equipment demands to obtain reliable uptime and cost-effective maintenance. Increase service life for more reliable, cost-effective production. Vibrating screen equipment in mineral processing has a tough job. The eccentric motion with high vibration coupled with heavy loads puts a strain

Screen Media Vibrating Screen Best Vibrating Screen ASGCO

Screen Media. Vibrating Screens deliver unmatched precision performance dependable production even under adverse operating conditions, or when handling the most abrasive material types. Rubber screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone, Coal And much more. URETHANE SCREENS. Rubber

Inclined Screens McLanahan

MAX Series Vibrating Screens are available in a range of sizes from 6’ x 16’ (1.8m x 4.8m) to 8’ x 24’ (2.4m x 7.3m). They are designed to fit into any existing structure and operation with no rework. Backed by McLanahan’s years of industry experience, we work with each customer to make sure their MAX Series Vibrating Screen meets the

Screening, Separation and Vibration Mining Technology

Available screening, separation and vibration equipment and services for mining include: Vibrating conveyors, including trough conveyors, hopper discharge units, guided arm troughs and spiral conveyors. Advanced separation solutions using X-ray fluorescence technique and high-resolution RGB camera.

Choosing the Proper Vibratory Screener powderbulksolids

2018年1月3日A vibratory screener is a piece of equipment used to separate materials by particle size, remove small amounts of oversized materials from fine material, or remove excess liquid from finished products. Screeners are used in industries as diverse as , pharmaceutical, chemical, coal, minerals, pelleting, asphalt, and many more.

Vibrating Screens Kinergy

Kinergy Driven Vibrating Screens. A “Dust-Tight” Screening Feeder to a Secondary Crusher. It is 11 ft. (3.2 m) wide, 40 ft. (12.2 m) long and 48″ (1.2 m) deep. Rated 2000 TPH of Limestone that screens the less than 6″ rock, it consumes 45 hp (34 kW). The adaptation of the patented Kinergy Drive System to Vibrating Screens is recognized

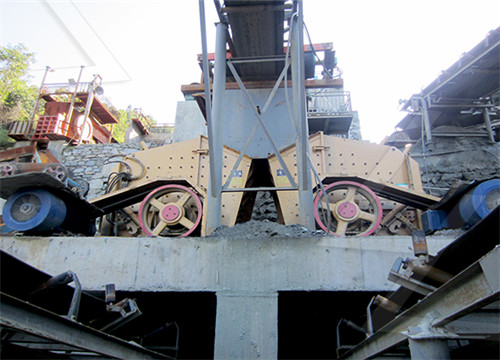

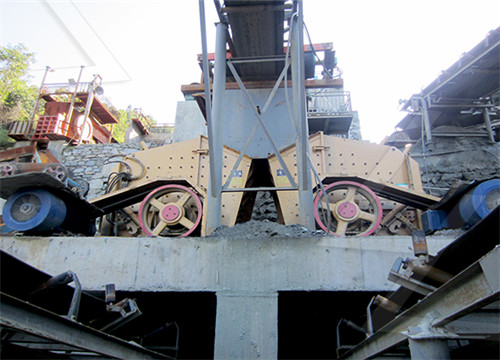

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

its vibrating mechanisms with the bearing a slip fit on the replaceable sleeve, and a press fit in the housing. The replaceable sleeve is a slip fit on the shaft. Slip fits assure more even wear on the bearings and sleeves providing longer life and easier replacement. The vibrating mechanism is demountable and readily interchangeable. Where a

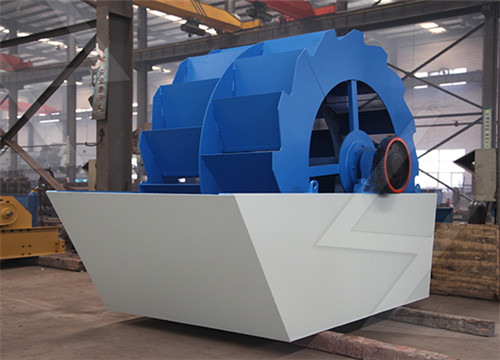

Dewatering screens remove excess moisture for faster drying

An effective alternative to filter presses and dewatering screws, the Witte vibrating dewatering screens are ideal for drying plastic pellets, ground meats, nuts and seeds, fruits and pulps, shredded and chopped recycled material and other viscous products where a very low moisture level is required at dryer discharge and cost is an important

vibrating screens for slip and spray dried powder

Powder Coating Vibrating Screeners and Industrial Sieves. As the powder coating process has become extremely common and important since its introduction in the USA over 40 years ago, representing now over 15% of the total industrial finishing market, and is used in a wide range of products; VibraScreener™ focus is to position powder coating as one of

Analysis of the dynamic forces acting on a vibrating screen and

2021年5月1日Vibrating screens are equipment used in various industries, such as mining, steel and . Although it is simple to install vibratory equipment on a support structure, it is necessary to consider the static and dynamic forces caused by vibration. Analysing the vibrating screen, graphs were made to compare the displacements,

Vibrating screen EVA rubber powder screening display YouTube

Vibrating screen EVA rubber powder screening display YouTube 0:00 / 0:20 Vibrating screen EVA rubber powder screening display 58 views Dec 6, 2021 0 Dislike Share Save Chunying...

