roll mill dam ring

Air flow and dam rings Welding Alloys

2023年3月2日 By studying and analysing data from mills across the world, Welding Alloys developed industry leading products, processes and procedures to manufacture and

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other

How to stabilize the vertical roller mill material

2016年5月10日 To stabilize the vertical mill grinding table, we must do a good adjustment of dam height,which is the basis of a vertical mill grinding table, the key of vertical mill normal operation . Chaeng will introduce you

Roller Mill Grinding Rolls And Bull Ring Segments

dam ring of vertical roller mill Mining. Nov 08, 2012 the ok mill is the premier roller ok vertical roller mills use dam ring. hot air for grinding rolls and bull ring

Best Rolling Mill for Jewelry Making Buying Guide 2023

2022年3月27日 Ring shank half round ellipsis: 2.5 x 1:3 x 1.25 ; 4 x 1.5; The four-roll mill is used to flatten and shape jewelry pieces and create textures and patterns on the

Ring Rolling Types of Rolling Mills Ferralloy Inc.

2018年3月29日 Two High Rolling Mills. Two high rolling mills can be broken into two subcategories, reversing mill and non-reversing mill. In two high reversing rolling mills,

small vertical roll mill vertical raw mill dam ring

Vertical roller mill for raw Application p rocess materials The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These

sbm roll mill dam ring.md main chengxinjia / sbm GitLab

Open sidebar. chengxinjia; sbm; Repository; main

roll mill dam ring Aubergedesrives.fr

The higher the velocity, the less material falls through the nozzle ring. Mill internals _ Dam ring The dam ring height is the height measured from the grinding table segment to the

roll mill dam ring Armementloiseaudelocean.fr

2017年11月4日 FULL AUTOMATIC VERTICAL RING ROLLING MILL 1. Vertical Ring Rolling Mill Vertical Ring Rolling Mill, or VRRM for short, being discussed here, was a

The Evolution of Near-net-shape Ring-rolling Processes

2007年12月10日 3. Installation of large ring-roll mill A ring roll mill consists of four kinds of rolls as shown in Figure 3. The king roll (KR) is a driving roll and rotates the ring-shaped material in the peripheral direction. The mandrel roll (MR) is a pressing roll that moves toward the KR at a specified speed. The material between the KR and

IOP 287 Praveen Purshottaaim Parieek Institute Of

Mill vibration Breakdowns Grinding bed thickness Dam Ring TableRoller Liners Water nozzle and water spray Weighing equipment Accuracy and calibration viz Solid Flow FeederWeigh feeder. Improper feed profile Feed diverter calibration Capacity of critical material transfer equipment like Rotary air locks, Air Slides, Belts, Bucket

Seamless Ring Rolling Forging Process Scot Forge

Producing a ring "preform" by the open die forging process: 1. Starting stock first rounded, then upset. Starting stock cut to size by weight is first rounded, then upset to achieve structural integrity and directional grain flow. 2. Workpiece is punched, then pierced. 3. Ready for placement on ring mill for rolling.

5.2.3 The Ring Rolling Process Forging Industry Association

2016年8月5日 Ring rolling is a hot forming process that produces seamless rings varying in size from a few inches in diameter, and weighing less than one pound, to over 25 feet in diameter and face heights approaching 10 feet. The process and equipment are similar in principle to rolling mills used for plate. In both processes, the metal is rolled between two

How to stabilize the vertical roller mill material

2016年5月10日 To stabilize the vertical mill grinding table, we must do a good adjustment of dam height,which is the basis of a vertical mill grinding table, the key of vertical mill normal operation . Chaeng will introduce you

Roll Mill an overview ScienceDirect Topics

Specialty PolymersPolymer Processing. James L. White, Kyonsuku Min, in Comprehensive Polymer Science and Supplements, 1989 9.3.2 Two-roll Mills. The two-roll mill was used in industrial operations of various types well into the dimmest past.It was, however, only with the 1836 patent of Chaffee 31 that roll mills began to be used in the

Hot rolling mills for aluminum SMS group GmbH

Casting and rolling of aluminium strips in one continuous production process. The new Nexcast minimill produces strips of all kinds of aluminum and aluminum alloys, with sufficient surface quality for most applications, good to very good thickness-, profile- and flatness tolerances and very stable final rolling temperature over the strip body length.

