used machinery for processing iron ore

Iron Ore Processing Equipment FEECO International Inc.

Our heavy-duty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the

Sintering Process Equipment Used in Iron and Steel

Sinter is the primary feed material for making iron in a blast furnace. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control

Iron Ore Processing,Crushing,Grinding Plant Machine

Flotation is mainly used to process limonite and other kinds of iron ores Through detailed mineralogy study and lab processing test, a most

Iron Processing Equipment, Process Flow, Cases JXSC Machine

The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore. 6.2 Magnetic separation cation reverse flotation process The grade of iron

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines. Our team of experts can help you with

Iron Ore Mining Equipment Iron Ore Beneficiation CDE CDE

Our iron ore processing plants target these contaminants and ensure their effective removal from the feed to the kilns. This has the effect of increasing the Fe value of the

Open-Pit Mining Method and Process Epiroc US

2021年1月7日SmartROC D65 key to Kaunis Iron. January 7, 2021. 2021 Surface miningquarrying Mining International Surface SmartROC D65 Surface and Exploration Drilling division Customer story. Just two

Top 10 Best Mineral Processing Equipment Fote Machinery

Ftmmachinery mineral processing equipment can process non-ferrous and ferrous metals, precious metals and non-metallic ores, such as gold ore, iron ore, copper ore,

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat. Before being delivered to the sinter machine, the ore mixture is

Iron Ore Processing Equipment FEECO International

Our heavy-duty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a popular alternative

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines. Our team of experts can help you with any questions you may have about cyclones, spirals, drums and samplers, and provide support during the stages of iron ore processing. Iron Ore Flow Sheet

Common Types of Mining Equipment Used in the Mining Industry

2021年3月25日Motor graders are used for surface operations around mines to create and maintain these roads. When hauling minerals, ore, or other mined materials along roads, things like debris or ponding water can slow vehicles. Motor graders ensure the roads have the necessary grading and adequate drainage.

how to set up a iron ore processing plant

2023年3月3日Design the plant: You will need to design your processing plant to optimize the recovery of iron ore and minimize waste. This will involve selecting equipment and designing processes for crushing

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength magnetic separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Commonly used grinding equipment in the non-metallic ore

For non-metallic ore grinding, the selection of processing equipment is very important. Different types of grinding equipment are suitable for minerals with different properties, and have specific correspondence to hardness, raw material particle size, humidity, output, etc. Understanding the working principle, performance characteristics, and scope of

Iron ore crushing system (2011) Dayuan Chen 3 Citations

The utility model discloses an iron ore crushing system which comprises a coarse crusher, a middle crushing crusher, a sieve IV, a closed circuit fine crusher, a high pressure roller mill and a groove type ore washer, wherein a sieve I is arranged at the outlet of the coarse crusher; the middle crushing crusher is used for crushing plus sieve materials of the

10tph Mining Process Recovery Rutile Ore Concentrating Spiral

10tph Mining Process Recovery Rutile Ore Concentrating Spiral Chute,Find Complete Details about 10tph Mining Process Recovery Rutile Ore Concentrating Spiral Chute,Rutile Ore Concentrating Spiral Chute,Iron Ore Concentration Plant,Iron Processing Plant Machine from Supplier or Manufacturer-Jiangxi Province County Mining Machinery Factory

Metso Outotec wins order for iron ore pelletising plants

2023年3月3日Metso Outotec is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. Metso Outotec wins order for iron ore pelletising plants in China. ANALYSIS, china, commercial vehicles, Cranes, machinery, Metso Outec, NEWS,

Production voestalpine Stahl Donawitz GmbH

Almost 70 years ago, voestalpine developed the breakthrough technology Linz-Donawitz converter process, which enabled the large-scale and rapid conversion of pig iron into crude steel. This technology is still used and about 70% of the worldwide steel production is made by this technology. More than 140 years of technical experience combined

Manganese Mining and Processing: Everything you Need to Know

Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron ore-based steel made it even harder. In today’s world, manganese is often used for cathodic shielding in the battery industry. The Basics of Manganese Mining and Processing

Metals Free Full-Text Research on Sinter Quality Prediction

Sinter ore quality directly affects the stability of blast furnace production. In terms of both physical and chemical properties, the main indicators of sinter quality are the TFe content, alkalinity, and drum index. By analyzing the massive historical data on the sinter production of a steel company, this study proposes a sinter quality prediction system based on

