impact crusher planting

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure

Primary Impact Crushers MEKA Crushing

MEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration. This helps the crusher to operate safely and boosts

Impact Crushers Parker Plant

2023年3月2日 Available in three sizes, the well proven original Parker ‘Kubitizer’ Impact breaker produces material with outputs ranging from 40-200 tonnes per hour and is ideal for working in a composite crushing

(PDF) A performance model for impact crushers

2002年10月1日 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed

Impact Crusher Impact Rock Crusher AGICO

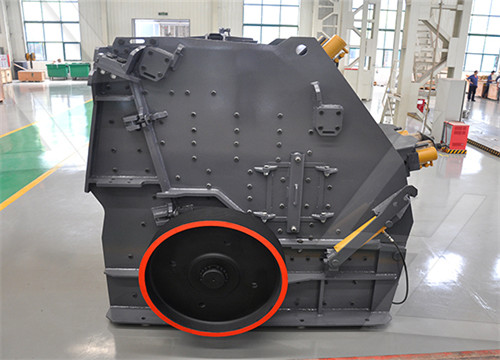

What Is Impact Crusher. Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

Impact crushers HUNING Anlagenbau

Impact crusher HPZ 900. The impact shredder HPZ 900 is used to shred organic waste and wear-intensive substrates with a high mineral content. Depending on the overall process, it can be operated both batchwise and

What is the difference between hammer crusher and

2022年2月19日 The advantage of hammer crusher. (1) The crushing ratio is large, the structure is simple, the maintenance is convenient, the product grain shape is good, and

Impact crusher structure, working principle and

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively

Impact Crushers Parker Plant

2023年3月2日 Available in three sizes, the well proven original Parker ‘Kubitizer’ Impact breaker produces material with outputs ranging from 40-200 tonnes per hour and is ideal for working in a composite crushing

Impact crushers and impact mills with a

Impact crusherimpact mill. Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and

Impact Crusher Impact Rock Crusher AGICO

What Is Impact Crusher. Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreas-style impactors. At present, we offer the New Holland-style primary impact breaker and the MaxCap X

Working Principle of 4 Commonly Used Crushers

2022年1月14日 Impact crusher can crush coarse, medium and fine mineral or rock (granite, limestone, concrete, etc.) with a particle size of less than 120-500 mm and a compressive strength of less than 320 MPa. It is widely used in hydropower, high-speed Highway, artificial sand and gravel crushing industries. The impact crusher has a unique

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

2011年5月10日 The Impact Crusher Machine rotor revolves in fixed direction by means of driving action of triangle belt that connects with motor. Above rotor, there are sets of suspended impact plates. quickly growing tensile stress may help the particles to break from within. [1] Fig.3 Scheme of breaking process in crusher [1]

Impact crusher structure, working principle and

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively

Jaw Crusher VS Impact Crusher (A Comparison

2020年2月28日 1. Application. 1. Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt. 2. Impact crusher is usually used as a medium-fine hardness crusher, such as

Primary Impact Crushers MEKA Crushing

MEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration. This helps the crusher to operate safely and boosts

Impact Crushers Parker Plant

2023年3月2日 Available in three sizes, the well proven original Parker ‘Kubitizer’ Impact breaker produces material with outputs ranging from 40-200 tonnes per hour and is ideal for working in a composite crushing

Impact Crusher Impact Rock Crusher AGICO

What Is Impact Crusher. Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm

PRIMARY IMPACT CRUSHER HPI

The HPI Crusher has two impact aprons and can also be equipped with a grinding path. The rotor is capable of handling feed material up to 3m³ and the grinding path restricts the amount of oversize product. The gap settings of the impact aprons and grinding path can be adjusted by means of spindles, or controlled hydraulically, and allow

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreas-style impactors. At present, we offer the New Holland-style primary impact breaker and the MaxCap X

Sand production crusher, Sand production crushing plant

VSI crusher RSMX series. stationary sand production. Capacity: 30 t/h 500 t/h. Motor power: 160 kW 400 kW. Weight: 7,500 kg 20,200 kg. The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials.

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日 The vertical shaft impact crusher (or VSI) has a rotating shaft that runs vertically through the crushing chamber. In a standard configuration, the VSI’s shaft is outfitted with wear-resistant shoes that catch and throw the feed stone against anvils that line the outside of the crushing chamber.

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

What Is an Impact Crusher and What Can It Do for You?

2021年1月10日 An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size. Used in a wide variety of applications, including aggregate crushing,

Impact Crushers: HorizontalVertical Shaft Ritchie List

2015 Screen Machine JXT50 Jaw Crusher Impact Crusher. Ruckersville, Virginia-$239,500 USD. Listings by GF Equip Sales. Pioneer 30X42 Impact Crusher. Saint Paul, Minnesota-On Request. Listings by Suburban Equipment Inc. 2005 Lippman 5165LS Impact Crusher. Dallas, Texas. 300 hrs. $200,000 USD.