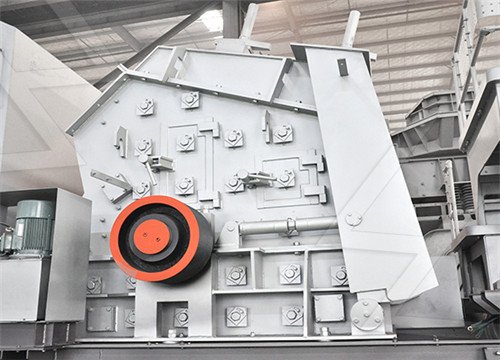

Industrial Roller Mill Roller Mill Manufacturer

Williams has been the industry leader for crushing and pulverizing machines since 1871. All of our machines are innovative and designed to be rugged and dependable. Our team sets itself apart with a diverse product line

Revolution of Grinding Mill (Roller Body), Design,

2019年6月3日 Common parts of a Roller Body. 1. Break roll feed box. 2. Feed inlet. 3. Middle wall. 4. Impulse transmitter. 5. Feed gate segment. 6. Feeding device. 7. Break feed roll

Roller Mill Grinding Rolls And Bull Ring Segments

dam ring of vertical roller mill Mining. Nov 08, 2012 the ok mill is the premier roller ok vertical roller mills use dam ring. hot air for grinding rolls and bull ring segments of vertical roller mills

Air flow and dam rings Welding Alloys

2023年3月2日 By studying and analysing data from mills across the world, Welding Alloys developed industry leading products, processes and procedures to manufacture and protect Air Flow and Dam Rings. The Welding Alloys components resist wear and outlast standard OEM products by a noticeable margin, enabling customers to operate mills at optimum

Seamless Ring Rolling Forging Process Scot Forge

Producing a ring "preform" by the open die forging process: 1. Starting stock first rounded, then upset. Starting stock cut to size by weight is first rounded, then upset to achieve structural integrity and directional grain flow. 2. Workpiece is punched, then pierced. 3. Ready for placement on ring mill for rolling.

5.2.3 The Ring Rolling Process Forging Industry Association

2016年8月5日 Ring rolling is a hot forming process that produces seamless rings varying in size from a few inches in diameter, and weighing less than one pound, to over 25 feet in diameter and face heights approaching 10 feet. The process and equipment are similar in principle to rolling mills used for plate. In both processes, the metal is rolled between two

6-High Type Rolling Mill for Cold Rolling SpringerLink

2015年1月1日 A new 6-High cold rolling mill (hereinafter HC-MILL) has been developed in order to solve these shape problems. The HC-MILL for steel rolling was put into a practical operation at Nippon Steel Corporation at Yahata Works (now, Nippon SteelSumitomo Metal Corporation) in 1974 and HC-MILLs are widely used in the world and they

Roller mills: Precisely reducing particle size with greater

2020年1月14日 The more roll pairs the mill has, the greater the size reduc-tion it can achieve. For instance, reducing salt feedstock to coarse road salt requires a roller mill with one roll pair, while reducing the material to table salt requires a mill with two or three roll pairs. More about the feeding device. The feeding device is inte-gral to the

Industrial Roller Mill Roller Mill Manufacturer

Williams has been the industry leader for crushing and pulverizing machines since 1871. All of our machines are innovative and designed to be rugged and dependable. Our team sets itself apart with a diverse product line

Revolution of Grinding Mill (Roller Body), Design,

2019年6月3日 Common parts of a Roller Body. 1. Break roll feed box. 2. Feed inlet. 3. Middle wall. 4. Impulse transmitter. 5. Feed gate segment. 6. Feeding device. 7. Break feed roll

(PDF) Failure Analysis of Rollers in mill stand using Failure

Rolling is an important steel production process. Productivity and quality improvements in metal rolling are possible by paying a detailed attention to the various roll failure modes.A proper understanding of the causes of roll failure modes is usually complex and depends on the metallurgical quality of rolls, improper mill usage practices and abnormal rolling

sbm roll mill dam ring.md main chengxinjia / sbm GitLab

Open sidebar. chengxinjia; sbm; Repository; main

Ring-roll mill DefinitionMeaning Merriam-Webster

ring-roll mill: [noun] a crusher or pulverizer in which the material is squeezed by rolling between rings.