process process of manganese ore benefication plant

A Review of Low Grade Manganese Ore Upgradation

2019年7月29日 In the present review , an attempt has been made to summarize the various kinds of beneficiation practices used to upgrade the low-grade manganese ores. A detailed analysis of Mn ore types, genesis processes, mineralogical characteristics, and

Manganese Ore Beneficiation Manganese Ore

2019年4月3日 The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the low-grade ore, improve the ore grade, reduce the energy and reagent consumption of

The 7 Most Useful Manganese Ore Beneficiation Methods

2023年2月15日 For some refractory manganese ore, it is necessary to combine two or more beneficiation methods. After studying the beneficiation process of manganese ore,

Manganese Ore Processing Mineral Processing

2016年4月27日 Units with 3 compartments were chosen to give ample capacity to produce a high-grade manganese product. Tailings from

Manganese Ore Process Plant JXSC Mineral

Manganese (Mn) is the twelfth most abundant element in the Earth’s crust. Amongst some 300 minerals containing manganese, only about a dozen are of economic significance.

Manganese Ore Beneficiation Processing Line

2020年7月27日 For manganese ore, the beneficiation methods cover gravity separation, magnetic separation and floatation separation, and the flow sheets for manganese mineral can not be only single flow sheet of

Manganese Ore Beneficiation Plant With 4

2023年3月1日 3. Brazil 200 TPH rock manganese ore beneficiation plant Brazil's manganese ore plant mainly processes the rock-type manganese ore. The manganese concentrate is about 46% and contains slime. The

Flowsheet of Manganese Ore Beneficiation Process Plant

2016年3月11日 Complete Process Plants; ConsultingEngineering. EnvironmentalSocial; Project Construction; Project ValuationOptimization; Mineral Processing;

10 Best Ore Beneficiation Plants for Sale (with Costs)

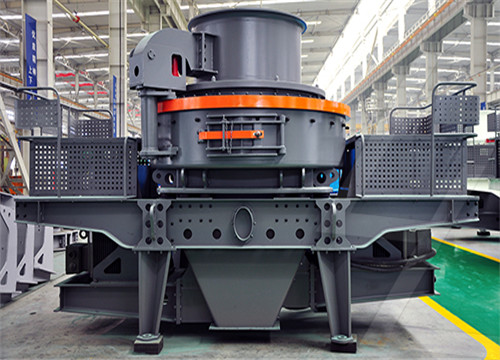

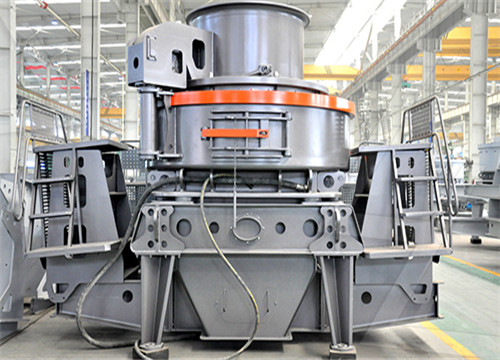

2021年3月24日 38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10

Lead Zinc Mining SolutionEquipment Mineral Processing

Generally, lead zinc flotation processing plant main process divided into three stages: crushing and screening grinding flotation separation- concentate and dewatering.

Phase, Microstructure and Beneficiation of Manganese Ore

In the present study, six process parameters were investigated i.e. the particle size of the ore, leaching temperature, time duration, Mn ore amount, sulphuric acid concentration and amount of sawdust. Manganese extraction of 88.93 (wt%) was achieved for a leaching time of 60 minutes at 120 °; C using 5% (v/v) H 2 SO 4 concentration for 10 g

manganese beneficiation ppt SlideShare

2016年1月14日 Introduction:- Manganese ore in the form of ferro and silicomanganese alloys are the most essential ingredients in the production of steel, both crude and stainless. Presently, India is the second largest

Flowsheet of Manganese Ore Beneficiation Process Plant

2016年3月11日 Flowsheet of Manganese Ore Beneficiation Process Plant. Previous. Next. by L D Michaud March 11, 2016 FlowsheetsFlowcharts manganese, Small Process Equipment.

sbm/sbm manganese beneficiation process equipment in

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Existing and New Processes for Beneficiation of Indian Iron

2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very fast, the focus is on the beneficiation of low-grade resources. However, most of these ores do not respond well to the conventional

Jianan Zhang 6 Publications 34 Citations Related Authors

Jianan Zhang is an academic researcher. The author has contributed to research in topic(s): SmeltingMagnetite. The author has an hindex of 3, co-authored 6 publication(s) receiving 34 citation(s).

