iron ore crusher solution

Iron Ore Ore Crushing Solutions

2022年2月22日 iron mobile crusher is designed based on the conception of fully adapting various iron crushing condition, eliminating obstacles caused by location, environment, foundation configuration, consequently providing simple, efficient, low-cost

sbm/sbm solutions of iron ore mining crusher process

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Solution-Jiaozuo zhongxin heavy industry

2023年2月16日 Zhongxin Heavy Industrial mainly offer solution for stone production line,Iron Ore Crushing And Screening equipment and cone crusher and so on, stone

Iron Ore Beneficiation Mineral Processing

The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation),

Iron Ore Crushing Line > Ore Crushing > Solutions >

2023年2月16日 Iron ore crusher plant Project Department can offer the service as follow: Turnkey general contracting service of Iron ore crushing production line project

Iron Ore Processing,Crushing,Grinding Plant

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

Iron Ore Crushing and Screening

2023年1月6日 The jaw crusher make the first step crushing work and then through the conveyor, the crushed Iron ore will be put into the multi-cylinder hydraulic cone crusher

Iron Ore Crusher Working Process, Iron ore

2023年2月16日 Iron Ore Crusher Working Process. Iron ore dressing, according to the type and nature of ore, can have a variety of different processes. Concentrator generally used coarse crushing, middle

High rigidity Sampling Systems for Iron Ore

The only sampling method is using the cross belt sampling system to sample. For the iron ore concentrate, the GBT-10322.1-2000 standard stipulates we can use the auger sampling system to sample unless the

Iron Ore Crusher Mining, Crushing, Grinding,

2011年10月15日 Iron ore processing can be a procedure that contains explosions, shoveling, moving, crushing, grinding, pelletizing etc. Iron ore processing provides a range of coarse sizing that may produce material

Simheuristic-based decision support system for

2020年9月1日 For instance, the primary crushing stage receives the extracted iron ore directly from the mine, a simheuristic-based decision support system for choosing the optimal amount of active equipment in each stage of a crusher circuit. The solution is obtained by solving an optimization problem, in which the goal is to maximize the total

Reliable equipment for iron ore mines

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

Iron Ore Processing Plant Shanghai mpl Company

2023年2月1日 Iron Ore Processing Plant. Iron is found in the world's oldest and most widely used, is the largest amount metal, the metal consumption of about 95% of total consumption.Iron ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon content.The so-called iron ore deposits is the main

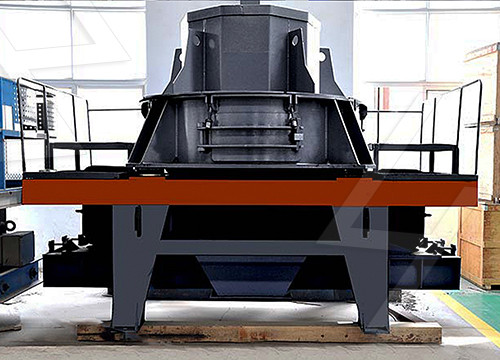

HPT Cone Crusher Popular in Metallic Mining Industry

15 小时之 When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

HOW DOES MINING EQUIPMENT WORK IN IRON ORE

2017年6月28日 Hematite and limonite, magnetite and goethite, the mining operation is extracting the rock and crushing it until the rocky deposits are evenly sized. Remember, the deposits are somewhat soft, even crumbly, but there’s raw iron trapped inside the ore. Given time, the ore will age the mining equipment, deform the system parts, and hamstring

sbm/sbm slag crusher for iron ore plant.md at main Github

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Problems and Solutions in Open Pit Iron Ore Mining

2021年5月25日 3) Stope Slope Accidents. In general, the depth of mining in open pit iron ore mines is large, so that the final slope needs to be retained for a longer period of time, and once the parameters of the open pit slope are not selected properly, it will lead to landslides and mudflow disasters, which will bring greater damage to the mining work

(New Report) Iron Ore Crusher Market 2023 Updated

2023年2月3日 Feb 03, 2023 (The Expresswire) -- Global Iron Ore Crusher MarketResearch Report 2023-2028. It Provides [Report Pages-97] Types [Primary Crushing, Secondary...

Simheuristic-based decision support system for

2020年9月1日 Simheuristic-based decision support system for efficiency improvement of an iron ore crusher circuit. Author links open overlay panel Mário S. Santos a b, Thomás V.B. Pinto a, Ênio Lopes Júnior a b, Luciano P. Cota c, The proposed solution is based on a simheuristic approach in which a simulated plant model is used to evaluate the

Reliable equipment for iron ore mines

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Iron Ore AnalysisProcess Optimization Solutions

2017年7月27日 Our solutions monitor the complete iron making processes from the direct analysis on conveyor belts towards laboratory analysis and complete automated quality control of iron ore, iron sinter, direct reduced iron, pig iron and iron ore pellets. During the entire iron ore production process, we deliver tailored analytical solutions for

Iron Ore Processing Plant Shanghai mpl Company

2023年2月1日 Iron is found in the world's oldest and most widely used, is the largest amount metal, the metal consumption of about 95% of total consumption.Iron ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon content.The so-called iron ore deposits is the main target of industrial development and

Iron Ore Beneficiation Mineral Processing

The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), and mineral dehydration (concentration, filtration, drying, etc.). The ultimate purpose of beneficiation is mainly to dissociate minerals and gangue, so as to

Github

sbm iron ore crusher plant specificationsoutotec pellet plant equipmentsspecification Solution. Outotec wins large scale iron ore plant project as well as the entire proces

HPT Cone Crusher Popular in Metallic Mining Industry

15 小时之 When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

Iron Ore: From Mining to Processing to Dust

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater than 60% iron is known