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat. Before being delivered to the sinter machine, the ore mixture is

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines. Our team of experts can help you with any questions you may have about cyclones, spirals, drums and samplers, and provide support during the stages of iron ore processing. Iron Ore Flow Sheet

Production voestalpine Stahl Donawitz GmbH

Almost 70 years ago, voestalpine developed the breakthrough technology Linz-Donawitz converter process, which enabled the large-scale and rapid conversion of pig iron into crude steel. This technology is still used and

Open-Pit Mining Method and Process Epiroc US

2021年1月7日Blasthole drilling is an integral part of the production process, and needs large, heavy drill rigs that can produce high meterage of often large diameter holes. These are then charged with bulk

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength magnetic separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

what is iron ore screening equipment?

2023年2月10日Iron ore screening equipment refers to the machines used to separate granulated ore material into different sizes for further processing or for end use. The screening process is an essential part

Iron Ore Beneficiation Process Metallurgist

2017年4月27日The whole process of magnetic concentration as applied to the eastern Mesabi magnetites is a good illustration of the manner in which the various types of machines can be made to work together so

10tph Mining Process Recovery Rutile Ore Concentrating Spiral

10tph Mining Process Recovery Rutile Ore Concentrating Spiral Chute,Find Complete Details about 10tph Mining Process Recovery Rutile Ore Concentrating Spiral Chute,Rutile Ore Concentrating Spiral Chute,Iron Ore Concentration Plant,Iron Processing Plant Machine from Supplier or Manufacturer-Jiangxi Province County Mining Machinery Factory

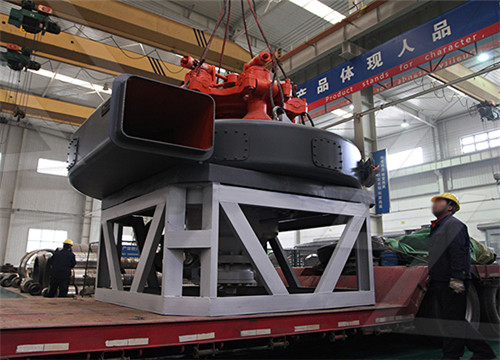

Iron ore crushing system (2011) Dayuan Chen 3 Citations

The utility model discloses an iron ore crushing system which comprises a coarse crusher, a middle crushing crusher, a sieve IV, a closed circuit fine crusher, a high pressure roller mill and a groove type ore washer, wherein a sieve I is arranged at the outlet of the coarse crusher; the middle crushing crusher is used for crushing plus sieve materials of the

Commonly used grinding equipment in the non-metallic ore

For non-metallic ore grinding, the selection of processing equipment is very important. Different types of grinding equipment are suitable for minerals with different properties, and have specific correspondence to hardness, raw material particle size, humidity, output, etc. Understanding the working principle, performance characteristics, and scope of

Manganese Mining and Processing: Everything you

Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron ore-based steel made it even harder. In today’s world, manganese is often used for

Metso Outotec wins order for iron ore pelletising plants

2023年3月3日Metso Outotec is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. Metso Outotec wins order for iron ore pelletising plants in China. ANALYSIS, china, commercial vehicles, Cranes, machinery, Metso Outec, NEWS,

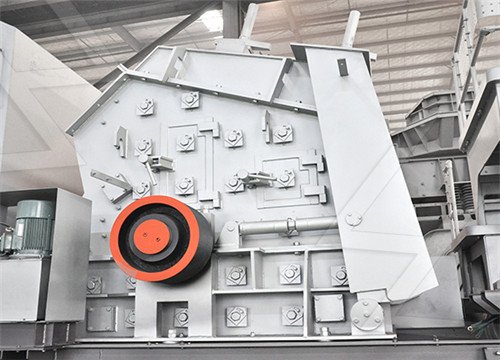

Iron Processing Equipment, Process Flow, Cases JXSC Machine

The main iron ore mining equipment includes jaw crushers, ball mills, magnetic separators, spiral classifiers, jig concentrators and related auxiliary equipment such as ore dryers. Jaw crusher reduces the hard iron ore into a smaller size, it has a high iron crushing ratio, feeding and crushing capacity, uniform texture, good grain shape.

7 Methods and Equipment for Removing Iron from Quartz Sand

2023年2月15日The following introduces 7 methods and equipment for removing iron from quartz sand. Quartz sand 1. Gravity separation method Gravity separation can usually be used effectively for the entire particle size range of quartz sand.