Vibrating Screen Separators in the Pulp and Paper Industry

A. WOOD PREPARATION. 1. Hydraulic Barkers: Kason's are used to clarify and remove suspended solids from recirculated water that could cause serious damage to very high pressure (1000 psi or more) pumps used in this barking process. Screens from 24-46 mesh are employed and capacities up to 750 GPM are reported.

vibrating screens for slip and spray dried powder

vibrating screens for slip and spray dried powder. through a-vibrating screen to remove particles with sizes over 125-200 urn, It is Keeping the moisture content of the spray-dried powder virtually constant at the glazing with high density glaze slip to avoid formation of entrapped bubbles. ; What Does A Vibrating Grizzly Feeder Do

Vibratory Screeners, Sifters,Separators Kason Corporation

We offer gravity-fed and in-line pneumatic models with single or multiple screening decks, one imbalanced-weight or two imbalanced-weight gyratory motors, and a wide range of diameters from 18 in (460mm) to 100 in (2540 mm). Some of our typical configurations include: Standard single- and multi-deck quick-ship screeners.

Screening, Separation and Vibration Mining Technology

Available screening, separation and vibration equipment and services for mining include: Vibrating conveyors, including trough conveyors, hopper discharge units, guided arm troughs and spiral conveyors. Advanced separation solutions using X-ray fluorescence technique and high-resolution RGB camera.

How To Size and Select a Vibrating Screen for an Aggregate

2022年2月15日Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

Screen Media Vibrating Screen Best Vibrating Screen ASGCO

Screen Media. Vibrating Screens deliver unmatched precision performance dependable production even under adverse operating conditions, or when handling the most abrasive material types. Rubber screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone, Coal And much more. URETHANE SCREENS. Rubber

Vibrating Screens Kinergy

Kinergy Driven Vibrating Screens. A “Dust-Tight” Screening Feeder to a Secondary Crusher. It is 11 ft. (3.2 m) wide, 40 ft. (12.2 m) long and 48″ (1.2 m) deep. Rated 2000 TPH of Limestone that screens the less than 6″ rock, it consumes 45 hp (34 kW). The adaptation of the patented Kinergy Drive System to Vibrating Screens is recognized

Analysis of the dynamic forces acting on a vibrating screen and

2021年5月1日The designed equipment presented in this work is a vibrating dewatering screen, model PVD 1206 1 A (Fig. 1), with a nominal length of 1200 mm and nominal width of 600 mm, which was developed with the upper double mechanism, driven by two motors via cardans [1].Its two mechanisms at the top, with unbalanced masses, cause a

Vibratory Screening and Dewatering Tinsley Equipment Company

They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed. High capacity screening equipment can screen or classify material ranging in sizes from 1/8 inch (3mm) down to 325 mesh.

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

its vibrating mechanisms with the bearing a slip fit on the replaceable sleeve, and a press fit in the housing. The replaceable sleeve is a slip fit on the shaft. Slip fits assure more even wear on the bearings and sleeves providing longer life and easier replacement. The vibrating mechanism is demountable and readily interchangeable. Where a

VSMA Package All 4 PDF AEM

Product Description. Downloadable PDF, in black and white. Complete your vibrating screen reference library and order the entire set of vibrating screen booklets developed by AEM's Vibrating Screen Manufacturers Association (VSMA): VSMA Vibrating Screen Handbook; Vibrating Screens: Safety and Good Operating Practices; Vibrating Screens

vibrating screens for slip and spray dried powder

Powder Coating Vibrating Screeners and Industrial Sieves. As the powder coating process has become extremely common and important since its introduction in the USA over 40 years ago, representing now over 15% of the total industrial finishing market, and is used in a wide range of products; VibraScreener™ focus is to position powder coating as one of

Inclined Screens McLanahan

MAX Series Vibrating Screens are available in a range of sizes from 6’ x 16’ (1.8m x 4.8m) to 8’ x 24’ (2.4m x 7.3m). They are designed to fit into any existing structure and operation with no rework. Backed by McLanahan’s years of industry experience, we work with each customer to make sure their MAX Series Vibrating Screen meets the

Vibrating screen EVA rubber powder screening display YouTube

Vibrating screen EVA rubber powder screening display YouTube 0:00 / 0:20 Vibrating screen EVA rubber powder screening display 58 views Dec 6, 2021 0 Dislike Share Save Chunying...

Analysis of the dynamic forces acting on a vibrating screen and

2021年5月1日Vibrating screens are equipment used in various industries, such as mining, steel and . Although it is simple to install vibratory equipment on a support structure, it is necessary to consider the static and dynamic forces caused by vibration. Analysing the vibrating screen, graphs were made to compare the displacements,

Vibrating screens SKF

SKF solutions for vibrating screens help you face these equipment demands to obtain reliable uptime and cost-effective maintenance. Increase service life for more reliable, cost-effective production. Vibrating screen equipment in mineral processing has a tough job. The eccentric motion with high vibration coupled with heavy loads puts a strain