type of crusher in india list

Crushing MachinesPlants at Best Price in

Aesha Conveyors And Crushing Equipment. Contact Supplier. Amey Engineers Paper Fine Crusher, Shredding Capacity: 1-500 kg/hr, Model Name/Number: Ns 300. ₹ 1.65 Lakh. Amey Engineers. Contact Supplier.

All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a

Crusher manufacturers in india Avishkar Industries Pvt Ltd

2020年7月10日 Crusher is a machine designed specifically for extracting and breaking processes. It is used to crush or reduce the size of giant rocks into minor rocks, and rock

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Comparison of actual crushing cases of two crusher types Cone crusher for pebble processing site in India. The classical size of pebble is 63mm-12mm. The

Mobile Crushing Plant at Best Price in India

Cone Crusher Stainless Steel Mobile Screening Plant 100tph Full ₹ 45 Lakh. Get Quote. Agarwalla Bpa Jaw Crusher 75 Tph Modular Crushing Plant, For Stone ₹ 1.05 Crore. Get Quote. Agarwalla Jaw Crusher Mobile

Types of Crushers: What You Need to Know Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on

Crushing 101 Different types of crushers for distinctive

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher.

Jaw Crusher Latest Price from Manufacturers, Suppliers

Trilok Industries. 380V 440V 75-150 Electric Jaw crusher. 25 Lakh 85 Lakh /Piece. Tech-maxx International. BSMW High Mine Steel MS industrial jaw crusher. 2.05 Lakh /Unit.

Types of Crushers Mineral Processing

2015年6月23日 Fairmount type crusher. During the same years wherein the industry was concerned with development of larger and still larger primary crushers,another member of the family was born: the single,

Github

types of crusher plant india. Crusher. A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant.Gyratory crushers are designated in size e

Jaw Crusher Latest Price from Manufacturers, Suppliers

Trilok Industries. 380V 440V 75-150 Electric Jaw crusher. 25 Lakh 85 Lakh /Piece. Tech-maxx International. BSMW High Mine Steel MS industrial jaw crusher. 2.05 Lakh /Unit. BS Mechanical Works. ISO 9001:2008 380V 1-5kw Electric 30 X15 Jaw Crusher. 8 Lakh

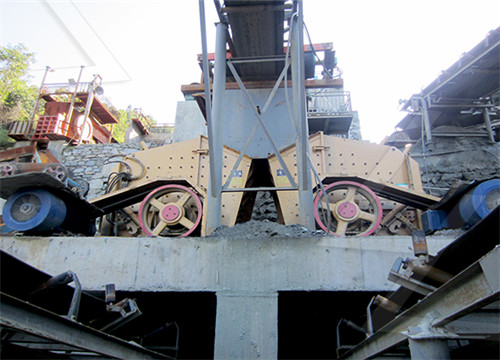

Crushing Machine Secondary Impact Crusher

12500kgs. I Deal In. New Only. Closed Side setting (CSS) Range. 18 30mm. Country of Origin. Made in India. GECO Cone crusher offers the highest crushing effeciency and end product quality with low cost per ton

Crusher Machine For Sale Types Of Crushing Machines

The advantages of jaw crusher. 1. Welding frame structure, very firm and reliable. We use a high-quality steel plate welding frame, avoid casting defects, is a more solid and reliable whole body. 2. Flywheel design The flywheel design can effectively reduce the vibration and make the machine run more smoothly. 3.

Stone Crushing Equipment Market Analysis Industry

The global stone-crushing equipment market was valued at USD 5.55 billion in 2021 and is expected to surpass a net valuation of USD 8.45 billion by 2027 end, registering a solid CAGR growth of 7.25% over the forecast period. Due to the COVID-19 pandemic, many industries, including the construction industry, witnessed a slump in investment in 2020.

Type of crushers and their difference JXSC Mining

2019年12月10日 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

What Type of Crusher Is Best for Primary

2021年3月25日 Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry to slightly wet material but not sticky material. Gyratories are

4 Types of Stone Crushers' Maintenance and

2023年2月15日 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 stockyard and the crusher is by-passed. In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used

Stone Crusher Project Report Technical Financial

There are many types of stone crushers in India. Their size and type depend on the location of the stone crusher plant and demand for the crusher products, urban or rural area or the raw material available etc. The types of stone crushers, in general, are small, medium and large-sized stone crushers. Small Sized Stone Crushers Mini Stone Crusher

Vsi Crusher TradeIndia Indian Exporters, Manufacturers,

Product Type: Stone Crusher General Use: Stone Material: Mild Steel, Other Vindhya Engineering. ImporterManufacturer of VSI crusher in Delhi, India. It includes three types of crushing and can be operated hours continuously. Now...View More. Gaurav Pharma Ltd. Delhi, India 407-408, Gopal Heights, Netaji Subhash Place, Pitam Pura,

Crushing Machine Secondary Impact Crusher

12500kgs. I Deal In. New Only. Closed Side setting (CSS) Range. 18 30mm. Country of Origin. Made in India. GECO Cone crusher offers the highest crushing effeciency and end product quality with low cost per ton

Different types of crushing equipments Constro Facilitator

2020年5月6日 Flex, Hybrid and Green to buttress India’s office market in 2023. March 3, 2023. Top News. Under PM GatiShakti, 66 big infra projects recommended for approval. March 3, 2023. Real Estate. There are three types of crushers. Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary

Type of crushers and their difference JXSC Mining

2019年12月10日 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Stone Crushing Equipment Market Analysis Industry

The global stone-crushing equipment market was valued at USD 5.55 billion in 2021 and is expected to surpass a net valuation of USD 8.45 billion by 2027 end, registering a solid CAGR growth of 7.25% over the forecast period. Due to the COVID-19 pandemic, many industries, including the construction industry, witnessed a slump in investment in 2020.

Understanding the Different Types of Crushers Agg-Net

2023年3月1日 An impact crusher uses mass and velocity to break down feed material. First, the feed material is reduced as it enters the crusher and makes contact with the rotating blow bars or hammers in the rotor. Secondary breakage then occurs as the material is accelerated into the stationary aprons or breaker plates.

What Type of Crusher Is Best for Primary

2021年3月25日 Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry to slightly wet material but not sticky material. Gyratories are

What are the types of crushers? Sandrock Mining

2021年5月27日 The commonly used crushers for sand and gravel aggregate production lines and their advantages, disadvantages, and scope of application are as follows: jaw crusher. 1. Jaw crusher. It has the characteristics of crushing ratio, uniform particle size, simple structure, reliable work, easy maintenance, and economical operating costs.

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Jaw Crushers Manufacturers, Suppliers, Exporters,Dealers

Mini Rice Mill Machines, Atta Chakki Machines, Plants, Machineries, Flour Mill Plants, Flour Mill Machinery, Emery Stones For Atta Machine, Bucket Elevators, Vibro Screens, Cyclone Dust Collectors, Manufacturer, Exporter, Supplier