Beneficiation Plant Definition Law Insider

The rock phosphate tailings is produced from the processing of low grade ore in the main process plant in the form of wet powder at Industrial Filtered tailings are produced for storage in the TSF.The layout of the Beneficiation Plant is shown in Figure 5. Manganese Ore Beneficiation Plant (Capacity 0.5 MTPA) by M/s Badebaba Mining and

Treatment of iron ore beneficiation plant process water by

2020年11月1日 Process water collected from the iron ore beneficiation plant was treated by electrocoagulation (EC) process to make it suitable for reuse or safe for discharge. Experimental studies were carried

Iron Manganese Ore Processing Equipment Clirikchina

15 小时之 How to process iron manganese ore? The processing of iron manganese ore involves several steps to separate the two minerals and produce a concentrated product that can be used in various industrial applications. Here is a general overview of the typical process: 1. Crushing: The ore is first crushed into small pieces using crushers. This helps

extraction of iron, process of iron, iron

3.This iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~-0.074 mm) going to froth flotation cells for recovery of iron. 4.In magnetite

Beneficiation and agglomeration of manganese ore fines

The difference in cost of 48%Mn ore Lumps48%Mn sintered concentrate = 11000-10325 = Rs.675/T. The main purpose of this stone is to show that establishment of beneficiation unitSintering unit is economically feasible. There are many misconcepts, still prevailing, about use of Mn ore sinters.

Manganese processing Britannica

manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an

Phase, Microstructure and Beneficiation of Manganese Ore

In the present study, six process parameters were investigated i.e. the particle size of the ore, leaching temperature, time duration, Mn ore amount, sulphuric acid concentration and amount of sawdust. Manganese extraction of 88.93 (wt%) was achieved for a leaching time of 60 minutes at 120 °; C using 5% (v/v) H 2 SO 4 concentration for 10 g

Beneficiation Plants and Pelletizing Plants for Utilizing

2015年1月27日 - Concentrate: Concentrate is ore upgraded by a beneficiation process. Sintered ore: Sintered ore is ore agglomerated by a sintering plant. Pellet: Pellet is ore agglomerated by a pelletizing plant. 1.2 Outline of iron ore production The production of iron and steel in China has increased dramatically. In response to the increasing

What Is Mineral Beneficiation? Sepro Labs

Scrubber testing pilot plant tests of scrubbers used to deagglomerate clays and other materials; Benefits of mineral beneficiation testing. Junior mining companies looking for cost-effective mineral testing services need accurate results to make informed decisions. Mineral beneficiation plays a significant role in the following lab services:

Flowsheet of Manganese Ore Beneficiation Process Plant

2016年3月11日 Flowsheet of Manganese Ore Beneficiation Process Plant. Previous. Next. by L D Michaud March 11, 2016 FlowsheetsFlowcharts manganese, Small Process Equipment.

Comminution Multotec

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into

Beneficiation Plant Definition Law Insider

The rock phosphate tailings is produced from the processing of low grade ore in the main process plant in the form of wet powder at Industrial Filtered tailings are produced for storage in the TSF.The layout of the Beneficiation Plant is shown in Figure 5. Manganese Ore Beneficiation Plant (Capacity 0.5 MTPA) by M/s Badebaba Mining and

ore beneficiation line,ore beneficiaiton plant,ore

2022年8月30日 Ore beneficiation line consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor. Email: info@sinoftm Tel:0086-371-

More high-grade iron-ore needed to accelerate steel

2022年7月13日 German steelmaker thyssenkrupp is planning to begin replacing its blast furnaces with DRI plants that include an integrated melting unit (submerged arc furnace) from 2025. The resultant liquid