layout of crusher and screen plant

Layout of a four-stage crushing plant for ballast

Download scientific diagram Layout of a four-stage crushing plant for ballast production. (Evertsson 2000), crusher empirical model (Whiten 1972), screen model (Karra 1979;Soldinger 2002

CrushingScreening Plant Design Factors Mineral

2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet

Setting up of crushing plant: design and layout

2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

Crushing Plant FlowsheetDesign-Layout Mineral

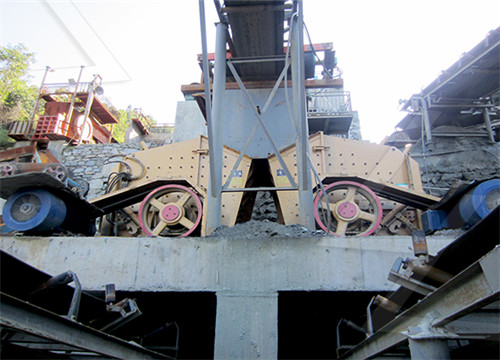

Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement. The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant a在911metallurgist上查看更多信息预计阅读时间:13 分钟

Mobile Crushing Plant And Screening Plant

Mobile Cone Crusher Plants. Maxium Feed particle size: 160-215mm Production capacity: 50-420 t/h Application field: Mining, coal, waste, and the recycling of construction waste, urban infrastructure, roads or

Crushing Plant Design and Layout

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1)

layout of crusher and screen plant

Crushing Plant FlowsheetDesign-Layout. Crushing Plant FlowsheetDesign-Layout View Larger Image In the crushing section, the ore as it comes from the mine is broken

layout of crusher and screen plant pdf

2020-3-28 In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and

Layout Of Crusher And Screen Plant Godspeedracing

2021年9月13日 The Plant features a 3055 Jaw Crusher, 57 x 20' VGF feeder with 6' of grizzly bars, FlSmidth Raptor 400 Cone Crusher, 8 x 20 TD Vibrating Screen and a Self

Layout Of Crusher And Screen Plant Julypilates.de

2022年2月22日 Crushing Amp Screening Plants Parker Plant. The crushranger models available are two stage, closedcircuit arrangements with jaw, cone, rolls crusher and

Layout of a four-stage crushing plant for ballast

Download scientific diagram Layout of a four-stage crushing plant for ballast production. (Evertsson 2000), crusher empirical model (Whiten 1972), screen model (Karra 1979;Soldinger 2002

How to Design a Crushing Plant Imagup

2020年12月2日 In general, the effective volume of the hopper design should meet the following two conditions at the same time. No less than the workload of continuous operation of the crusher for 12-15 minutes. The carrying capacity of no less than 3 transport vehicles. 2. The layout of the crushing workshop.

Tips for designing an efficient crushing and

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

Crushing and Screening Agg-Net

2 之 Listed in. By L. Winchip, engineering manager, and G. Mangrich, regional sales manager, McLanahan Corp. Several considerations need to be taken into account in designing an efficient crushing and screening plant, the first being the raw materials to be crushed. The quarry shot material should be analyzed for maximum feed size, gradation

Stone Crushing Plant Automatic Stone Crusher Plant

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment. The designed output is generally 30-350 tons per hour. According to different technological requirements, we can also equip the dust

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

HSE Quarries Safe operation and use of mobile jaw

2022年11月23日 Written instructions should be issued to plant operators. This should detail the procedures to follow in the event of a crusher stalling. These instructions should include the following: Isolation of motive power to the crusher and associated plant procedure in operation at the site ; Clear the area of all personnel

layout of crusher and screen plant

Crushing Plant FlowsheetDesign-Layout. Crushing Plant FlowsheetDesign-Layout View Larger Image In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if . get price

Layout Of Crusher And Screen Plant Julypilates.de

2022年2月22日 Crushing Amp Screening Plants Parker Plant. The crushranger models available are two stage, closedcircuit arrangements with jaw, cone, rolls crusher and screen options mounted on one chassis. recycling plants the parker rm and rj models are ideal for recycling, demolition and volume reduction applications in constrained inner city, urban

Tips for designing an efficient crushing and

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

Crushing and Screening Agg-Net

2 之 Listed in. By L. Winchip, engineering manager, and G. Mangrich, regional sales manager, McLanahan Corp. Several considerations need to be taken into account in designing an efficient crushing and screening plant, the first being the raw materials to be crushed. The quarry shot material should be analyzed for maximum feed size, gradation

ROCK CRUSHING PLANT APPLICATIONS ADVICE

2020年3月28日 In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles. It may also involve portable generators powered by diesel engines. Emissions of each pollutant must be less than 100 TPY for the facility to be a minor source.

Mineral Processing Crushing Plant design,

PRIMARY CRUSHER SELECTION CRITERIA • Will it produce the desired product size at required capacity • Will it accept the largest feed size expected • What is the capacity to handle peak loads • Will it choke or

(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

The grade of concrete considered for this study purpose is M20. It is found that as the age of aggregate crusher screen increases from 0-2 years, 2-4 years, 4-6 years and more than 6 years the fineness modulus increases it shows that older the crusher screen, the average particle size of coarse aggregates increases.

HSE Quarries Safe operation and use of mobile jaw

2022年11月23日 Written instructions should be issued to plant operators. This should detail the procedures to follow in the event of a crusher stalling. These instructions should include the following: Isolation of motive power to the crusher and associated plant procedure in operation at the site ; Clear the area of all personnel

design a crusher plant Crushing and Screening Plant

Stone Crusher Tanjung Duren,50th Crusher Plant Design and stone quarry plants Time ,50th Crusher Plant Design and design for crushing plant Grinding Mill China 4.6/5 4.9K ratings Crusher Wikipedia, the free encyclopedia.

Layout Of Crusher And Screen Plant Godspeedracing

2021年9月13日 The Plant features a 3055 Jaw Crusher, 57 x 20' VGF feeder with 6' of grizzly bars, FlSmidth Raptor 400 Cone Crusher, 8 x 20 TD Vibrating Screen and a Self Cleaning Magnet. is the world's leading manufacturer of crushers, screeners, and conveyors for the aggregates, recycling, and mining industries.

Layout Of Crusher And Screen Plant Julypilates.de

2022年2月22日 Crushing Amp Screening Plants Parker Plant. The crushranger models available are two stage, closedcircuit arrangements with jaw, cone, rolls crusher and screen options mounted on one chassis. recycling plants the parker rm and rj models are ideal for recycling, demolition and volume reduction applications in constrained inner city, urban